The Biggest Problem Facing Helium Leak Testing Today

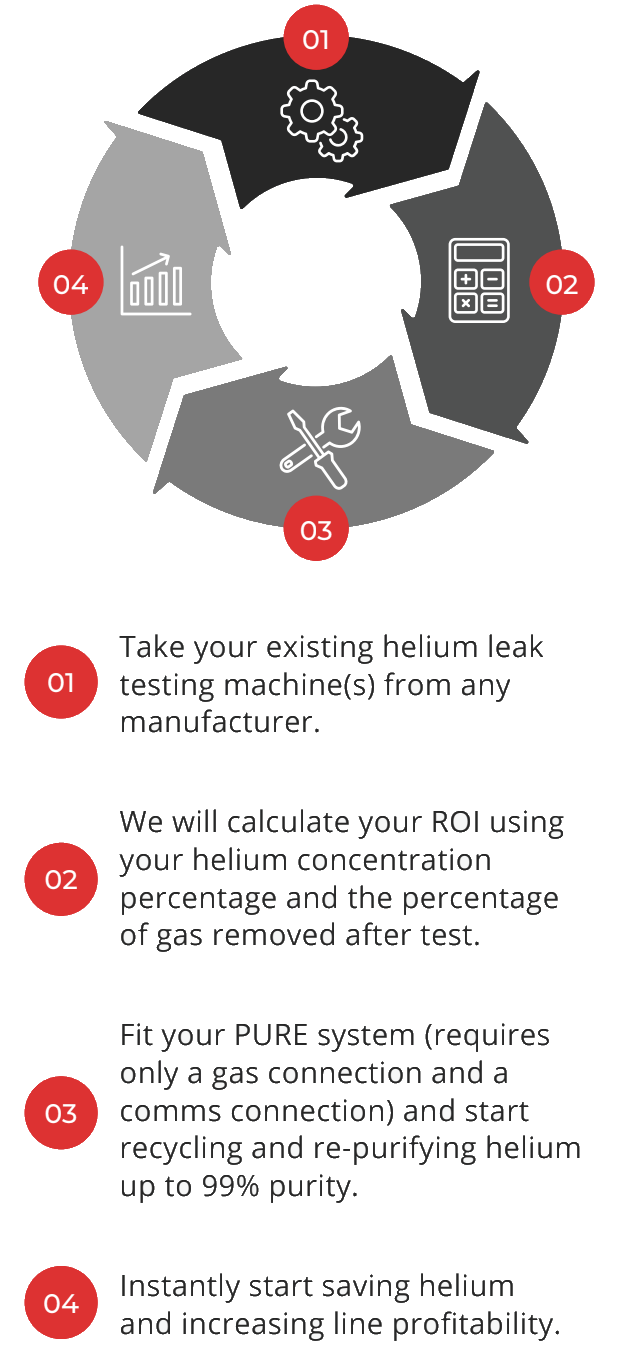

Test gasses can only be diluted so far before the integrity of the test is compromised, and having to buy more helium for every test only pushes the helium shortage further and prices higher. Now more than ever, reusing helium is of paramount importance.

Historically, it has been a challenge to implement a helium recovery system retrospectively, particularly in low-pressure applications such as fuel or gas tanks. This is due to helium dilution in the test being unsustainable when recycled, or subsequent fresh helium top-up draining away any cost savings.

Return on Investment

Scenario One:

A test on a 181-litre volume pickup truck tank. The tank was pre-evacuated to 29 mbar and injected with 120 mbar of fresh helium, resulting in a 77% helium concentration during the test. After the test, the tank was evacuated to 55 mbar and the evacuated gas exhausted from the system.

After implementing PURE, the exhausted gas was recaptured and the 77% helium mix was re-concentrated to >99%. This gas was fed back into the machine at 2 bar.

Implementing PURE to reduce helium usage saved $0.27 per tank, resulting in a 1.6 year payback.

Scenario Two:

A test on a 90-litre volume car tank. The tank was pre-evacuated to 6 mbar, and 74 mbar of fresh helium was injected on top, meaning a 91% helium concentration was used during the test. Post-test, the tank was evacuated to 31 mbar and the evacuated gas exhausted from the system.

Using PURE, the exhausted gas was captured and the 91% helium mix was reconcentrated to >99% and fed back into the machine at 2 bar. Using PURE saved $0.11 per tank and demonstrated a 2.0-year return on investment to reduce the cost of helium leak testing.