Who knows which direction the automotive industry will go? Many people within the industry believe that battery electric vehicles are here to stay, while others believe that they will be a stopgap before hydrogen-powered vehicles become more commercially viable.

If we move towards hydrogen-powered vehicles, then the industry will have to face new and difficult challenges, including leak testing the high-pressure composite tanks. Each tank must be tested to R134 and EC79.

Let us introduce you to the H²Safe range by VES.

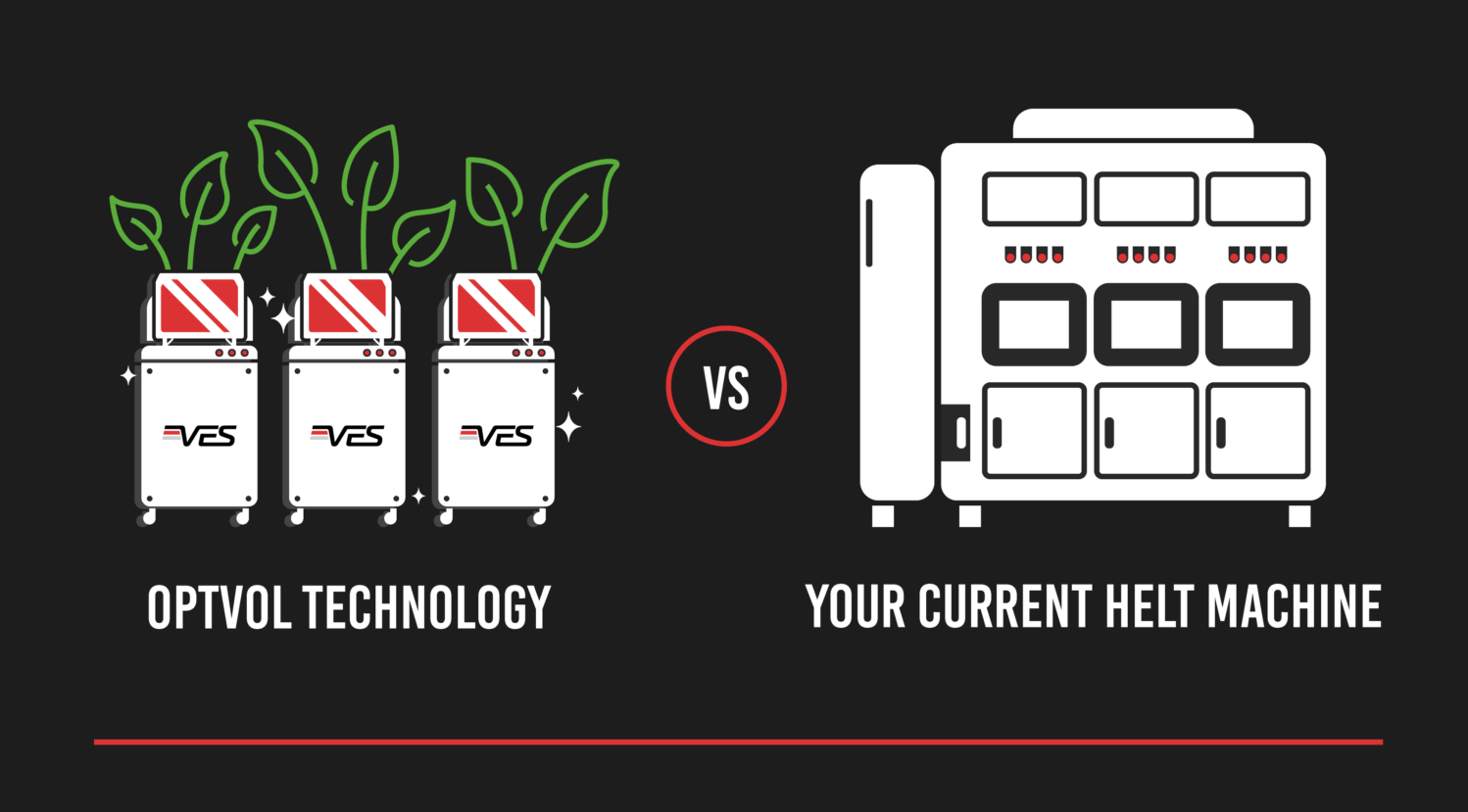

Each machine has three different elements – 1) leak testing equipment, 2) high-pressure generation/recovery and 3) pressure containment, with different elements making up the modular designed machine, tailored to each individual customer’s needs.

VES have developed machines and partnerships with global leaders in the different elements to provide the industry with an all-in-one solution to deliver the best-in-class results. Starting with a vacuum drying station to meet stringent moisture content requirements; moving on to a fully automated quantitative leak test machine with built-in point detection to meet the required leak rates and cycle times.

Many believe testing with a sniffing probe and robot will provide an accurate and reliable leak test. However, here at VES, we have provided evidence that accumulation testing is the best and most accurate way to leak test high-pressure tanks. Accumulation testing can give the operator a quantitative result to show the true leak rate of the tanks and to comply with international regulations.

This machine tests the vessels in optimal conditions using either forming gas or helium mixed gas. The H²Safe tester provides accurate, repeatable and reliable results at a low cost; VES have also introduced different testing gases and been able to provide a solution that is up to 94% cheaper per test piece than traditional 100% helium.

VES can supply a full H2Safe system with full traceability to give you and your customers the peace of mind that the product is fully leak-tight.

In everything we do at VES, maintaining the highest standards of safety is our highest priority. We have the full package of machines to meet all the international regulations and requirements for the full range of pressure vessels (Category I to IV) to ensure that all pressure vessels, including hydrogen tanks and fuel cells, meet the global regulations.

Contact us for more details.