The subtle art of leak detection, often unnoticed, holds a significant role within the manufacturing industry.

In a time of escalating technological advancement, spotting even the minutest leak in a system is essential for preserving product integrity. This is where the role of helium leak detection becomes significant. This technology is offered by a select few companies that are experts in helium leak testing applications. This sophisticated testing methodology enables the identification of tiny leaks, which could potentially cause severe disruption to your systems.

Among the handful of experts, VES has earned a reputation for its substantial experience in a number of sectors, having delivered helium leak detection systems to many of the world’s largest manufacturers for nearly three decades.

The Science Behind Helium Leak Detection

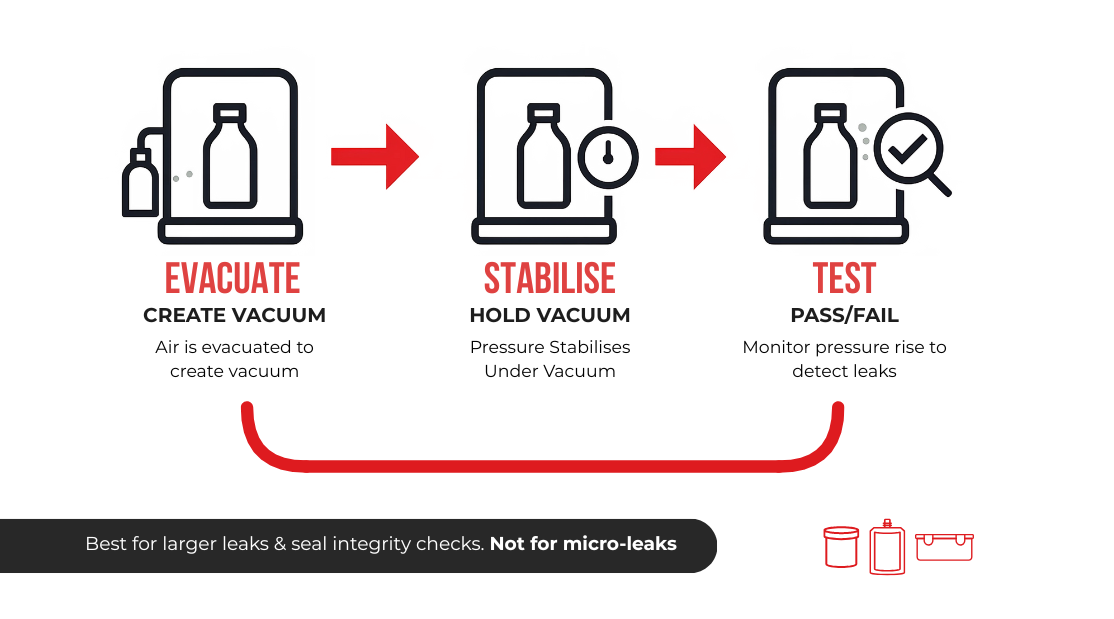

Helium leak detection is a non-invasive testing technique that uses helium in various ways to spot leaks untraceable by less advanced methods. The process involves subjecting the component under scrutiny to helium and then using mass spectrometry to measure the amount of helium leakage at a molecular level. The most thorough technique employed is Hard Vacuum (Chamber) Helium Leak Detection, which consists of five primary stages:

- Stage 1: Eradicating the Helium Background

Given the presence of 5ppm of helium in atmospheric air, it is paramount to eliminate any residual helium from the testing environment. This is done by lowering the pressure in the test piece and the chamber to about 1 mbar, effectively removing any helium partial pressure from the environment. Leak testing can only start after achieving a stable background reading.

- Stage 2: Creating a Pressure Differential

The formation of a pressure differential is essential to direct the leak path correctly. This principle is ubiquitous in leak detection – as commonplace as observing a tap drip or watching bubbles from a submerged bicycle inner tube. In a hard vacuum chamber machine, this is achieved by backfilling helium to the appropriate test pressure after Stage 1.

- Stage 3: Feed the Helium to the Mass Spectrometer

This stage is critical as traditional vacuum pumping systems decrease speed at lower pressures, which can impact the response time to detect any leakage from the test piece by the mass spectrometer. Factors such as incorrect vacuum conductance, slower pumping speed, and larger chambers can result in missed leaks. Hence, calibrating your system to ensure a proper response time is necessary.

- Stage 4: Setting a Leak Rate Threshold

Our favourite saying at VES is that everything leaks. All you can do is guarantee your product meets a certain threshold. Therefore, knowing your leak rate threshold is critical, and this is where EN 1779 comes into play – it evaluates hard vacuum leak detection to detect leakage to 10-9 Pa⋅m3/s. Depending on your industry, your leak rate could relate to hole size (automotive), weight loss per annum (HVAC), or the size of a virus (medical device). If your test piece’s leakage is below your set limit, it passes!

- Stage 5: Venting

Venting, the final stage, is critical to protect thin-walled products that are vulnerable during this phase. Any mismanagement of the pressure differential can cause your product to implode or explode. This process is carefully handled by a PLC programme and often tracked by deflection sensors in real-time.

While helium leak detection may seem like a niche domain, it plays a significant role in the world of manufacturing. As we say at VES; “Everything leaks.” Our duty is to ensure these leaks fall within acceptable limits, thereby maintaining product quality and performance.