Residential Air Conditioning

Vacuum Engineering Services understands the challenges the HVAC industry is facing with increasingly strict SEER regulations that increase product complexity and has developed innovative leak testing solutions to solve them.

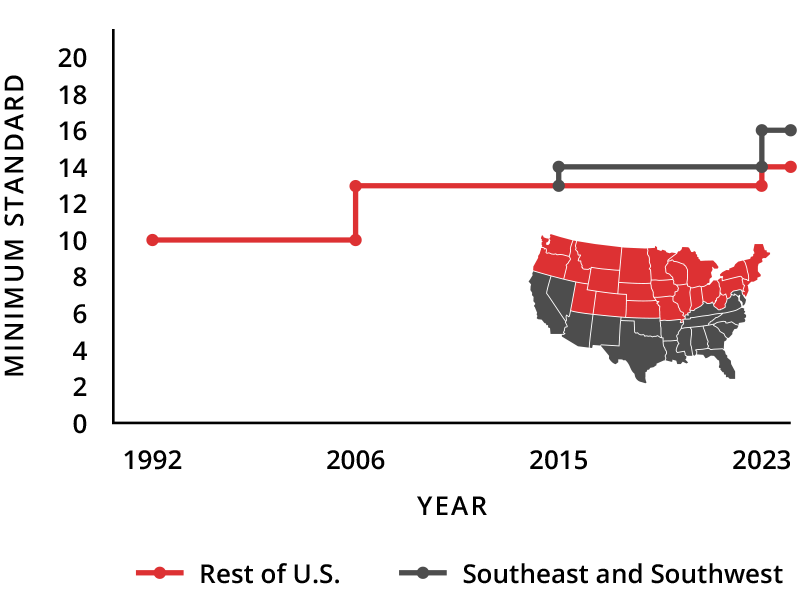

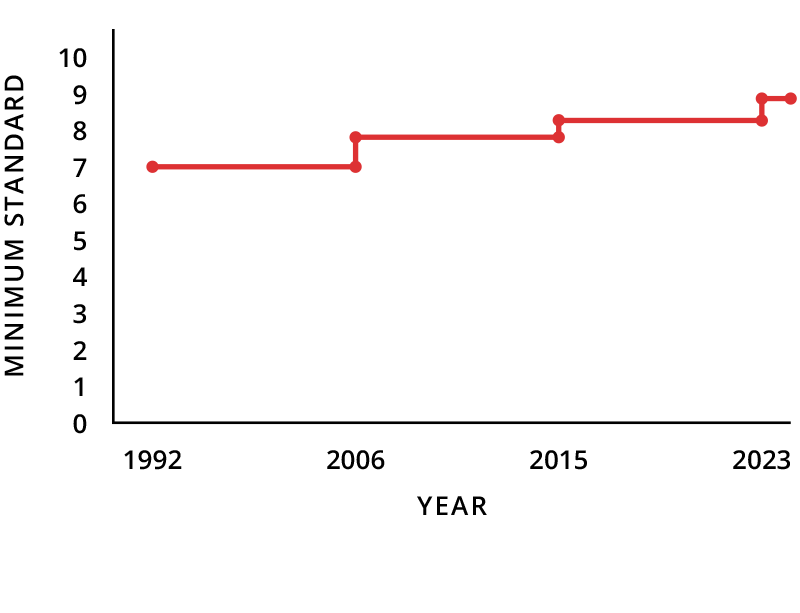

The new standards effective in 2023 require a seasonal energy efficiency ratio (SEER) – a measure of a system’s cooling performance – of no less than 14 SEER for residential systems in the northern part of the United States and 15 SEER in the southern part of the United States, where cooling loads are a larger share of home energy use. Higher SEER ratings indicate more energy-efficient equipment.

Efficiency requirements for residential central AC and heat pumps to rise in 2023. Seasonal energy efficiency ratio (SEER) shown above.

Challenges

Vacuum Engineering Services has real production ready solutions to ensure your company remains an Industry Leader in Product Quality, Throughput, and Overall Cost in producing your HVAC Products even with SEER’s Challenges.

VES Systems Can Reduce Factory Footprint by consolidating test stations. Imagine consolidating Pressure Decay, Burst Test, Fine Leak, and Recovery in one cycle!

These Challenges Include:

- Increased surface area of condensers and evaporator coils to achieve higher efficiencies that increase number of leak points due to increased number of tubes/brazed joints

- Increased assembly floor complexities such as:

- Reduced throughput due to more failures

- Increased floorspace demands due to more testing stations

- Increased repair and rework due to new brazing processes

5 Reasons to Contact VES Today

Maximum Efficiency

A customer consolidated 3 tests and recovery in the same station saves approximately 60 seconds of cycle time! (*dependent on product)

Proprietary Technology

Proprietary technology eradicates false failures due to previous failed parts

Increased Speed

Intelligent rework stands utilize helium leak test data to speed up the rework process

Integrated Testing

Higher pass rates on final assemblies due to integrated testing and pre-testing of parts. Options for lower cost/lower sensitivity tests for component assembly

Rapid Installation

Rapid Machine Install by VES, less than 1 week (dependent on site utilities). This saves your company money with less manufacturing facility downtime to install new equipment!

- 19% Reduction in floorspace on average

- 50% Reduction in Operators/$90k savings per year

- 65% Decrease in gas cost

- 20% Less initial Capex cost 20% than traditional leak test solutions

Contact us today and one of our industry leak test experts will provide your company with a production line audit to create customized solutions for your manufacturing lines.