Hydrogen Tanks

VES have developed the best in class leak detection machine to meet all the demands of testing high pressure hydrogen tanks. R134A, AC19 and IP67 regulations are all met with VES equipment. Using the knowledge and experience from over 30 years of manufacturing leak detection equipment, VES have developed a unique quantitative leak test for all high pressure tanks.

As the world moves away from internal combustion engines and traditional fuel tanks; high pressure hydrogen tanks are the new energy storage. VES have designed a number of machines for Hydrogen fuel tanks. These tanks work at extremely high pressures and high volumes. Leak testing comes with some very unique challenges that can be broken down into three different areas:

Hydrogen

Vacuum Engineering Services have worked with their partners to create the VES New Energies solution. Combining all the history and experience in a leak test station with new high-pressure boosting/recovery systems and safety containment systems.

The New Energies product range was developed by VES to accommodate 900 bar testing of hydrogen tanks to ensure no leakage occurs. New Energies offers a 100% non-operator dependant qualitative test that is safe. Get in touch to find out more.

VES also noticed a poor MSA scoring on traditional pressure decay testing of fuel cells, costing manufacturers thousands of pounds in re-work and re-test fees. We implemented a tracer gas test system to minimise footprint and increase production throughput.

With everything we do at Vacuum Engineering Services, safety is our highest priority, maintaining the highest standards throughout our facilities. All pressure vessels including hydrogen tanks and fuel cells must meet the global regulations. Vacuum Engineering Services have experience in meeting all EU and global standards. Feel free to contact us to discuss further.

VES New Energies Solution

At VES we have designed a full package of machines to meet all the requirements for leak testing these high-pressure tanks. Starting with a vacuum drying station to meet stringent moisture content requirements. Moving on to a fully automated accumulation machine with built in point detection to meet the required leak rates and cycle times.

Accumulation machines work in atmospheric conditions using either forming gas or tracer gas; working without a vacuum chamber an accumulation tester provides accurate, repeatable and reliable results at relatively low cost. While VES have also introduced different testing gases, been able to provide a solution that is up to 94% cheaper per test piece than traditional 100% helium.

A unique design, developed in house at VES, specifically for high pressure applications (including Hydrogen and CNG tanks). The H2 Safe machines have been designed to incorporate three different elements:

Fuel Cells

Fuel cells are made up of layers of material: An Anode, Cathode and Electrolyte. To ensure leak tightness of the cells and optimise performance, a helium leak test must take place. Legalisation and best practice require parts to be tested to a leak rate of 2 x 10-5mbar.l/sec. Vacuum Engineering Service have designed machines for both cells and modules for Hydrogen and Methane Fuel Cells.

Hydrogen Fuel Cells

VES have developed the most efficient and effective methods for leak testing fuel cells. Using an aluminium chamber design with a volume optimised solution and state of the art tooling, all fuel cells can be leak tested to industry standards.

Hydrogen fuel cells are used in many modes of transport, including cars, buses, lorries and boats. Bespoke leak detection equipment from VES is tailored to your every need.

Want to know more about leak testing fuel cells? Sign up below for more information.

Battery Cells

How does the industry leak test batteries and battery cells? The industry has many methods of leak testing batteries and cells with no common leak rate standards and regulations. As the automotive industry moves away from the conventional internal combustion engine to the battery electric vehicles, accurate battery cell leak detection is increasingly important. Battery cell production has increased with an approximate 10% CAGR. Car battery leak testing requires dedicated and reliable equipment. Vacuum Engineering Services are a world leader in leak testing technology that can guarantee leak tightness across the full range of battery products.

Leak testing battery cells is necessary to stop water and lithium mixing. Lithium reacts intensely with water, forming lithium hydroxide and highly flammable hydrogen. Stopping this water ingress is necessary to maintain product integrity, all parts should be tested to a leak rate of 2 x 10-5 mbar.l/sec. All battery cells must now comply with IP67 or IP68. This states there is no water ingress for 30 minutes in 1 metres of water and no water ingress for 30 minutes in 1.5 metres of water, respectively. This is the equivalent of a leak rate well below 1 sccm, therefore all battery cells must be helium leak tested. Pressure decay and bubble testing will not give battery manufacturers the required accuracy to comply with IP67 and IP68.

Vacuum Engineering Services can leak test all battery cells (pouch, cylinder and prismatic), modules and systems to meet customer specific leak rates and requirements.

Batteries

Battery testing to IP67 in avoidance of ingress is essential for safety and efficiency of the electric drivetrain. Literature suggests that IP67 can only be attained through tracer gas leak testing as other methods are unable to reach the required sensitivity. Not only are the battery cells and modules tracer gas tested, but the largest automotive suppliers tracer gas test the battery coolers also.

Want to know more about leak testing battery cells? Sign up below for more information.

Battery Coolers

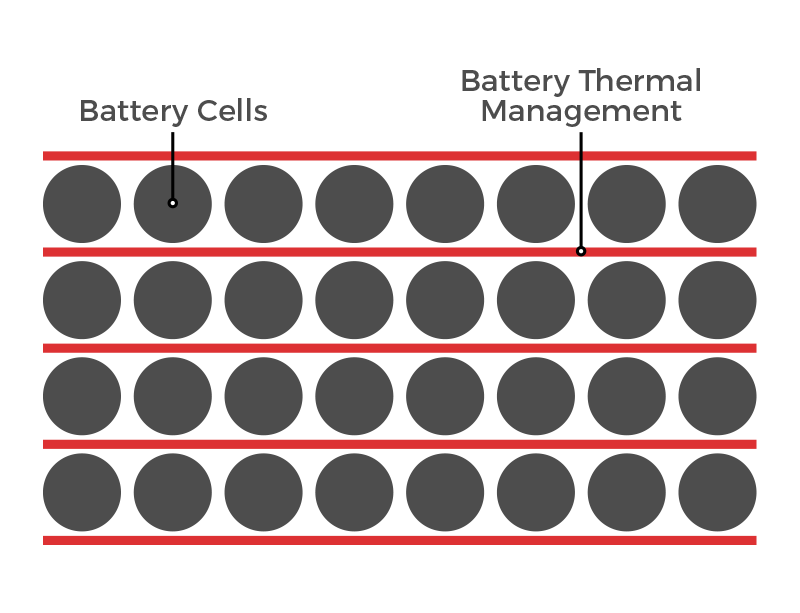

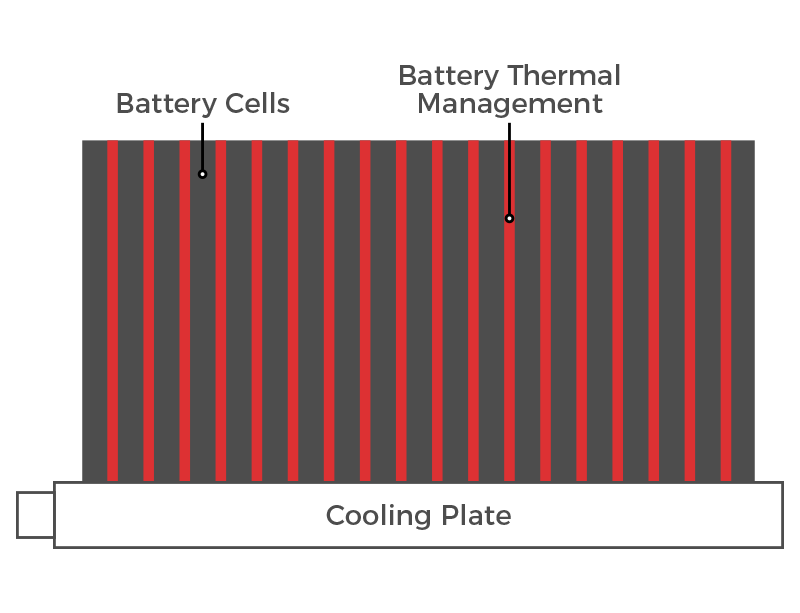

Vacuum Engineering Services have the experience and expertise to deal with any of your leak detection needs. At VES we work with all parties to provide the best possible solution for the application. With electric cars and vehicles seeking longer range; higher powered batteries are becoming necessary. Therefore, battery cooling is a must. Battery thermal management systems are essential to maintain the battery cells performance and prevent thermal runaway.