VES Automation – The Benefits of Automating Leak Testing with Robotics

Automating leak testing and integrating robotics can revolutionise product assembly and quality assurance in any production process flow. Whether it's upgrading a manual task through autonomous robotics or implementing cobotics (collaborative robots) that work alongside people, automation can significantly enhance efficiency and reliability. By innovatively automating part or all of the leak detection process, VES automation solutions streamline operations, often with little or no human intervention.

With years of expertise in leak testing, we are uniquely equipped to apply our knowledge to both current and emerging technologies, as well as new manufacturing processes that require tailored automated solutions.

As your trusted partner in leak testing and leak detection, we help automate your processes to deliver improved quality, speed, and accuracy. This, in turn, boosts health and safety standards for your team, enhances productivity, and increases return on investment—ultimately giving your business a competitive edge, no matter what you produce.

Automate Your Leak Testing and Leak Detection Process

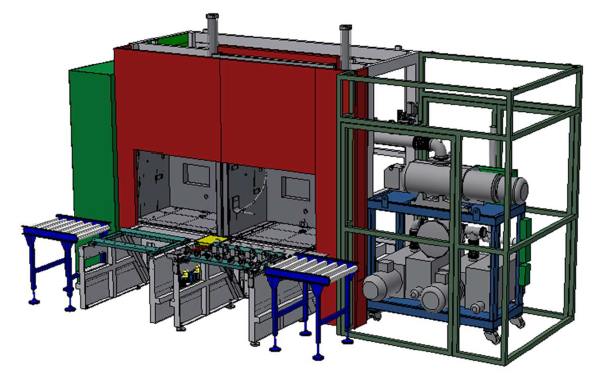

We work collaboratively with our customers to deliver tailored automated leak testing solutions. Whether you need a standalone test cell or a fully integrated assembly line with multiple leak detection systems, we provide seamless, efficient automation to meet your specific production needs

Why Opt for VES Automation?

Our standardised modular solutions are designed to support modern production processes that require robots, palletised assembly or rotary indexing tables.

It features standard frames and a flexible, scalable controls architecture, creating a versatile, modular platform, available in single or multi-station configurations.

Accommodating a wide range of processes, including automatic screwdriving, dispensing, laser marking, vision inspection, end-of-line testing, pick-and-place operations, leak detection testing and assembly.

Our modular design allows additional stations to be seamlessly integrated as production demands grow. Interchangeable tooling across all our solutions enables quick and easy updates for existing products or new variants.

Projects

Leak Testing Automotive Plastic Hose Assembly Variants

The result was a transformative, future-proof solution that not only achieved all specification targets but also enhanced the customer’s operational capabilities and strengthened their position in the automotive market.