In the automotive industry, leak testing is a critical process for ensuring the safety and reliability of a vehicle. It involves detecting and identifying any leaks that may occur in various components of the vehicle, such as fuel systems, air conditioning systems, and brake systems. Leak testing is a necessary step in the production of automobiles and is required by regulatory bodies to ensure that vehicles meet safety and environmental standards.

Helium leak testing is a highly effective method of detecting leaks in a wide range of automotive components. This method involves using helium as a tracer gas to identify the location and size of a leak. The helium gas is introduced into the component being tested, and a helium detector is used to detect any gas that has escaped.

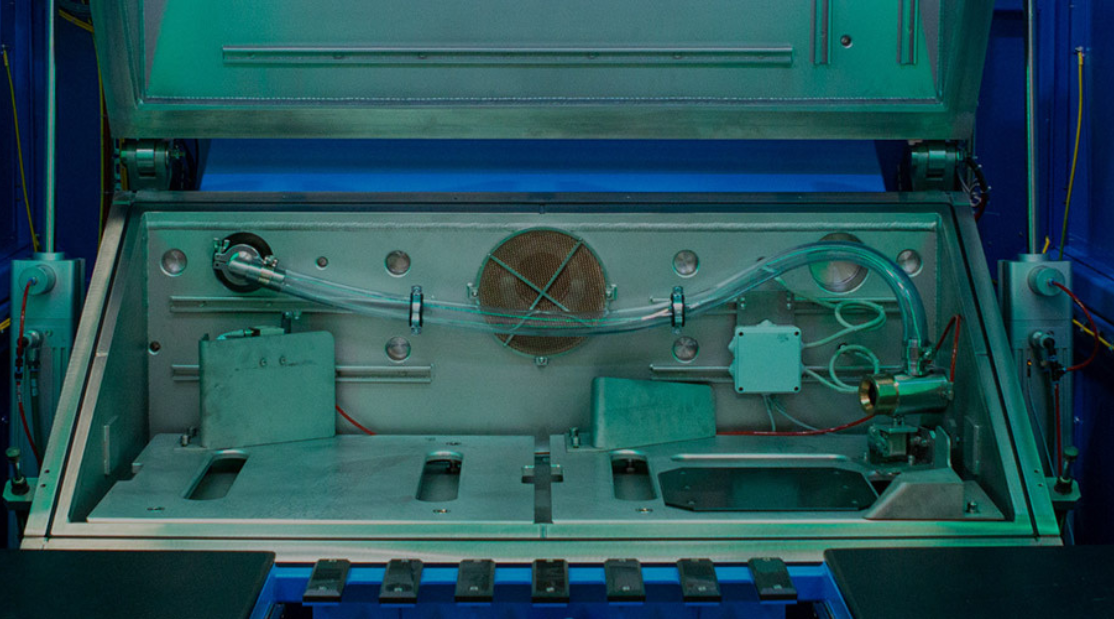

Helium leak testing machines are highly sophisticated and complex systems that require specialised knowledge and expertise to operate effectively. They can include various other features, but always contain a helium gas supply, a vacuum pump, and a helium detector. These components work together to ensure that the helium gas is introduced into the component being tested and that any leaks are accurately detected.

One of the key advantages of helium leak testing machines is their high sensitivity. They can detect leaks as small as 10^-7 cc/sec, which is crucial in the automotive industry where even the tiniest leaks can lead to significant safety and environmental issues.

However, despite the effectiveness of helium leak testing machines, there are still several common challenges that manufacturers may face when using them. Here are some of the most common challenges and how to overcome them:

Tooling Compatibility: One of the biggest challenges in leak testing is ensuring that the tooling used to test different components is compatible with the leak testing machine. Manufacturers must ensure that the tooling used is designed specifically for the machine being used to ensure accurate results.

Leak Location: Locating the exact location of a leak can be challenging, especially in complex components such as fuel systems. Manufacturers must ensure that the testing machine used is capable of accurately locating leaks and that the operator is trained to use it effectively.

False Positives: Another challenge in leak testing is the occurrence of false positives. This can occur when the testing machine detects helium gas that has not escaped from the component being tested. Manufacturers must ensure that the testing machine is calibrated properly to minimize the occurrence of false positives.

To overcome these challenges, manufacturers must ensure that their leak testing machines are designed to meet the specific requirements of their production processes. They must also ensure that their operators are properly trained in using the machines and that they have access to the necessary resources and support to ensure accurate and effective testing.

Leak testing machines are essential in the automotive industry for ensuring the safety and reliability of vehicles. Helium leak testing is a highly effective method of detecting leaks in various components and is widely used in the industry. However, there are still several common challenges that manufacturers may face when using these machines, and they must take steps to overcome these challenges to ensure accurate and effective testing. As experts in helium leak detection, VES can provide customised solutions and support to help manufacturers overcome these challenges and ensure the highest quality testing.