A fully integrated, single-chamber leak detection system had its factory acceptance test witnessed remotely by our customer, before being shipped from our Manchester facility to its destination in the United States.

This leak detection system is part of the development of durability vehicles and simulator test rigs for key life tests, conducted before, during, and after, by a global manufacturer and supplier of automotive parts.

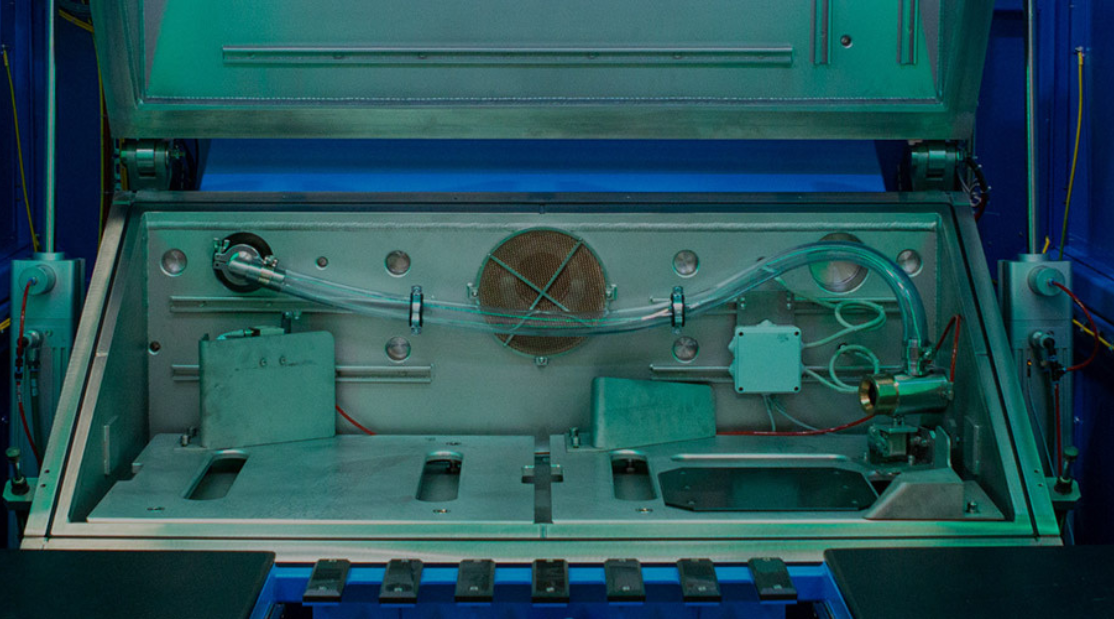

The system is designed to leak test air spring assemblies and has multiple fixture points to adapt to the various sizes of components for testing. Our engineers demonstrated the capabilities of the leak system, showing its ability to consistently distinguish between pass and fail samples.

The system includes a manual chamber door, manual connection to the assembly, programmable test pressures and cycles for testing the structural integrity of the component parts, along with adjustable leak rates.

For assistance with any of our advanced automotive leak detection systems or customised solutions, please contact our highly experienced sales engineers to discuss further.