At VES, we continually strive to:

- Improve build quality

- Increase the serviceability of our machines

- Standardise products

- Reduce lead time and increase productivity

In order to achieve this, VES use key Japanese Lean Manufacturing principles. Lean Manufacturing is a systematic method of manufacturing originating from the highly-efficient Japanese manufacturing industry. It focuses on minimising waste (無駄 muda) without sacrificing productivity. Lean principles also take into account waste created through overburden (無理 muri) and unevenness in workloads (斑 mura).

How VES reduces Muda, Muri and Mura

In the context of building machines, VES considers Muda to contain not only physical waste, but also wasted time. Here is an example of what we do to create the best product possible:

Modularisation of Machines

Our Machines can be split into 4 main modules: Vessel Module, Electric Cabinet, Pump Group, and Valve Plate. Each specific module is now created in specific build bays equipped with the correct tools. Modules of machines can refine the drawings, which lessens issues and reduces design time.

Workshop Layout Overhaul

Build Bays were created to accommodate the building and integration of standard, modularised items.

The 5S Culture

VES also promote the 5S culture, which introduces structure and improves the environment and operator morale. 5S identifies other areas of waste including:

- Location and availability of the correct tools

- Location and availability of consumable components

- Location and organisation of Kits

- The "Tidy Space, Tidy Mind" Principle

- Generating a culture of looking after the workspace

Layout Before Lean Manufacturing

Before implementing Lean Manufacturing, the workspace was messy, unorganised, and inefficient. Tool chests were located entirely on one side of the factory, and part storage was located on the other. The quality of the lighting was low, and there was a lot of wasted space.

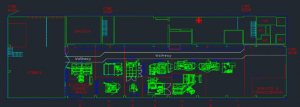

Layout After Lean Manufacturing

After we implemented Lean manufacturing, the workspace was transformed. The new layout allowed better Health and Safety standards, and better space optimisation. Furthermore, we improved the quality of our machinery, and of the work environment as a whole by improving lighting, heating and ventilation.

Results

| Average Time | Pre-lean Manufacture | Post-lean Manufacture |

|---|---|---|

| Module build time | 4 days | 2 days |

| Modular Machine Manufacture | 4 weeks | 2 weeks |

| Lead time from order to dispatch (design, procurement, manufacture and commissioning) | 25 weeks | 14 weeks approximately |

Since introducing Lean Manufacturing principles, we have vastly improved our lead times – for example, our average module build has been reduced from 4 to 2 days. As a result, a full build of a Standard Fuel tank machines, which initially took 4 weeks, now takes only 2 weeks. This means we can now design, integrate and dispatch machines in less than 14 weeks.

Want to know more about our machines? Got a question about leak detection? Don't hesitate to Contact Us.