Amidst the ongoing climate crisis, the fuel cell industry and hydrogen sector are more important than ever. These sectors provide the world with the vital opportunity to become less reliant on carbon and fossil fuels. Accurately testing fuel cells is vital for yielding Watts in a clean and environmentally friendly way.

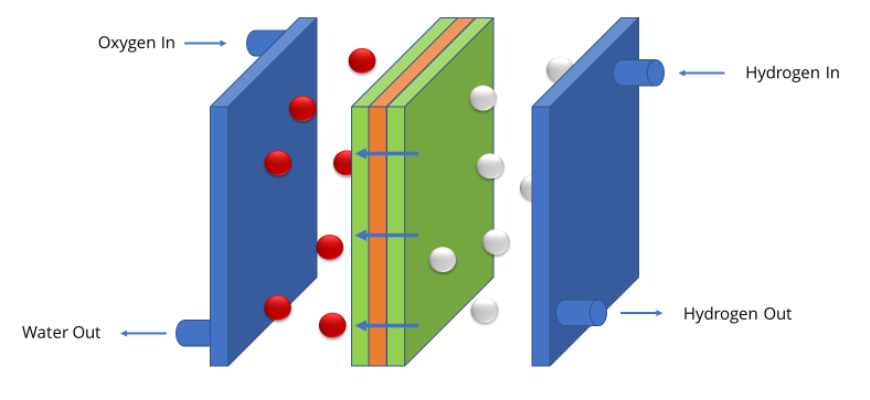

Structurally, fuel cells are made up of an anode-cathode and electrolyte membrane. Hydrogen is passed through the anode and oxygen through the cathode. At the anode, hydrogen is stripped of electrons. Then, the partially charged hydrogen atoms (protons) pass through the membrane and combine with the oxygen to form water. The free electrons are forced into a circuit to form clean electricity.

There are many advantages to using fuel cells. Their emissions are low-to-zero and they provide a reliable energy source. Fuel cells are both durable and scalable. However, many fuel cell manufacturers have come to VES with one very big problem – leakage.

Leakage has proved catastrophic to the success of fuel cells – one large manufacturer mentioned a success rate in their pressure decay test station of below 60%. Pressure decay is clearly not working for the fuel cell industry.

Leak testing fuel cells

After speaking with many industry leaders about the issue, VES have developed the ideal solution for leak testing fuel cells and stacks – OptVol.

This new leak testing technology from VES is an all-in-one machine with a small footprint. Features include easily interchangeable tooling for different product variants and a lightweight design. This allows for ease of movement between production lines as production increases.

Using the traditional hard vacuum tracer gas method provides the manufacturer and their customers with the knowledge that the product and stack have been leak-tested to 1e10-5 mbar.l/sec.

VES have over 25 years of experience in leak testing many different products. We have combined our knowledge and experience to provide the industry with the best-in-class leak testing technology, including maintaining the optimal pressure differential for the fuel cells. VES have become a world leader in maintaining the pressure differential for a number of different products, including fuel tanks, and now fuel cells.

With everything we do at VES, safety is our highest priority. As part of maintaining the highest of standards throughout our facilities, all fuel cells and stacks must meet global standards and regulations.

Want to know more? Contact Us today.