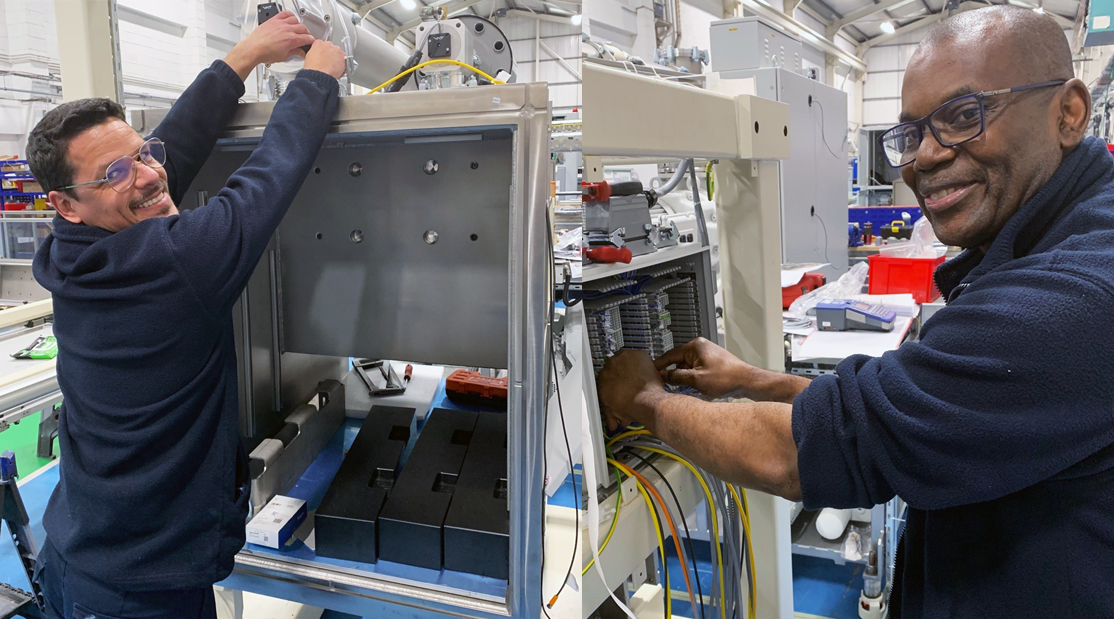

Our experienced electrical engineers Wendel (pictured left) and Oliver (pictured right), here working hard wiring several helium leak test systems designed for production line testing new aluminium coils for advanced HVAC systems, for a manufacturing facility in Mexico for a globally renowned heating, ventilation and air conditioning company.

The leak detection systems will include several hard vacuum stations equipped with barcode scanners along with remote monitoring software for any potential online troubleshooting. These stations are designed to verify the leak tightness of specific components and meet stringent R32 leak standards. A helium recovery system shared between stations for reclaiming and reusing the costly gas will also be provided.

There’s also sniffer repair stations, where the aluminium coils will be charged with gas and sniffed manually with the sniffer for locating any specific areas of potential failure. Nitrogen charge leak check stations will also be produced to stand downline of the helium leak test stations to aid with the detection of large leaks.

All our electrical engineers play a crucial role in applying their knowledge and experience with developing, testing and supervising many aspects of producing of our leak detection equipment and various complex modules designed for customer specific applications.

For assistance with our safe, reliable and efficient leak detection systems designed for testing aluminium coils for HVAC systems, please contact our sales engineers by email at sales@vac-eng.com