Helium Leak Testing by VES

World-renowned expertise. Over 1,600 systems deployed globally.

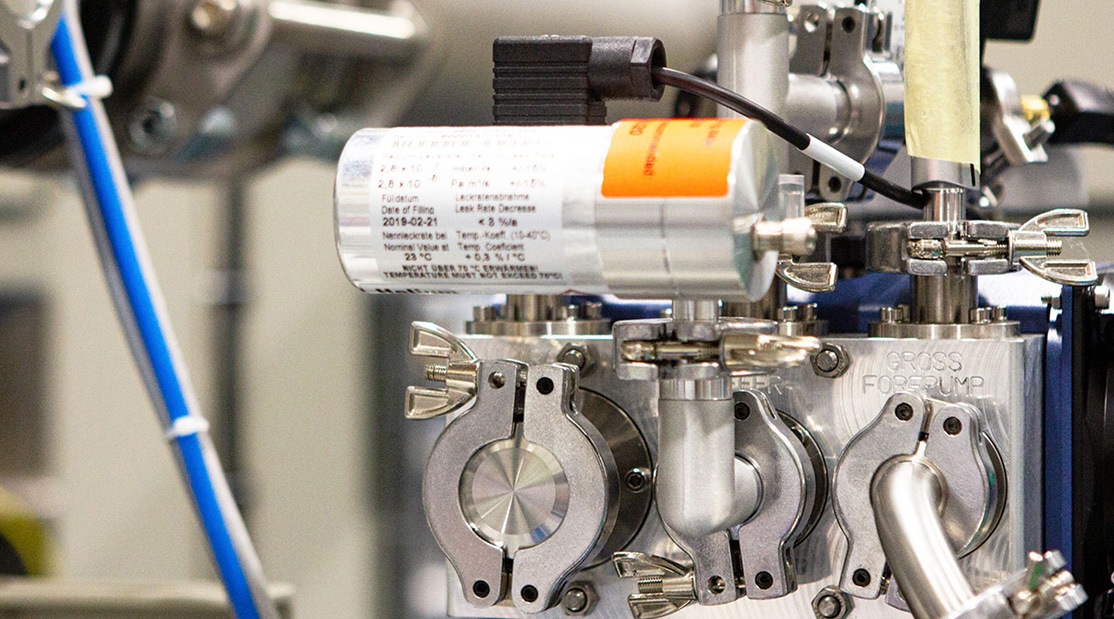

Precision Helium Leak Testing for Automotive, HVAC and Clean Energy Sectors

Welcome to VES Helium Leak Testing

Global Leaders in Precision Helium Leak Detection Systems.

With over 1,600 systems installed worldwide, We are a trusted leader in advanced design and manufacturing of leak detection systems. From vacuum chamber and accumulation to sniff and spray testing, our helium-based technologies deliver unmatched accuracy, repeatability, and reliability, trusted by industries from automotive to medical.

We offer fully bespoke helium leak testing systems as well asOptVol—a compact, all-in-one system that's 9% faster than traditional setups and cuts operational costs by up to 65%, and Accuro, a vacuum-free system that detects leaks down to 1.0e-03 mbarL/s without being affected by temperature changes. Backed by our high-performance Helium Leak Detection Machine, we can provide smart, scalable solutions built for real-world production demands.

Custom Leak Detection

Engineered for precision and reliability, our Custom Helium Leak Testing Machines deliver outstanding sensitivity, repeatability, and durability

OptVol Leak Detection

OptVol is a compact, all-in-one helium leak testing solution. Capable of detecting leaks as small as 5.0e-06 mbarL/s,

Accuro Leak Testing

Accuro is a high-performance mass spectrometry leak testing system designed to work without a vacuum setup.

Comprehensive Helium Leak Testing Systems

Explore our range of advanced helium testing solutions, from high-sensitivity vacuum chambers to cost-effective accumulation systems designed to meet the strictest industry standards.

Whether you're leak testing fuel tanks, HVAC parts, or medical devices, our technologies include hard vacuum systems, cost-effective accumulation testing, pinpoint sniff detection, and strategic spray methods. Each tailored for precision and reliability.

Cost-effective and chamber-free, accumulation testing uses helium as a tracer gas under atmospheric pressure. Ideal for detecting medium-to-small leaks with repeatable accuracy, it's a perfect upgrade from air-under-water and pressure decay methods.

Best for large or complex parts, sniff testing locates helium leaks directly using a handheld or robot arm-held probe. It's ideal when pinpointing and repairing leaks is essential — especially when full chamber testing isn't practical.

Designed for evacuated parts, helium spray testing strategically exposes components to helium to detect areas of potential ingress. A reliable choice for parts requiring absolute barrier integrity under vacuum conditions.

Frequently Asked Questions

Find quick answers to common questions about our helium leak testing systems, methods, and applications.

Speak to a Helium Leak Testing Specialist

Get personalised guidance for your leak testing challenges.