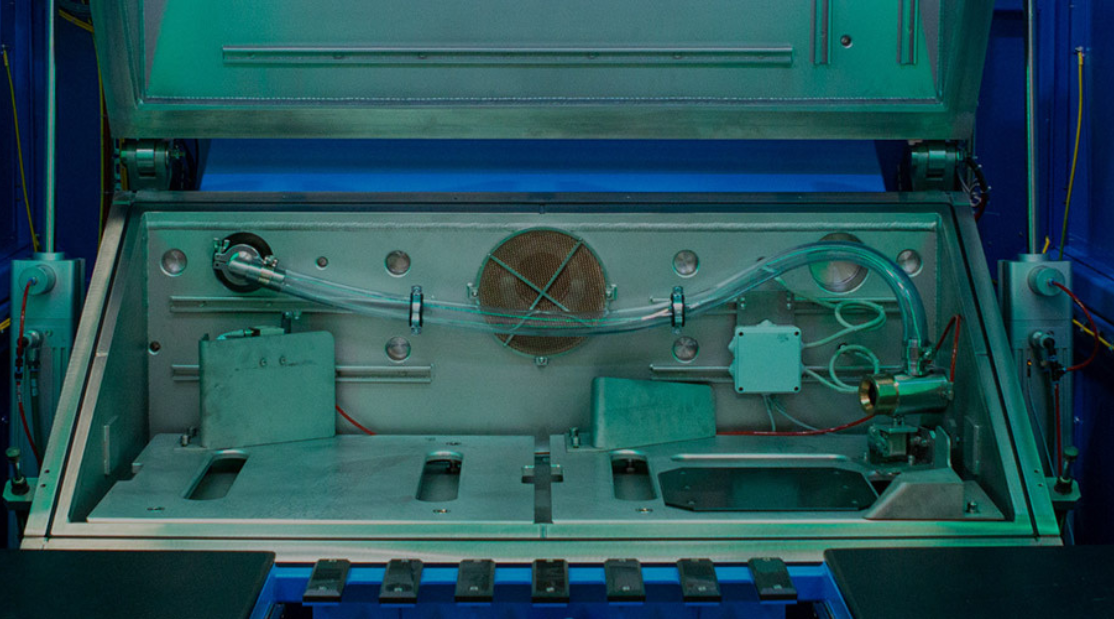

We recently dispatched a new twin-chamber leak testing system from our Trafford Park facility in Manchester. This innovative system will allow automotive manufacturers to conduct accurate helium leak testing on fuel tanks. This highly efficient leak-testing machine has been designed and manufactured with a front-loading configuration and automated vertical sliding door. It is optimised for a single operator to test cutting-edge automotive fuel tanks at a rate of up to 65 units per hour. Pass/fail criteria can be tailored based on each customer’s needs.

To enable easy and safe operation, we included an arm-mounted HMI display screen, product feed table, and safety light curtain. Automated tank couplings adjust to fit different fuel tank variations. A barcode scanner provides product traceability.

Our engineering team developed a unique nitrogen purge system that boosts the performance of the pumping system. This stabilises chamber pressure for reliable, exceptional helium leak testing with a high tolerance for helium background.

The large twin vacuum chambers are adaptable to test future fuel tank models on the same system. This flexibility allows automotive manufacturers to streamline validation as new models are launched.

With decades of experience engineering custom leak testing solutions, our skilled sales engineers can consult on implementing helium leak testing processes and equipment.

For assistance with our advanced leak detection systems and customised solutions, contact us for more information.