Leak Testing Battery Cells

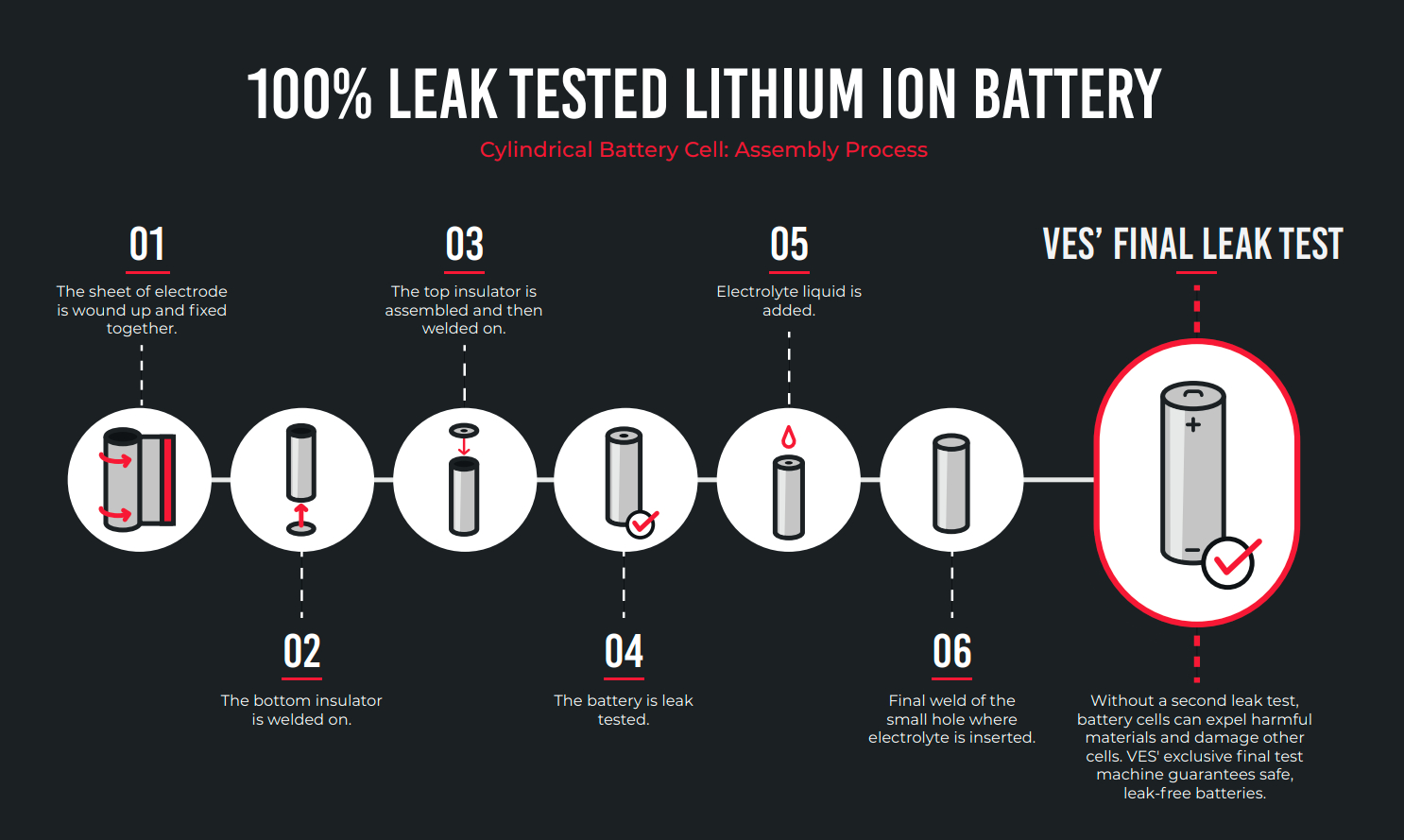

As leak testing experts, VES know the importance of testing battery cells to a high standard before they enter the market.

However, most battery cell leak testers can only be used partway through the production process, before the lithium-ion liquid is added. This leaves you and your customers vulnerable to leaks caused later in the process, for example during the final weld of the battery cell.

That’s why we created CellCheck, our end-of-line battery cell leak detection machine designed specifically for leak testing battery cells. The only machine on the market that tests the finished product, CellCheck is the only leak tester that can guarantee leak-tight batteries.

Want to know more about CellCheck? Sign up below for more information