Helium leak testing is an essential step in many manufacturing processes, ensuring that products meet the necessary standards of quality and safety.

However, choosing the right helium leak testing machine for your manufacturing needs can be a daunting task.

There are various factors to consider, such as the type of product being tested, the required sensitivity level, and the desired throughput.

At VES, we have over 25 years of experience in providing leak testing solutions for various industries. In this article, we will provide a guide to help you choose the right helium leak testing machine for your manufacturing needs.

Considerations When Choosing a Helium Leak Testing Machine

- Type of Product Being Tested: The type of product being tested is a critical factor in choosing a helium leak testing machine. The size, shape, and material of the product will affect the type of testing method used, as well as the required sensitivity level.

- Required Sensitivity Level: The sensitivity level required for leak testing will depend on the application. For example, medical devices and aerospace components require high levels of sensitivity, while other applications may require lower sensitivity levels.

- Throughput: The required throughput of the leak testing machine will depend on the manufacturing process. High-volume production may require a machine with a higher throughput, while low-volume production may require a machine with a lower throughput.

- Budget: The budget for the helium leak testing machine is an important consideration. Machines with higher sensitivity levels and higher throughputs will typically cost more.

Types of Helium Leak Testing Machines

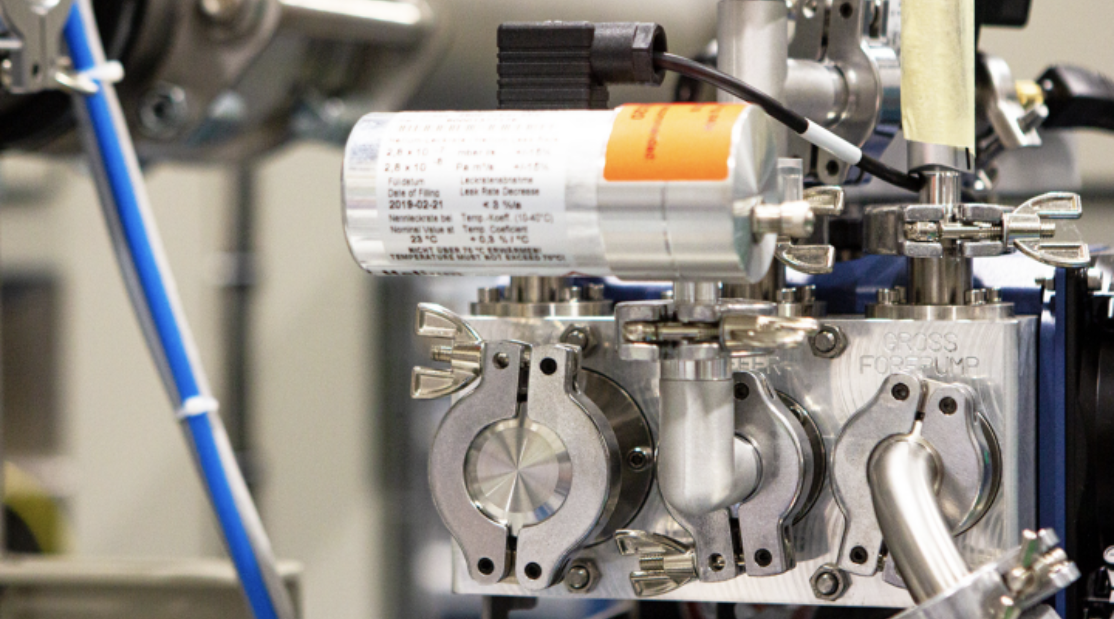

- Hard Vacuum Testing: This type of testing uses a vacuum chamber to isolate the product being tested. Helium is then introduced into the chamber, and any leaks are detected using a mass spectrometer. Hard vacuum testing is ideal for small to medium-sized products and can achieve high sensitivity levels.

- Accumulation Testing: This type of testing uses a closed system and continuously introduces helium gas into the system. Any leaks will cause a concentration of helium gas to accumulate, which is then detected using a helium leak detector. Accumulation testing is ideal for testing larger products and can achieve high sensitivity levels.

- Sniff Testing: This type of testing uses a helium leak detector to directly sniff out any leaks in the product being tested. Sniff testing is ideal for testing products with complex geometries and can achieve high sensitivity levels.

Choosing the Right Helium Leak Testing Machine for Your Manufacturing Needs

When choosing a helium leak testing machine, it is important to consider the specific needs and requirements of your manufacturing process. Factors such as the type of product being tested, required sensitivity level, and desired throughput will all affect the choice of machine.

At VES, we offer a range of helium leak testing machines that can be customised to meet your specific manufacturing needs. Our machines are designed to provide accurate and reliable leak testing while maximising efficiency and reducing costs. With over 25 years of experience in providing leak testing solutions, we are confident that we can help you choose the right machine for your manufacturing needs.