In industries requiring airtight manufacturing standards, leak testing is essential to ensure product quality, safety, and compliance. Whether it’s aerospace components, medical devices, or automotive parts, leak detection directly affects the reliability and durability of finished products. Of the many methods available for leak detection, helium leak testing has emerged as a leading option, recognised for its high sensitivity and reliability. However, as with any technique, it comes with specific considerations related to cost and efficiency. Here, we explore helium leak testing compared to other prevalent methods to help manufacturers make informed choices.

Understanding Helium Leak Testing

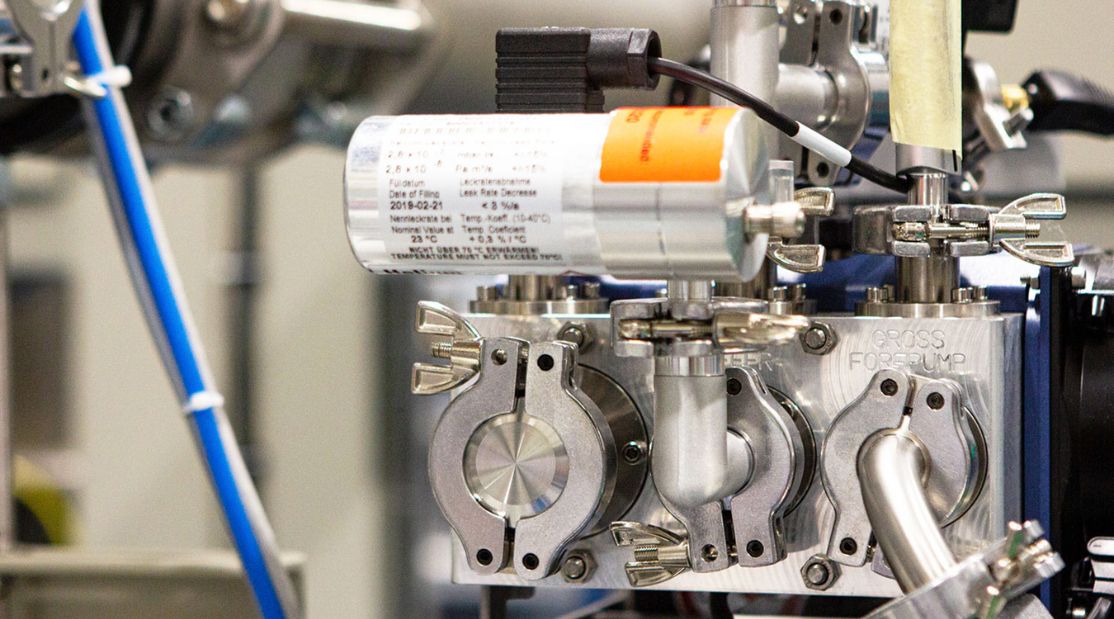

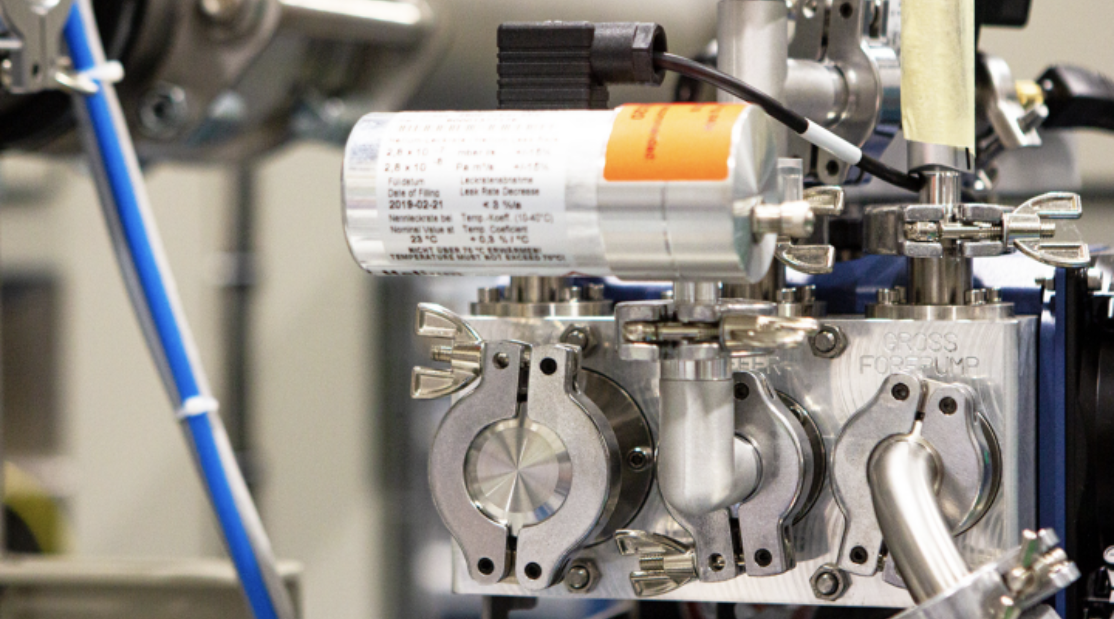

Helium leak testing is a form of tracer gas detection that involves filling a test object with helium and monitoring for leaks using a mass spectrometer or other sensitive equipment. Because helium is inert, non-toxic, and not naturally present in high concentrations in the atmosphere, it is ideal for finding even minute leaks. Its primary advantage lies in its precision and sensitivity, capable of detecting leaks as small as 10^-12 mbar∙L/s.

Cost and Efficiency Benefits

- Sensitivity: Helium’s high sensitivity means that leaks are detected and located quickly. This is required in applications like medical devices or aerospace parts where undetected leaks could lead to product failure or safety risks.

- Versatility: The same helium testing equipment can be configured for various leak detection modes (e.g., sniffer or vacuum mode), allowing manufacturers to use it for different applications.

- Reduced Downtime: Rapidly identifying leak sources means repairs can be made promptly, reducing production delays and the associated costs.

- Long-Term Savings: Though initial setup costs can be higher, the precision and reliability of helium leak testing can lead to lower long-term operational costs by reducing the need for costly repairs and recalls.

Comparing Alternative Leak Testing Methods

- Bubble Testing: This traditional method involves submerging a pressurised object in water or applying a soap solution to its surface and observing for bubbles. While cost-effective for larger leaks, it’s unsuitable for detecting very small leaks and can be time-consuming for intricate components.

- Pressure Decay Testing: In this method, a pressurised object is monitored for a loss in pressure over time, indicating a leak. While simpler and relatively inexpensive, it’s less sensitive than helium testing, particularly for smaller leaks, and requires stable ambient conditions for accurate results.

- Mass Flow Testing: Mass flow sensors measure the rate of gas flow through a system to detect leaks. This method is sensitive to larger leaks but can struggle to detect smaller ones, and its calibration can be affected by temperature and humidity changes.

- Hydrogen Leak Testing: Like helium testing, hydrogen uses tracer gas detection but employs a mix of hydrogen and nitrogen as the test gas. Although sensitive and cost-effective, hydrogen is flammable and requires strict safety protocols.

Key Considerations in Method Selection

- Application Requirements: The sensitivity requirements vary greatly depending on the industry. Medical devices and aerospace components demand high-precision leak detection, where helium testing excels.

- Safety and Environmental Concerns: Hydrogen testing requires careful safety protocols due to flammability, while helium testing is safe but can be expensive if leaks are frequent.

- Production Scale and Cost: While helium leak testing often involves a higher upfront cost, it provides savings over time by reducing false positives and improving quality control.

- Flexibility and Adaptability: Manufacturers dealing with multiple types of products may benefit from the versatility of helium testing equipment, as it can often be adapted for various applications.

Why Helium Leak Testing Remains the Premier Choice

Helium leak testing remains a premier choice for industries where high sensitivity and precision are important. While the method may initially seem more costly, its reliability, flexibility, and ability to identify minute leaks effectively make it a superior option over many alternatives. At VES, we have over 300 years of collective knowledge to develop gold-standard helium leak test equipment for a diverse range of applications. With customer-centric technical support and innovative engineering, we continue to ensure that our clients receive unparalleled service, helping them navigate the complexities of leak testing with confidence.