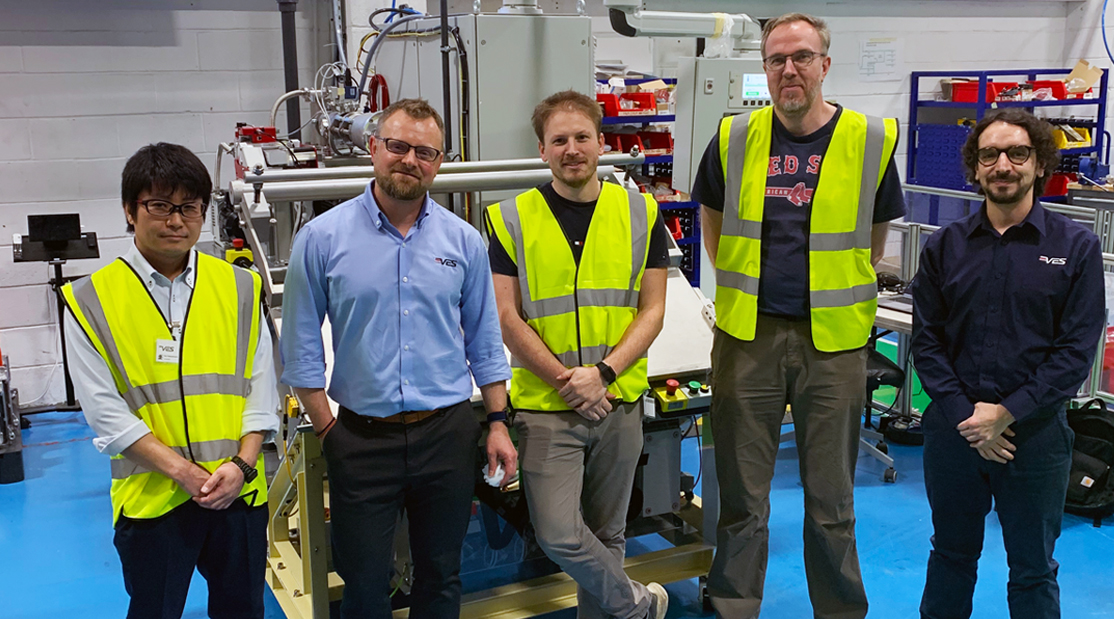

Our vastly experienced Eastern European Sales Manager Jiri Pechacek (blue shirt) recently welcomed customers to our Manchester manufacturing facility for some initial leak detection training and witnessing their brand new manually operated single chamber leak detection system in action.

Our engineers run through cycle tests and scenarios with the customer to be able to check and verify all the many aspects of the leak test system’s performance, capabilities and essential safety features.

It’s normally the first time the customer gets hands-on with the finished machine, so we always dedicate lots of time for our customers to get familiar and understand the machine’s components and characteristics, where our multi-disciplined and experienced engineers share their in-depth knowledge.

The hard vacuum leak detection system is designed for testing the leak tightness of the battery housing assembly coolant channel to a specified cycle time and set pass and fail criteria in line with regulations and their production schedule.

The system will be despatched to a car parts manufacturing facility in the Czech Republic, where our engineers will install, commission and provide full operator safety training.

For assistance with our safe, reliable and efficient leak detection systems please contact our sales engineers by email at sales@vac-eng.com.