At our bustling Manchester site, one standout project going through production at the minute is a vacuum helium leak test station. This has been tailored for a leading global manufacturer specialising in heating, cooling, ventilation, air purification, and refrigeration technologies – they offer solutions tailored to every climate need.

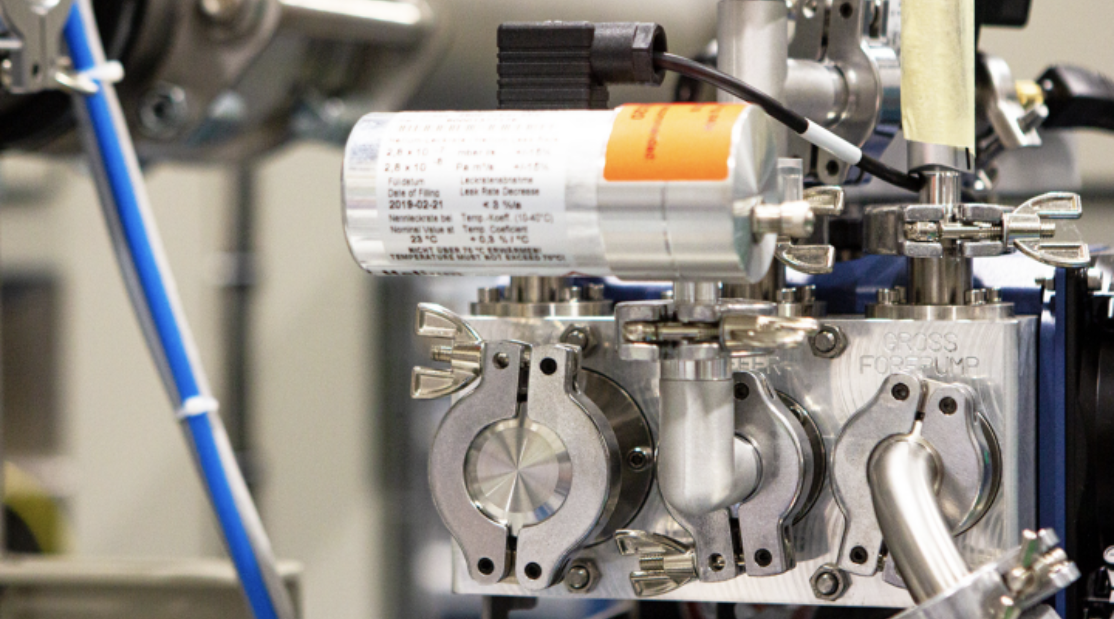

The comprehensive vacuum leak test and detection system is designed to precisely leak test a range of condensing assemblies. The system boasts an automated chamber module, a vacuum pump set/leak detector, an electrical and valve cabinet, and a helium sniffer repair station.

Condenser components are delivered by a production line conveyor to two leak test modules. These components are then automatically loaded and connected, ready for a rigorous pass or fail test cycle. Should a condenser fail, the helium sniffer module swiftly identifies and isolates faulty parts, ensuring swift repairs and retests, thereby optimising productivity.

Our team of vacuum system and leak detection specialists collaborated closely with our client to deliver an energy-efficient condenser testing solution. After the leak test system passes its customer-witnessed factory acceptance test, it will be shipped. Following this, our engineers will oversee its installation and commissioning. They’ll also provide comprehensive on-site safety and operator training.

Please contact us for more information on our advanced HVAC leak detection systems and bespoke solutions.