At VES, we’ve built our reputation on understanding the demands of helium leak testing—a process that ensures the integrity and safety of products across a variety of industries. With our innovation, the PURE Helium Recovery System, we continue to lead the market by offering a solution that not only addresses the global helium shortage but does so with an unprecedented ease of integration for manufacturers.

Streamlined Setup

One of the areas that our PURE system excels in the helium recovery market is its plug-and-play design. This feature allows for rapid integration into existing production lines without significant disruption. Traditional systems often require extensive downtime for installation, calibration, and testing. In contrast, PURE’s design is predicated on ease and efficiency, enabling it to be set up and operational in a fraction of the time usually required.

This swift integration process begins with PURE’s compact and mobile design. The system can be easily moved and connected to various points within a production environment, eliminating the need for permanent installation spaces or extensive retrofitting. This mobility is a game-changer for facilities that operate on tight production schedules and cannot afford lengthy interruptions.

Immediate Operational Benefits

The benefits of implementing PURE are immediate. Once connected, the system begins recovering and purifying helium from leak testing operations at efficiencies previously unseen. The ability to recover helium at the required purity specification not only conserves an expensive and limited resource but also significantly reduces operational costs. For many manufacturers, the cost savings are evident within just a few months, making PURE an investment that quickly pays for itself.

Also, PURE’s effectiveness isn’t limited by the scale of the operation. Whether it’s a small batch production or a high volume line, the system’s adaptability allows it to function efficiently across different settings. Its compatibility with any helium leak testing (HeLT) equipment operating below 3 bar pressure makes it a versatile solution suitable for a wide range of industries—from automotive and aerospace to electronics and pharmaceuticals.

No Compromise on Testing Integrity

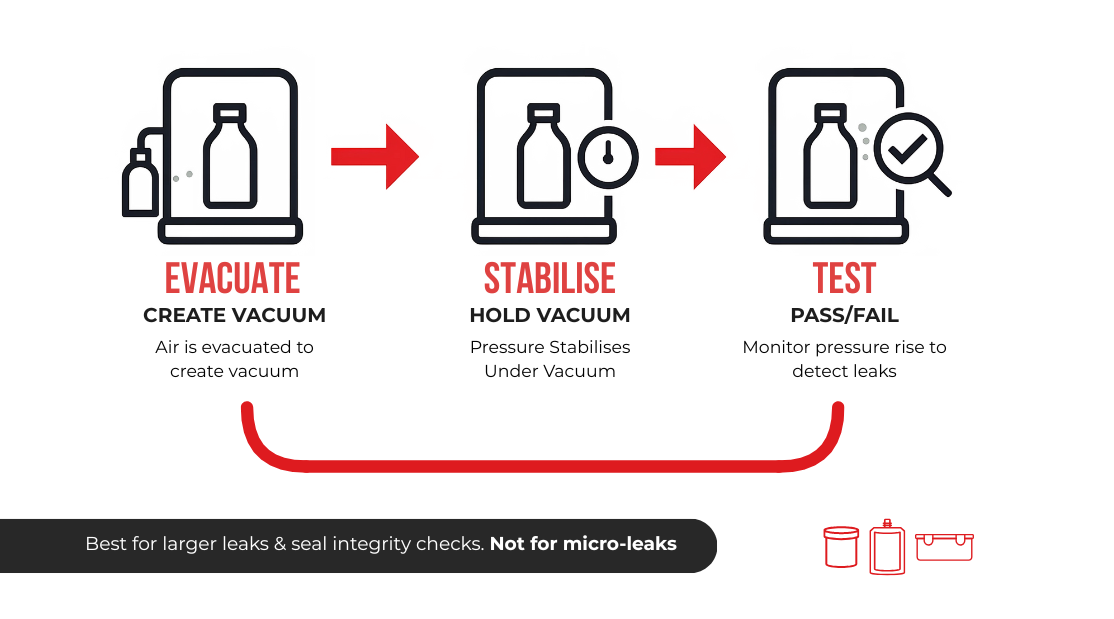

One of the significant advantages of the PURE system is its ability to maintain the integrity of the helium used in testing. Even when recycling helium from tests, PURE ensures that the gas meets or exceeds the original purity specifications required for accurate and reliable leak detection. This feature is required, as even minor deviations in helium quality can lead to compromised test results and potentially undetected leaks.

Additionally, PURE’s technology is designed to handle helium-air or helium-nitrogen mixtures at concentrations as low as 70%, purifying them back to the required concentrations for reuse in testing processes. This capability is particularly beneficial in applications with low leak rates, where maintaining high purity and pressure is essential.

Adapting Without Disruption

Unlike other systems that may require adjustments to the pre-evacuation levels of the machines they’re paired with, PURE does not necessitate such modifications. This means that existing leak testing cycles do not need to be altered to accommodate the recovery system, ensuring that production efficiency is maintained without compromising test quality or throughput.

Looking Forward

As industries continue to face pressures both economically and environmentally, solutions like PURE represent a step forward in operational efficiency and sustainability. By reducing helium waste and lowering the dependency on helium sourcing, companies can better manage their resources while contributing to broader environmental goals.

The PURE Helium Recovery System provides a seamless, efficient, and effective solution to one of the industry’s most pressing challenges. With over 300 years of combined expertise in helium leak testing, VES are proud to offer a product that not only meets the high standards of today’s market but also sets new benchmarks for performance and sustainability in the industry.

As we continue to support and innovate within the helium leak testing field, we remain focused on delivering gold-star systems that ensure our customers’ operations are as successful and sustainable as possible.