As renewable energy continues to gain popularity and importance in the world, the role of battery cell quality assurance in ensuring the safety and reliability of these energy storage systems has become increasingly vital. Battery cells are the backbone of renewable energy storage, and their performance directly affects the efficiency and reliability of the entire system.

Battery cells are a critical component of renewable energy storage systems, as they store the energy produced by solar panels or wind turbines for use when the demand for energy is high or when the energy source is not available. However, a poorly designed or faulty battery cell can cause serious problems, such as overheating, combustion, and even explosions. That is why battery cell quality assurance is essential to ensuring the safety and reliability of these systems.

There are several factors that can affect the quality of battery cells, including the manufacturing process, the materials used, and the design of the battery cell itself. It is crucial that battery manufacturers carefully consider all of these factors and implement rigorous quality assurance procedures to ensure that their products are safe and reliable.

One of the most important aspects of battery cell quality assurance is leak testing. Battery cell leaks are often caused by manufacturing mistakes that were missed during the quality assurance process and can cause significant damage to health, other battery cells, and the manufacturer’s reputation. A leaking battery cell can cause serious problems, including the release of dangerous substances such as hydrofluoric acid, which can be harmful to human health and the environment.

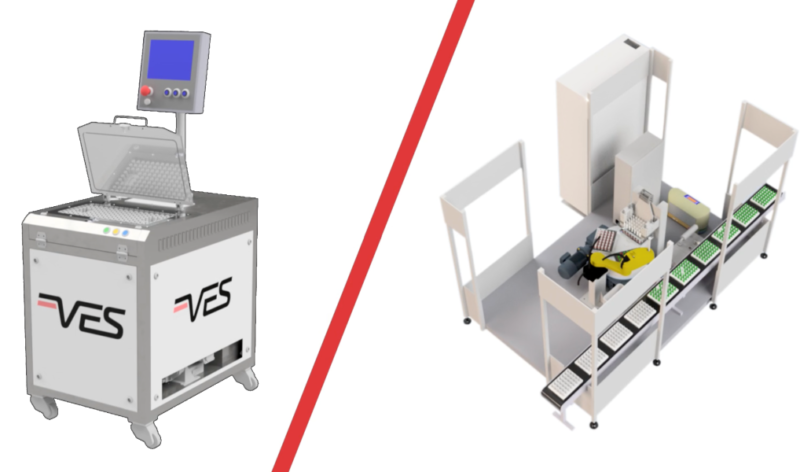

That is why leak testing is so important in the battery cell industry. By using a high-quality leak detection machine like CellCheck, battery manufacturers can ensure that their products are leak-tight and safe for use in renewable energy storage systems. CellCheck is the only machine on the market that tests the finished product after the final weld, which is when many errors occur, which means that it can guarantee leak-tight batteries and provide peace of mind to both manufacturers and end-users.

In addition to leak testing, there are other quality assurance measures that battery manufacturers can implement to ensure the safety and reliability of their products. For example, they can use high-quality materials that are resistant to wear and tear, implement strict manufacturing processes that minimize the risk of defects, and regularly test their products to ensure that they meet industry standards and regulations.

It is also important for battery manufacturers to stay up-to-date with the latest developments in battery cell technology and to continually innovate and improve their products. The renewable energy industry is constantly evolving, and battery manufacturers must be able to adapt to new technologies and changing market conditions in order to remain competitive and provide the best possible products to their customers.

The role of battery cell quality assurance in renewable energy is critical to ensuring the safety and reliability of these systems. By implementing rigorous quality assurance procedures, such as leak testing and using high-quality materials, battery manufacturers can provide peace of mind to both themselves and their customers. With the help of innovative technologies like CellCheck, we can continue to improve the quality of battery cells and drive the growth of the renewable energy industry forward.