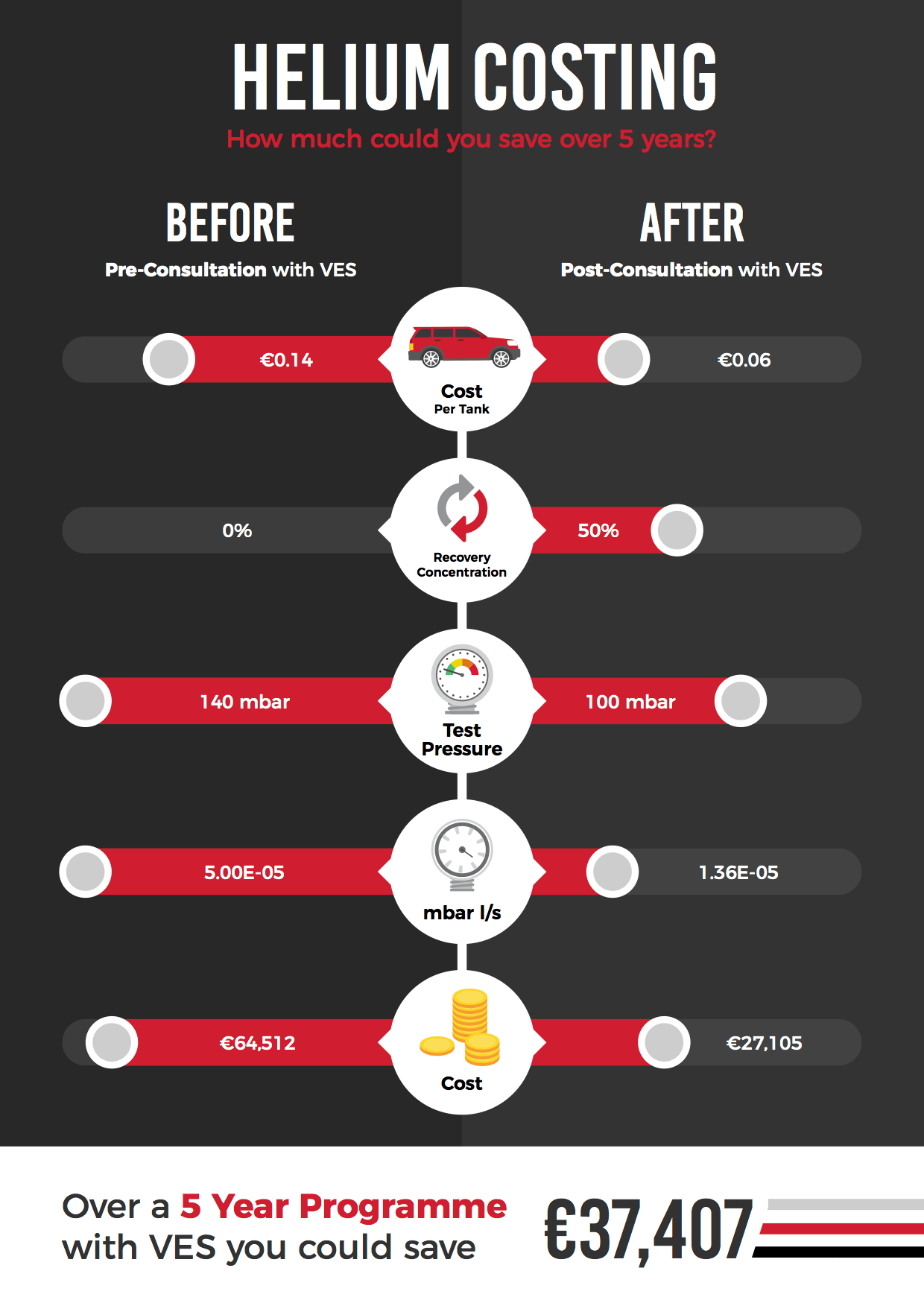

As Helium Shortage 3.0 approaches the end of its second year, companies utilising helium leak test systems are feeling the pinch of rising helium costs on their budget. Fortunately, at VES, we have identified a few short-term measures to save helium without sacrificing performance.

As Helium Shortage 3.0 approaches the end of its second year, companies utilising helium leak test systems are feeling the pinch of rising helium costs on their budget. Fortunately, at VES, we have identified a few short-term measures to save helium without sacrificing performance.

Helium Consumption Audits

The best way to reduce helium usage in the future is to assess how you already use helium. Companies invest huge amounts of resource into time and motion assessments of their production lines. However they never do the same type of audit or intervention of helium leak test processes. Optimising your helium leak test process is always a good idea, but is especially worthwhile during a shortage. VES can visit your site to check best practice is being followed, suggest changes and tweaks. We can help you make the most efficient use of your helium. These changes will save you money both in the immediate future and after the shortage has ended.

Helium Extraction

A surprising number of companies are not extracting all of the helium from their bottles. If you’re leaving helium unused, you’re leaving money on the table. Low-cost helium extraction technologies are available to ensure as much helium as possible is being used from each bottle, minimising waste.

Gas Mixer

Depending on your application, it may not be necessary to use 100% helium. Diluting your supply with cheaper gasses, such as nitrogen or dry air, could stretch your helium supply further and save a considerable amount of money. Our gas mixers typically output 10-20% helium concentration, suitable for most leak detection applications. These systems for helium leak testing are fully automated, with no operator required, reducing the cost even further.

Helium Recovery Unit

We’ve covered reducing your helium usage, but did you know you can easily recycle upwards of 80% of your used helium per test? Helium recovery units can reclaim helium from a test, and recompress it to the required pressure needed for use in another test. This is another system that does not require an operator. Once the machine is set up you can simply collect the saved helium and reuse it, saving helium and vastly reducing helium costs. You can find out more about VES’ helium recovery and repurification system, PURE, here.

It’s always a good idea to optimise your helium usage. It has never been more important than it is now. Helium costs will most likely continue to climb and the best way to keep it from affecting your bottom line is to manage your usage. These methods of reducing costs can be assigned to your balance sheet and will have a positive impact on you income statement. Here at VES, we’re committed to saving you money by helping you make the best use of your helium. To find out more about any of these methods and how we can implement them into your business, contact us by phone, email or post.