Our experienced team of dedicated service engineers based in Manchester are always very busy over the summer months with on-site scheduled annual leak test system maintenances, recently at a manufacturing plant producing scroll compressors for residential and commercial heat pumps.

These are regular planned activities our engineers undertake on leak test equipment, to ensure their optimal performance, longevity and safety. Detailed examinations of the equipment checking for wear and tear, damage, or any abnormalities. Removal of dust, debris, or other contaminants that may have accumulated over time, which can affect the performance or safety of the leak test system.

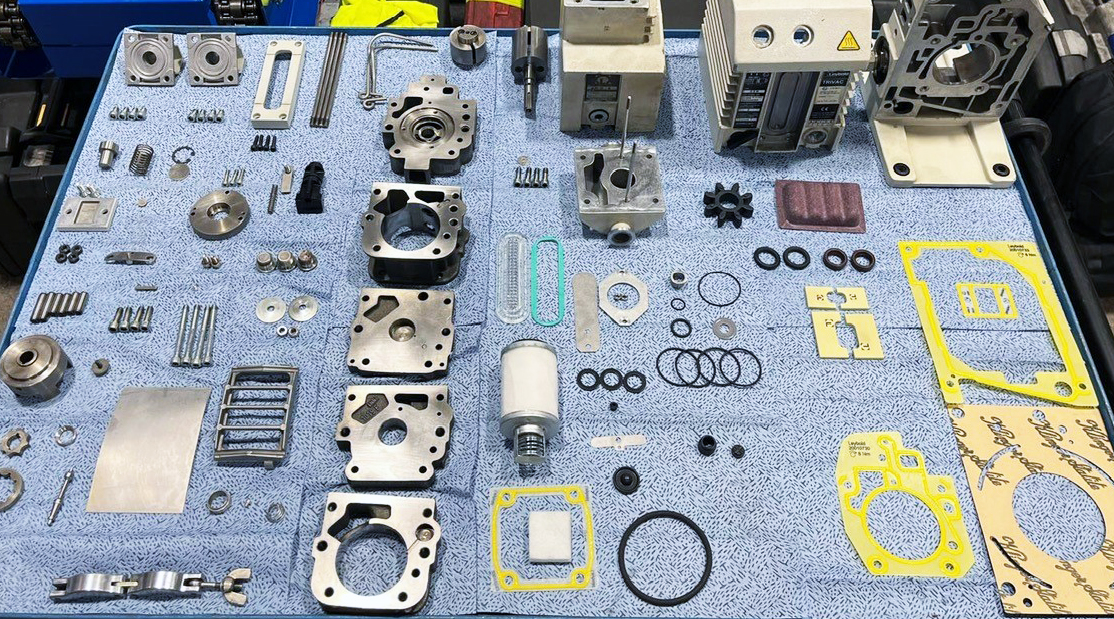

Our engineers thoroughly inspect system components and perform routine maintenance tasks, including stripping down and overhauling the vacuum pumps, changing oil and relubricating, replacing a multitude of seals and filters, along with stripping and cleaning pipework and couplings.

The leak test systems are re-assembled and calibrated including performance tests, safety tests and functionality tests before being released back into operational duties, making sure they run cost-efficiently and operate effectively, using original genuine manufacturer parts and no equivalents.

For assistance with our advanced leak detection systems, along with essential service and maintenance please contact our service engineers by email at service@vac-eng.com, or visit https://vac-eng.com/support for more information.