Tony, one of our team of mechanical engineers is busy building a series of 0-10 bar pressure charge valve panel assemblies.

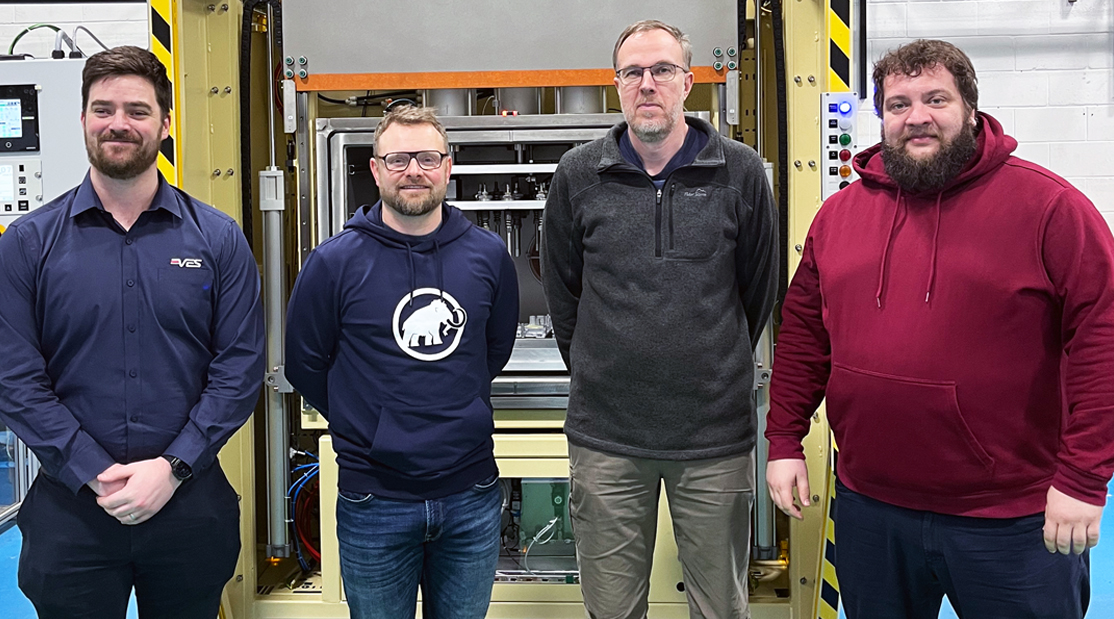

Our skilled engineers are developing a fully automated end-of-line leak detection test cell specifically for testing hollow fibre membrane separators. These separators are crucial for substance separation in diverse industrial processes.

Once operational, the leak detection system will:

- Receive membrane separators manually at the infeed trolley

- Utilize a robot to pick and scan each component

- Automatically place and connect the separator within a helium leak test chamber, initiating the leak test sequence

- Directly pass separators to a drying station via a robot

- Transfer any potentially failed separators to a reject sniffing station for precise leak pinpointing with a helium sniffer probe

- Finally, a robot will move dried separators to the end-of-line for final functionality checks

This automated leak test system provides comprehensive data collection, visualisation, traceability and efficient helium recovery and reuse.

For assistance with our one-stop, single sourced, fully automated end-of-line leak detection solutions designed to reduce production timescales and operating costs – please contact our sales engineers by email at sales@vac-eng.com