Every manufacturer knows: no system is truly leak-free. Tiny imperfections, cracks, porosity, faulty welds, or seals can all lead to leaks. What really matters is knowing how much leakage is acceptable and proving it through quantifiable testing.

Stricter safety and environmental standards demand not just reliable components but verified leak integrity. Whether it’s a hydrogen storage vessel, a fuel cell, or an HVAC system, defining and maintaining a precise maximum leak rate is critical to performance, compliance, and trust.

Understanding Leak Rate (Q)

Leak rate measures gas flow through a defect, expressed as:

Q = V × (Δp / Δt)

Where:

- Q = Leak rate (mbar·L/s)

- V = Volume

- Δp / Δt = Pressure change over time

In simple terms: one mbar·L/s means removing enough gas from a 1 L vessel in one second to reduce its pressure by 1 mbar. This rate depends on pressure differential, gas type, and the geometry of the leak path.

It’s the benchmark for comparing and certifying leak integrity.

Why Helium is the Gold Standard

Helium remains the industry’s preferred tracer gas — and for good reason:

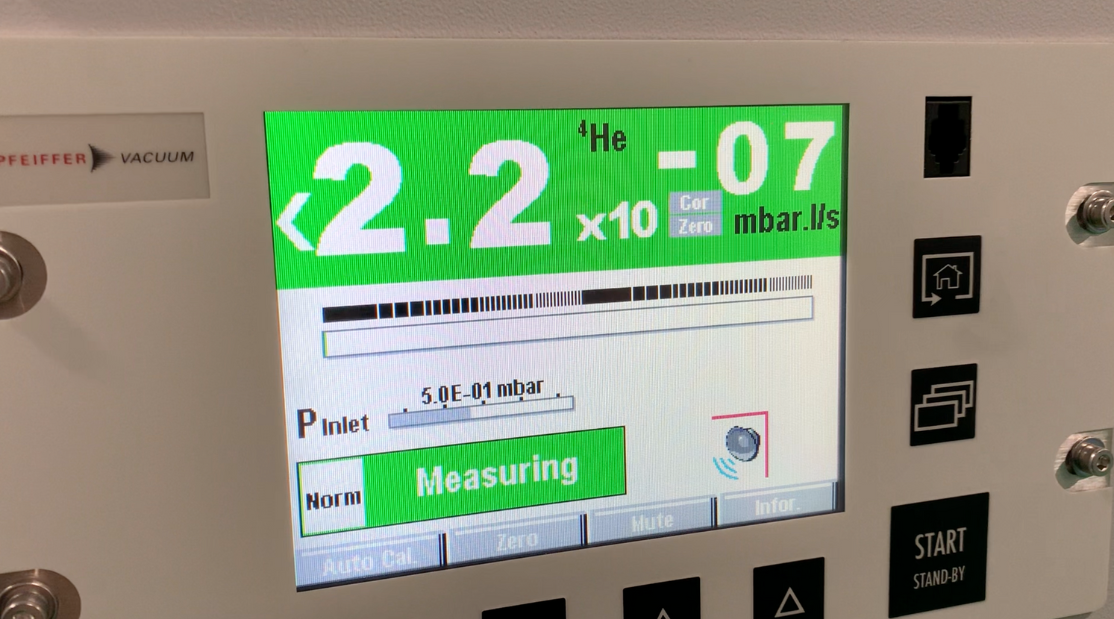

- Exceptional Sensitivity: Detects leaks as small as 1 × 10⁻⁸ mbar·L/s, far beyond what pressure decay or bubble tests can achieve.

- Chemically Inert: Non-reactive, non-flammable, and safe for all materials.

- Distinct and Detectable: Its low background concentration (5.2 ppm) ensures minimal interference.

- Precision Tuned: Its unique atomic mass (4 amu) allows high accuracy via mass spectrometry.

Helium’s reliability and repeatability make it essential for safety-critical applications from hydrogen pressure vessels to battery modules and automotive systems.

Leak Flow Behaviour

Gas flow through a defect occurs in three regimes:

| Flow Regime | Pressure Range (mbar) | Flow Characteristic |

| Viscous / Laminar | 10³ > p > 1 | Orderly flow; governed by Poiseuille’s Law (Q ∝ r⁴) |

| Molecular | 10⁻³ > p > 10⁻⁶ | Molecule-to-wall collisions dominate |

| Transitional | Between both | Hybrid flow regime |

The choice of tracer gas and testing pressure depends on which regime the leak falls into.

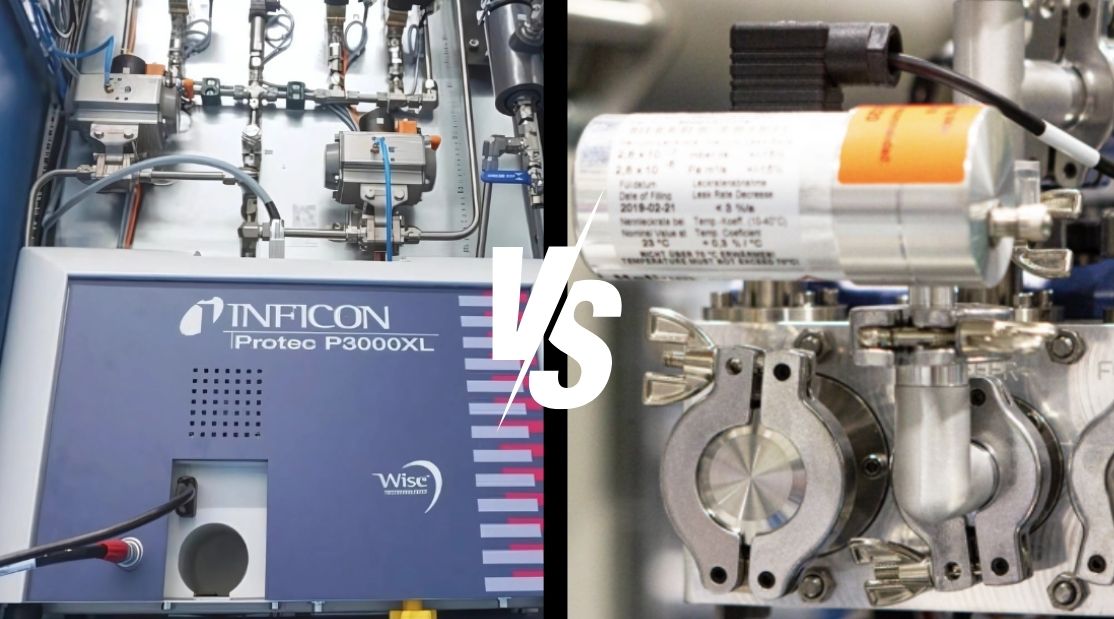

Helium Leak Sniffer Testing – Localised Detection

How It Works

- The component is pressurised with helium.

- A sniffer probe scans welds, joints, or seams.

- A rise in helium concentration indicates a leak.

Key Advantages

- Pinpoint accuracy: Finds the exact leak location.

- High sensitivity: Detects leaks as small as 1 × 10⁻⁶ mbar·L/s.

- Cost-effective: Compact, dry system without vacuum chambers.

Limitations

- Operator dependent: Accuracy varies with probe control.

- Lower throughput: Manual process limits speed.

- Local only: Doesn’t provide total leakage rate.

- Safety risks: High-pressure tests require care.

Sniffer testing is ideal for diagnostics, repair, and small-scale testing — where localisation matters more than volume throughput.

Helium Accumulation Testing – Integral Detection

How It Works

- The part is placed inside a sealed chamber.

- After evacuation, it’s pressurised with helium.

- Fans circulate gas for uniform detection.

- The system measures total helium concentration increase to calculate overall leak rate.

Key Advantages

- Operator independent: Fully repeatable and automated.

- Efficient throughput: Suitable for production lines.

- Highly sensitive: Down to 1 × 10⁻³ mbar·L/s, depending on chamber size.

- Versatile and stable: Works even with warm or freshly brazed parts.

- Sustainable: Compatible with forming gas or helium recovery systems, reducing operating costs by up to 94%.

Limitations

- Cannot pinpoint leak locations directly (but a sniffer probe can be added for confirmation).

Accumulation testing provides a complete, quantifiable picture of component integrity, perfect for hydrogen tanks, fuel cells, and battery modules.

Comparison at a Glance

| Feature | Sniffer | Accumulation |

| Detection Type | Point / Local | Total / Integral |

| Typical Sensitivity | 1 × 10⁻⁶ mbar·L/s | 1 × 10⁻³ mbar·L/s |

| Leak Location | Yes | No |

| Throughput | Low | High |

| Reliability | Operator-dependent | Automated, repeatable |

| System Cost | Low | Moderate |

| Ideal Use | Leak pinpointing and rework | Production testing and quality assurance |

Choosing the Right Method

Your choice depends on application and production goals:

- For pinpointing leaks: Sniffer testing offers accuracy and flexibility.

- For production validation: Accumulation testing ensures consistency, scalability, and compliance.

- For extreme sensitivity: Combine both; accumulation for overall integrity, sniffer for fault isolation.

At Vacuum Engineering Services we integrate both approaches into modular systems tailored to your needs, whether it’s testing 900 bar hydrogen tanks, fuel cells, or refrigerant systems.

Each VES solution ensures precision, repeatability, and safety, backed by decades of expertise and over 1,600 installations worldwide

The Bottom Line

Both methods have their place in modern manufacturing. Helium leak sniffer testing helps you find the fault. Accumulation testing helps you prove compliance.

VES designs and builds both, from compact sniffer units to fully automated accumulation systems, giving manufacturers in automotive, hydrogen, HVAC, and clean energy sectors the confidence that every product meets global safety and performance standards.

Accurate. Scalable. Sustainable.

That’s the VES standard in leak testing.