Leak testing is often misunderstood, even by experienced engineers and manufacturers. Despite improvements in technology, outdated assumptions still guide decisions. One of the most common is the idea that if a part holds pressure, it must not be leaking. This belief seems logical at first, but can result in serious issues, from product failures to safety risks and costly rework.

The Problem with Holding Pressure

On the surface, a part that holds pressure seems like a sealed and reliable product. But pressure hold or pressure decay tests often cannot detect very small leaks. These methods rely on measuring changes in pressure over time. If the leak is slow enough, it will not show up, and that can create serious risks.

In applications like hydrogen pressure vessels, even the smallest leak can compromise safety, lead to regulatory failures, or cause expensive field issues. Hydrogen molecules are extremely small. They move quickly and can escape through the tiniest of openings. Relying only on a pressure hold test means taking a gamble on leak integrity.

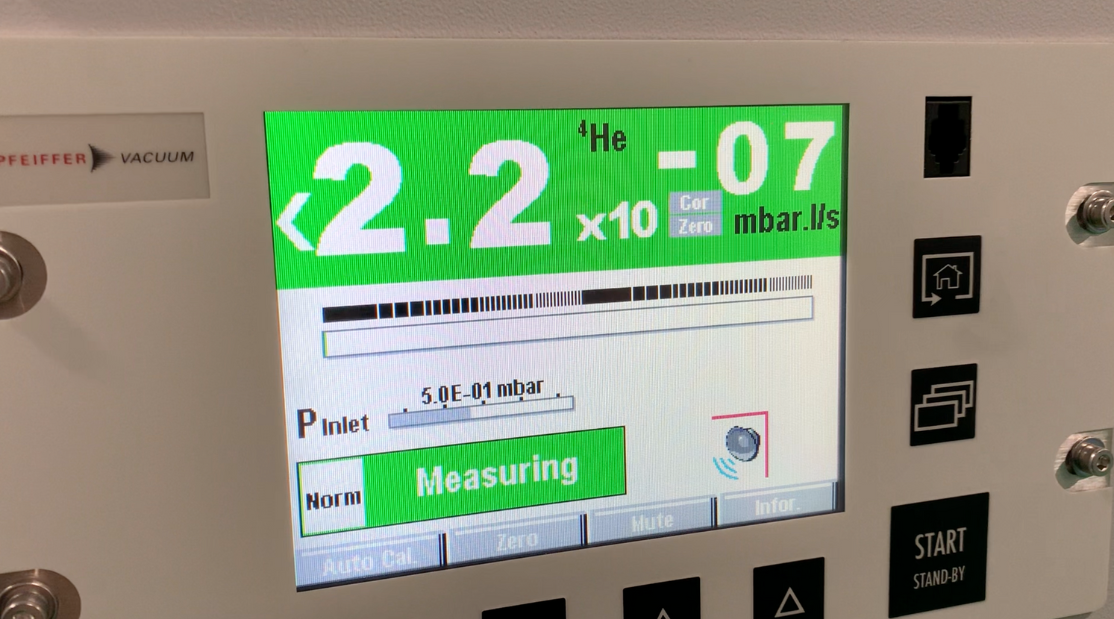

This is why many leading manufacturers now prefer more sensitive techniques such as helium or forming gas testing. These methods can detect micro leaks that traditional pressure-based tests would miss. They also help meet global safety standards like R134 and TCATSI.

Is Helium Leak Testing Worth It?

A common belief is that helium testing is too expensive. While helium is not cheap, assuming it is not worth the investment misses the bigger picture.

The real question is not about the cost of helium itself, but how efficiently it is used.

We created PURE, a helium recovery and purification system that captures and reuses helium from each test cycle. This significantly cuts down on helium consumption and operating costs. In some cases, the savings reach over 90%. When testing large volumes, the return on investment becomes clear very quickly.

So, is helium testing expensive? Not when it is implemented the right way. It becomes one of the most efficient ways to achieve accurate and repeatable results without sacrificing performance.

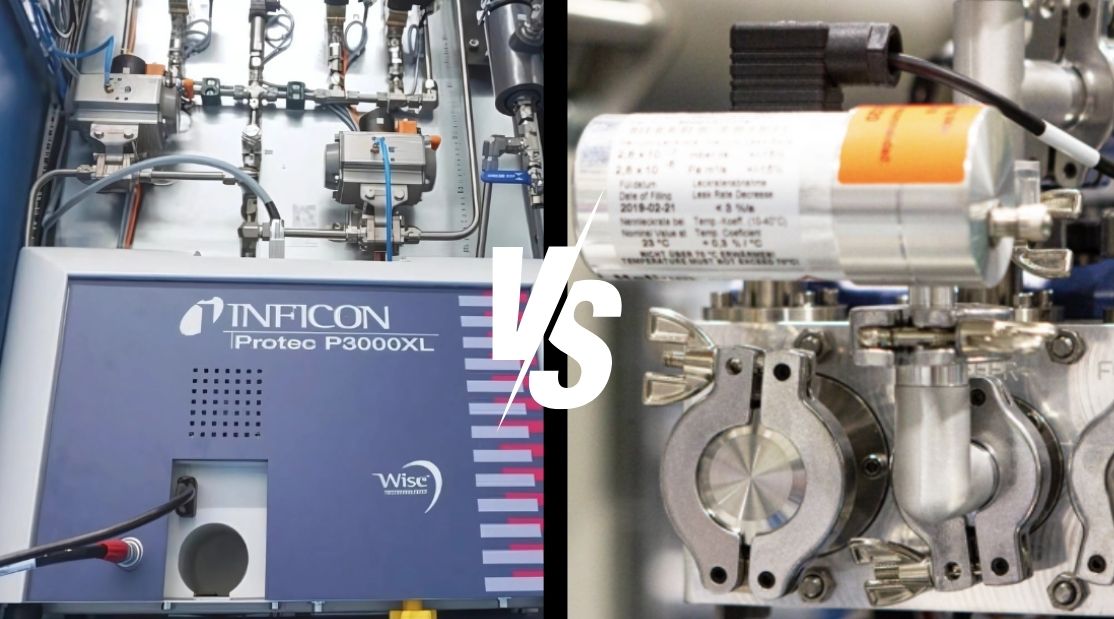

Not All Leak Tests Are the Same

Another widespread misconception is that all leak tests are interchangeable. The reality is that different products and applications require different approaches. Pressure decay works well in some scenarios. Accumulation testing is better suited for others. Sniff and spray testing are ideal when identifying the exact location of a leak is important. In high-performance environments like hydrogen storage or fuel cell production, hard vacuum helium testing is often the preferred option.

Choosing the right method is not just a technical decision. It affects the reliability of your results, your compliance with standards, and the efficiency of your production line.

That is why we build systems that are flexible and modular. Whether you are testing refrigerant coils, air suspension systems, or high-pressure hydrogen tanks, your equipment should be accurate, efficient, and tailored to your production needs. A one-size-fits-all approach is never the best solution.

Moving Past the Myths

When leak testing is treated as an afterthought, the consequences can be severe. Product failures, safety issues, and non-compliance are all risks that can be avoided with the right approach.

The good news is that better options are available. You do not have to settle for outdated methods or make a trade-off between cost and quality. You can have reliable results, consistent performance, and full compliance with modern safety standards.

At VES, we work with manufacturers to replace myths with proven methods. Our goal is to provide smarter systems, tailored solutions, and ongoing support that help you stay ahead of the curve in leak detection.