The role of hydrogen as a clean energy source brings with it the need for robust safety measures in hydrogen storage. Advanced leak detection technologies are essential in ensuring that hydrogen storage vessels operate safely and reliably under high pressure. In this article, we will look into the latest innovations in leak detection, showcasing how our New Energies’ SIL-rated OTV temperature monitoring circuits provide exceptional precision in leak detection.

The Importance of Leak Detection in Hydrogen Storage

Hydrogen, being highly flammable and under high pressure, poses significant safety risks if not properly contained. Effective leak detection is required to prevent accidents and ensure the safe operation of hydrogen storage systems. Advanced leak detection technologies enable manufacturers to detect and address leaks promptly, safeguarding both the environment and human lives.

Advanced Leak Detection Technologies

The following are some of the leak detection technologies that ensure the safety and reliability of hydrogen storage vessels:

1. Helium Leak Detection

Helium leak detection is renowned for its sensitivity and accuracy. Helium, due to its small atomic size, can easily penetrate even the smallest leaks, making it an ideal tracer gas. We employ helium leak detection to provide precise and reliable identification of leaks in hydrogen storage vessels.

2. Hydrogen Sniffing

Hydrogen sniffing involves using sensors to detect hydrogen in the air around the storage vessel. These sensors are highly sensitive and can detect low concentrations of hydrogen, allowing for early leak detection. This method is particularly useful for continuous monitoring and ensuring the safety of storage systems.

3. Pressure Decay Testing

Pressure decay testing measures the rate at which pressure decreases in a sealed vessel. A faster pressure drop indicates a leak. This method is effective for detecting larger leaks and is often used in conjunction with other technologies for a comprehensive leak detection approach.

4. Vacuum Decay Testing

Similar to pressure decay testing, vacuum decay testing measures the rate at which a vacuum is lost in a sealed vessel. This method is highly effective for detecting small leaks and is widely used in the manufacturing of hydrogen storage vessels to ensure their integrity.

Leading the Way in Leak Detection

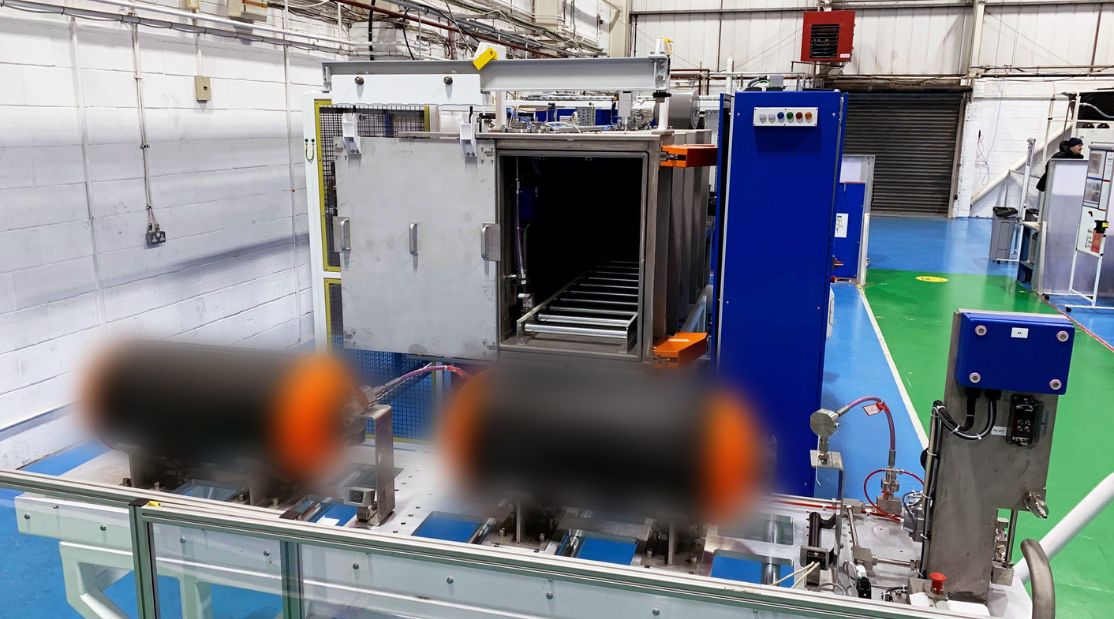

At VES, we are dedicated to developing advanced leak detection technologies to ensure the highest safety standards in hydrogen storage. Our system is designed to meet and exceed international standards, providing our customers with reliable and compliant solutions.

SIL-rated OTV Temperature Monitoring Circuits

A standout feature of the New Energies system is our Safety Integrity Level (SIL)-rated Over-Temperature Valve (OTV) temperature monitoring circuits. These circuits are essential in enhancing the safety and reliability of hydrogen storage systems by providing precise leak detection.

How SIL-rated OTV Circuits Work

The SIL rating measures a system’s performance in terms of its likelihood to perform a safety function under specified conditions. Our SIL-rated OTV temperature monitoring circuits detect abnormal temperature changes that could indicate a leak. Integrated into the storage vessel, these circuits continuously monitor temperature, ensuring any deviation from normal is detected and addressed promptly.

Benefits of SIL-rated OTV Circuits

- Enhanced Safety: Real-time temperature monitoring ensures early detection of potential leaks, preventing hazardous situations.

- High Precision: The circuits are highly sensitive to even the smallest temperature changes, ensuring precise leak detection.

- Regulatory Compliance: Our SIL-rated OTV circuits meet stringent international standards, providing assurance that hydrogen storage systems are compliant with global safety regulations.

Comprehensive Leak Detection Solutions

In addition to our SIL-rated OTV temperature monitoring circuits, our system incorporates a range of advanced leak detection technologies to ensure comprehensive safety and reliability.

Traceable Calibrated Leaks

Using traceable calibrated leaks, our system ensures the accuracy and repeatability of the leak detection process. This feature provides an added layer of assurance, verifying that the leak detection methods are performing to the highest standards.

Compliance with Pressure Regulations

Compliance with pressure regulations is critical in maintaining the integrity of hydrogen storage vessels. Our system is designed to test vessels at pressures ranging from 350 to 875 bar, ensuring they can withstand the operational stresses they will face.

Conclusion

As the hydrogen energy sector continues to expand, the need for advanced leak detection technologies becomes essential. Our SIL-rated OTV temperature monitoring circuits, combined with our modular design, traceable calibrated leaks, and compliance with international standards, make our system a leader in leak detection technology. By prioritising safety and precision, we are helping to drive the hydrogen energy sector towards a safer and more sustainable future.