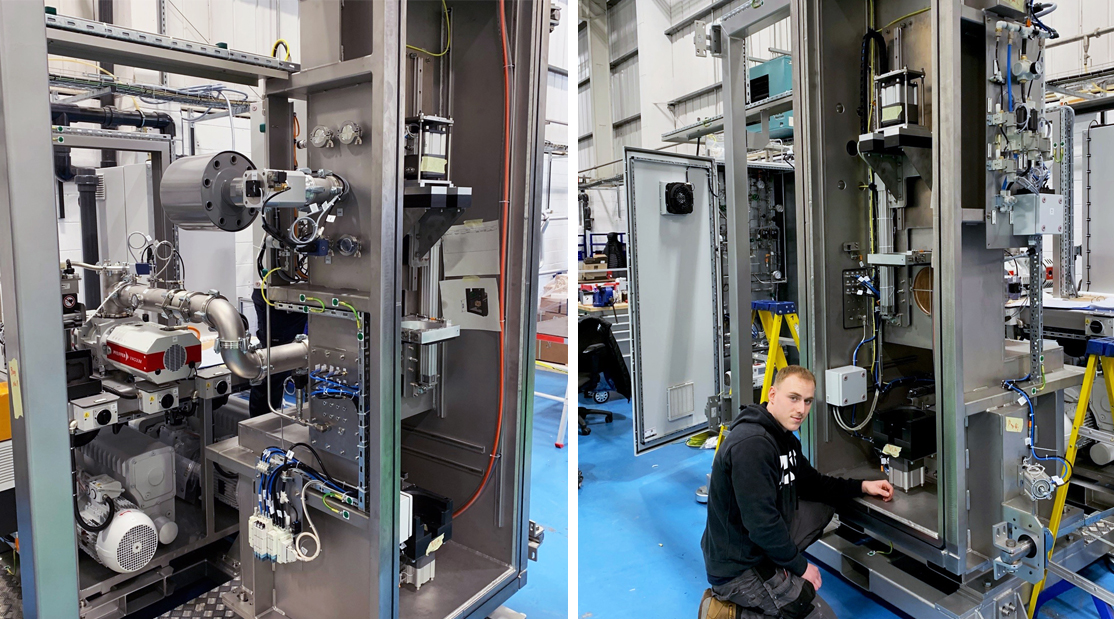

Our knowledgeable engineers are producing a fully automated end-of-line leak detection process cell being built for leak testing hollow fibre membrane separators, which are designed for separating substances for various industrial processes and applications.

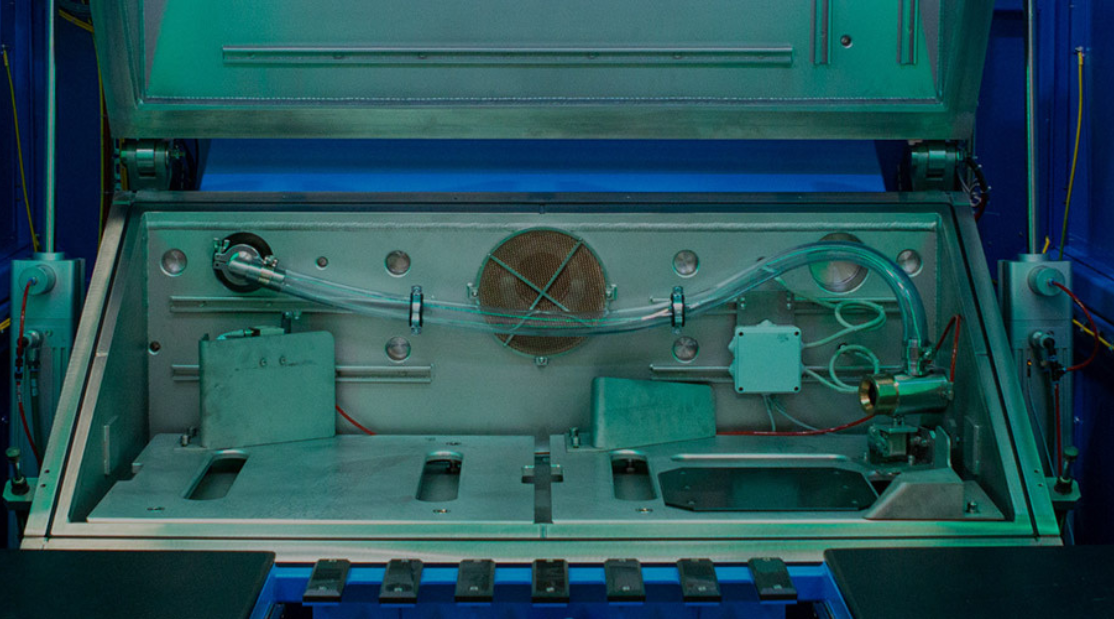

When the leak test system is operational, each membrane separator will arrive manually at the infeed trolley, then the handling robot will pick up and scan the component. The membrane separator is then placed into the helium leak test chamber, connected automatically, vacuum chamber door closes and the leak test begins.

If the membrane separator passes its leak test a robot will place it in the drying station. However, if the membrane separator fails its vacuum chamber leak test it with be removed and re-located by robot to the reject sniffing station for detailed leak location work using a helium sniffer probe.

Once the membrane is dried, a handling robot will transfer the membrane separator to the end of line area for final functionality testing.

The fully automated leak test system will provide comprehensive data collection, visualisation and traceability, along with recovering and reusing the helium trace gas.

For assistance with our single sourced, fully automated end-of-line leak detection solutions designed to reduce production timescales and operating costs – please contact our sales engineers by email at sales@vac-eng.com