Throwback Thursday!

Back in 2010, our engineers designed, manufactured and commissioned a series of leak detection systems for a renowned manufacturer of fire safety products.

The leak test systems were designed to accommodate testing a range of small 1 to 15 litre powder fire extinguishers using a 5% helium in nitrogen gas mixture.

The smaller fire extinguishers were leak tested in ergonomic angular vacuum chambers and the heavier large extinguishers slid onto the chamber base plate of vertical vacuum chambers.

Employing a ‘suck it and see’ philosophy, the pre-charged fire extinguishers underwent evacuation within the vacuum chamber until the measured leak rate fell below the acceptable pass/fail threshold.

To safeguard the leak test systems from potential contamination, time-out intervals were implemented at various stages of the test process. Notably, the system could test one part every 16 seconds, with the potential for increased throughput when multiple parts were loaded simultaneously.

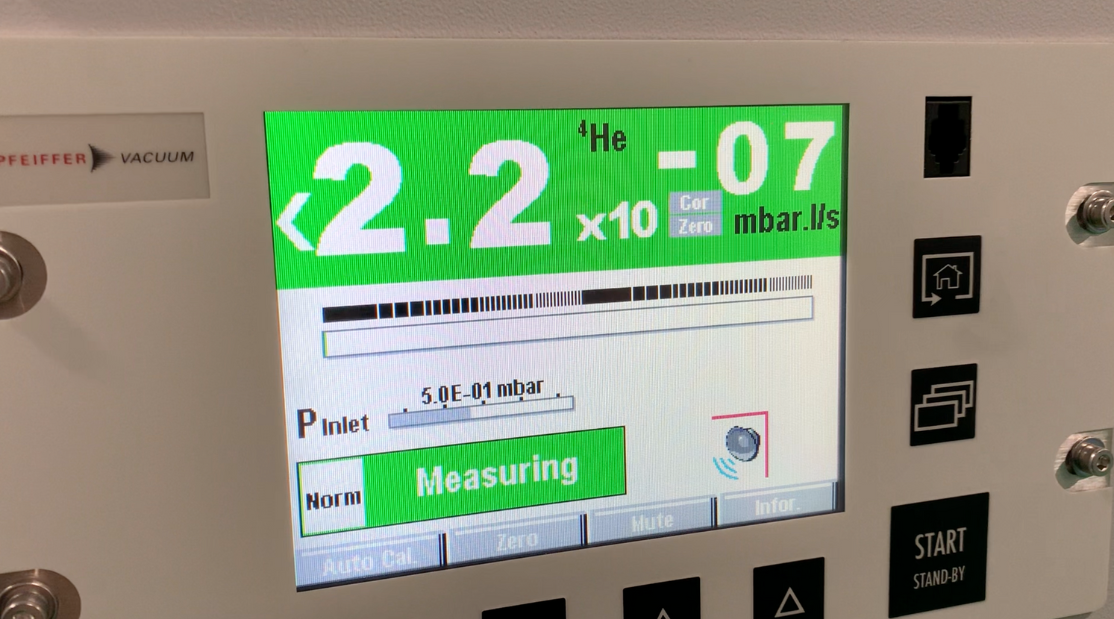

The systems could detect remarkably low leak rates, down to 7.0 × 10−7 mbar.l/s (approximately 7.0 × 10−7 cc/sec).

We’re still providing leading manufacturers of fire safety products with our customised leak detection solutions designed to reduce production timescales and operating costs – please contact our sales engineers by email at sales@vac-eng.com