What if you could detect even the tiniest leaks in your components without the complexity and cost of a vacuum chamber? For many manufacturers, accumulation testing provides that sweet spot, balancing sensitivity, repeatability, and operational simplicity. But like any testing method, it’s only as good as its implementation. Maximising the performance of your accumulation testing system means going beyond installation and diving into the finer details of process optimisation.

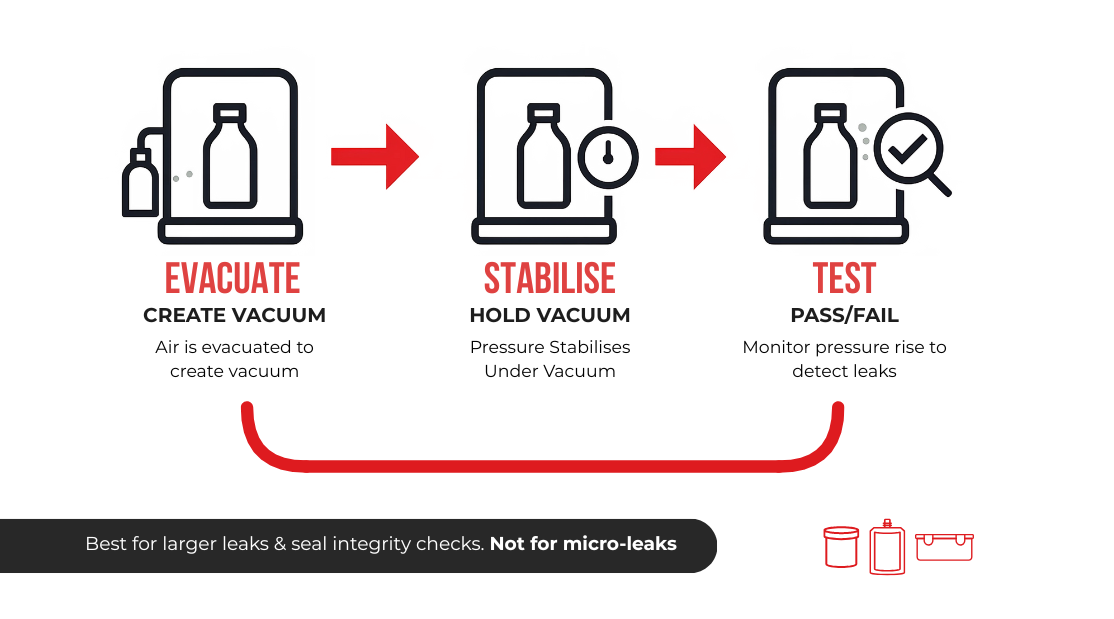

Understanding the Fundamentals

Accumulation testing is particularly effective for components that are awkwardly shaped, too large for vacuum chambers, or need to be tested at atmospheric pressure. It works by enclosing the part in a sealed environment and injecting helium; any leak allows helium to accumulate in the chamber, where it is measured over time. This technique avoids the need for deep vacuums and high-complexity setups, while still detecting leaks as small as 1.00E-3 mbar l/s. The result is a testing solution that’s more flexible and often more economical than hard vacuum methods, especially when designed and run with precision.

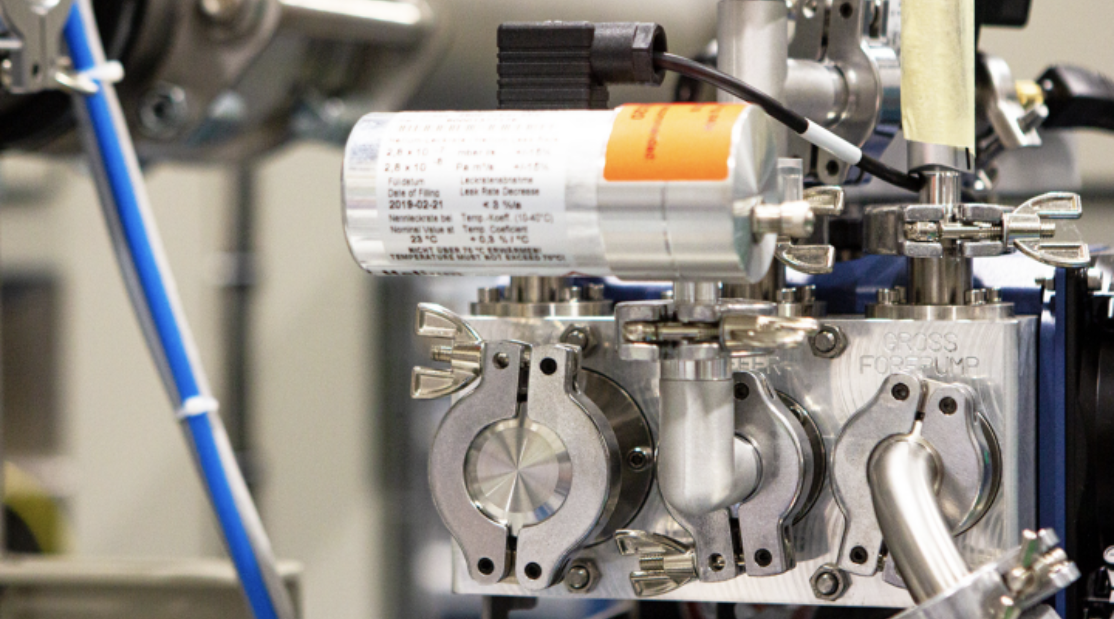

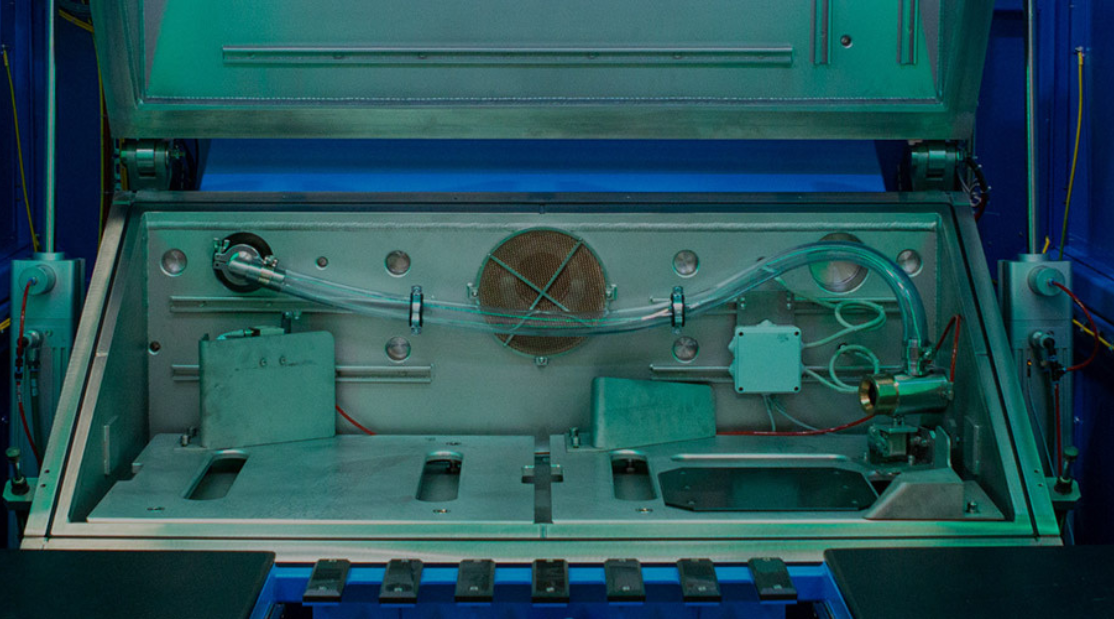

The Importance of Enclosure Design

The quality of your enclosure is central to your results. The goal is to detect how much helium is entering the environment, so minimising the enclosure volume boosts concentration and shortens test times. It is best to keep the enclosure as compact as possible, close-fitting to the part being tested without compromising seal integrity. Material choice also matters. Non-permeable materials like treated aluminium or stainless steel reduce helium absorption and prevent gas memory effects that can skew readings. Make sure your seals are robust and well-maintained. Leaks in the enclosure itself can result in false readings, increased background helium, and reduced confidence in test results.

Managing Background Helium

Ambient helium is the hidden saboteur in many test environments. If helium isn’t properly managed, it can linger in the air and enter the enclosure even when no leak is present. This distorts baseline readings and reduces test accuracy. To mitigate this, isolate your accumulation testing station from helium venting areas. Use extraction fans or dedicated exhaust systems to quickly remove helium after a test cycle. Routine background checks with no helium introduced are an excellent practice to ensure your sensors are working correctly and to establish a reliable zero baseline.

Using Helium More Efficiently

As helium costs continue to rise, smarter gas usage isn’t just good practice, it’s essential. Accumulation testers can be optimised to use helium blends, such as 5 percent helium mixed with nitrogen. While this lowers the helium concentration, it can still provide effective leak detection when used with sensitive sensors and well-calibrated systems. Helium recovery systems can take efficiency even further. By capturing and re-concentrating helium after a test, it is possible to dramatically reduce consumption and waste. Over time, this approach leads to substantial cost savings and helps reduce the environmental footprint of testing operations.

Staying Calibrated and Consistent

Consistency is everything in leak detection. Regular calibration using certified traceable leaks ensures your equipment is performing to specification. Depending on your production volume and risk profile, daily or weekly calibration cycles may be necessary. Sensors drift. Seals wear. Systems change. Staying on top of preventive maintenance and scheduled recalibrations protects your production from quality escapes and unexpected downtime.

Integrating with Your Production Flow

To truly get the most out of accumulation testing, it needs to be treated as an integral part of your production line, not just an extra step tacked on at the end. That means thinking carefully about how parts are handled before and after testing, how results are captured and used, and whether the test cycle fits smoothly into your existing workflow. Automation can make a big difference here. Whether it’s robotic part handling, barcode scanning for traceability, or smart data systems that feed directly into your quality control software, these tools all help improve reliability and speed. Even small upgrades like automated sorting based on test results can have a big impact when you’re working at scale.

Bringing It All Together

Accumulation testing offers a great combination of sensitivity, flexibility, and cost-effectiveness. When configured thoughtfully and maintained with care, the system is extremely reliable in any quality assurance process. We work with manufacturers around the world to design, refine, and support accumulation systems that meet demanding leak detection standards while keeping operational costs in check. If you’re looking to push your leak testing performance further, our team is here to guide you every step of the way.