Hydrogen is popping up everywhere right now. Cars, buses, trains, even planes are starting to run on it. But here’s the thing: hydrogen is not the easiest fuel to deal with. It is tiny, it is slippery, and it really does not like being contained. That is why hydrogen high pressure testing is so important. If you are putting hydrogen into a storage tank at 700 or even 900 bar, you need to be completely sure that tank will hold.

Why It Matters

Hydrogen is the smallest molecule in the universe, which means it can sneak through microscopic gaps in materials. Left unchecked, even the tiniest leak can cause big problems. At best, you are wasting fuel. At worst, you have a flammable gas leak in an enclosed space. Nobody wants that. So testing is not just a formality. It is the foundation of making hydrogen a safe and reliable fuel.

The Challenges

Testing hydrogen is not simple. Traditional methods bring a few headaches:

- Helium has been the go-to tracer gas for years, but it is getting expensive and harder to source.

- Helium-based systems need bulky storage, compressors, and recycling equipment.

- Composite materials used in hydrogen tanks sometimes give off gases during testing, which can confuse results.

- Even small temperature or pressure changes in the environment can throw off accuracy.

These challenges mean the industry has had to rethink how it approaches leak detection.

What Good Testing Looks Like

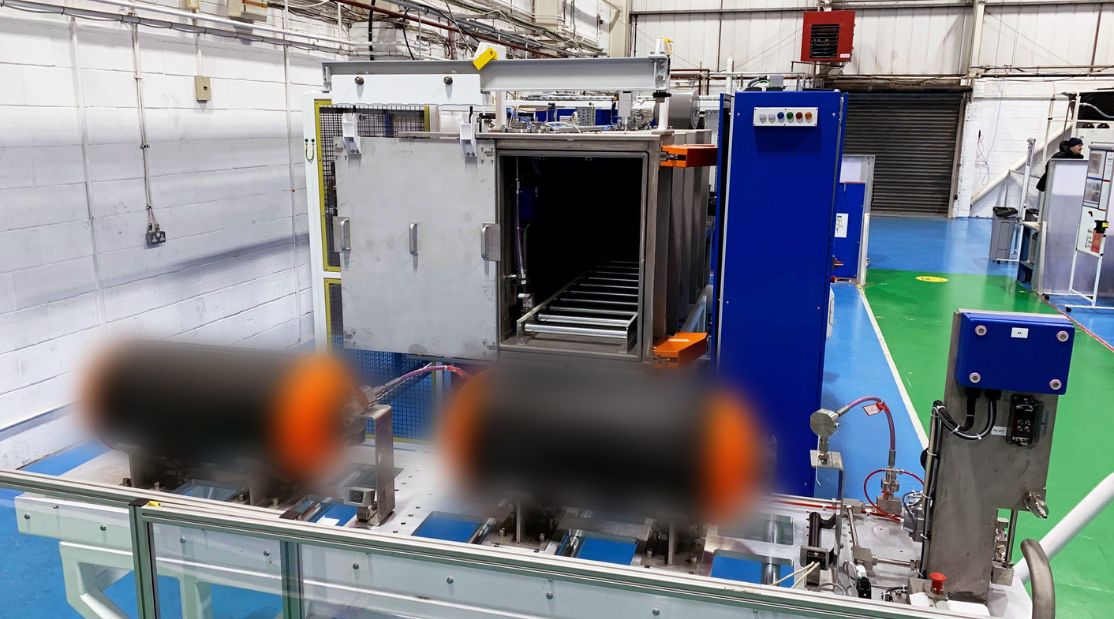

A proper hydrogen high pressure testing setup pushes parts to 350, 700, or even 875 bar. The goal is to stress tanks, valves, and fittings until you are confident they can handle real-world conditions. A strong system usually includes:

- A reliable high-pressure gas supply and control system

- Test chambers that can handle serious pressure

- Sensors sensitive enough to spot even the smallest leaks

- Safety systems to control venting and recovery

- Data logging tools that prove compliance and track performance

This is not just about catching faults. It is about building confidence that these parts are safe to put into vehicles and equipment.

The Rules Everyone Has to Play By

If you are building hydrogen storage systems, you have to meet tough international standards. Europe has R134, the US uses ASME, Japan has KHK, China requires SELO, and there are more. Each comes with slightly different requirements, but the idea is the same: prove your tanks are safe before they go into service.

Smarter Ways to Test

Technology is moving quickly, and testing methods are changing with it. Manufacturers now use a mix of approaches depending on what they are testing:

- Helium leak detection for ultra-precise results

- Hydrogen sniffing for real-time monitoring

- Pressure and vacuum decay tests for reliable integrity checks

- Forming gas (hydrogen and nitrogen blends) as a safer, cheaper tracer

- Nitrogen testing as a greener, cost-effective option

- Smart monitoring systems that pick up abnormal temperature changes which can indicate a leak

The aim is to keep accuracy high while keeping costs and complexity under control.

Scaling Up

Hydrogen demand is growing fast, so testing systems need to be quick, scalable, and reliable. Automation already helps by removing human error and making results more consistent. Gas recovery systems bring costs down by recycling expensive tracer gases. Modular setups make it easier to expand capacity without rebuilding entire facilities.

Why Testing Is the Key to a Safe Hydrogen Future

At the end of the day, hydrogen high pressure testing is about more than ticking a box. It is about building trust. If people are going to embrace hydrogen as part of the green energy future, they need to know it is safe. By investing in advanced testing methods and smarter setups, manufacturers are making that future possible.