Ensuring safety in hydrogen storage vessels is of paramount importance, especially as hydrogen emerges as a leading clean energy source. The TCATSI 02 007-2020 standard outlines critical safety features, including Temperature-Activated Pressure Relief Devices (TPRDs) and seals, which are essential for safeguarding the integrity and longevity of hydrogen storage systems. This article will delve into these advanced safety features, detailing their specifications and the critical role they play in maintaining the highest levels of safety and reliability in hydrogen storage vessels.

Temperature-Activated Pressure Relief Devices (TPRDs)

Role and Importance: TPRDs are designed to release pressure from hydrogen storage vessels in a controlled manner during high-temperature events, such as fires. This prevents the pressure within the vessel from reaching dangerous levels, thus averting potential explosions.

Specifications:

- Material: TPRDs must be made from materials that can withstand high temperatures. They typically use fusible alloy plugs or glass balls.

- Operating Temperature: The operating temperature for TPRDs should be (110±5)°C. This precise temperature range ensures that the TPRDs activate at the right moment to release pressure safely.

- Design: The relief port of the TPRD must not face the cylinder body to avoid direct exposure to the hydrogen vessel’s contents.

Testing and Qualification:

- Type Test Methods: The type test methods and qualification indicators for TPRDs are specified in Appendix B of GB/T 35544. These tests ensure that the TPRDs function correctly under specified conditions.

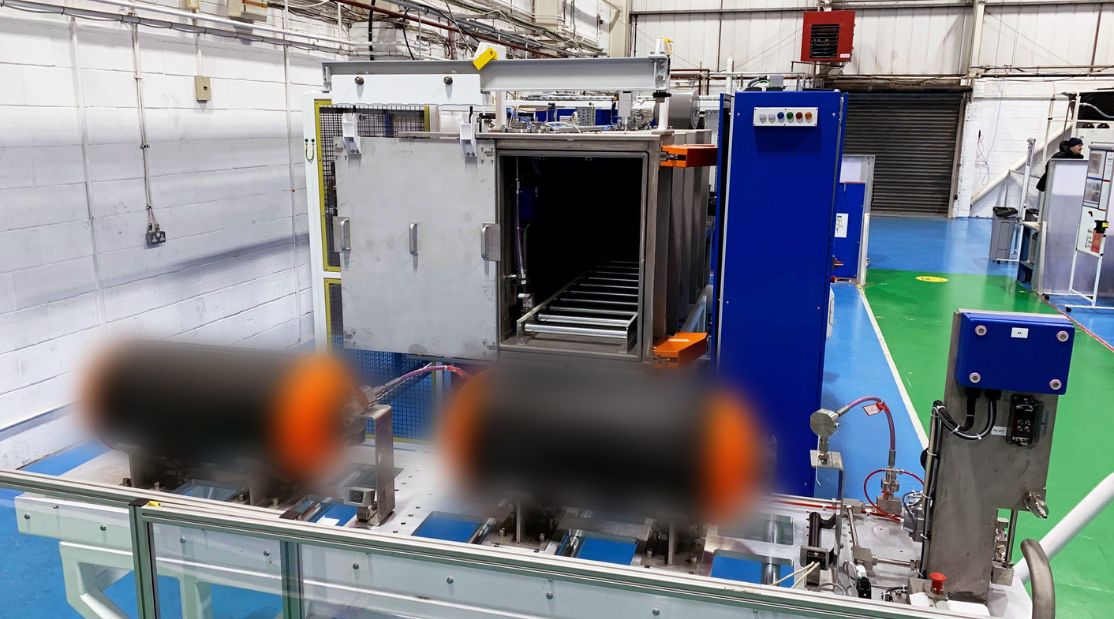

- Fire Test: The TCATSI 02 007-2020, gas cylinders equipped with TPRDs are subjected to fire tests. During the test, the cylinder is pressurised with hydrogen to its nominal working pressure and exposed to fire. The TPRD must activate within the specified temperature range, allowing the hydrogen to escape safely and continuously without causing an explosion.

Seals

Role and Importance: Seals are essential for maintaining the integrity of hydrogen storage vessels by preventing hydrogen leaks. High-quality seals ensure that the storage system remains airtight under varying pressures and temperatures.

Specifications:

- Material: Seals must be made from polymers compatible with high-pressure hydrogen, such as silicone rubber, fluororubber, fluorosilicone rubber, fluorocarbon rubber, EPDM rubber, or hydrogenated nitrile rubber.

- Operating Temperature Range: The seal material must operate effectively within a temperature range of -40℃ to 85℃. This ensures the seals perform reliably under the conditions specified for hydrogen storage vessels.

- Performance: The performance of the seal materials is evaluated based on criteria such as compression set, hardness change, hydrogen damage, and temperature shrinkage tests.

Testing and Qualification:

- Hydrogen Leak Test: After the water pressure test, an air tightness test is conducted at (15±5)°C to ensure the hydrogen leakage rate does not exceed 6 NmL/(h·L).

- Compression Set Test: This test evaluates the deformation of the seals under pressure, ensuring they maintain their sealing capability.

- Hardness Change Test: This test measures any changes in the hardness of the seal material after exposure to hydrogen and varying temperatures.

- Temperature Shrinkage Test: This test assesses the shrinkage of the seal material at different temperatures, ensuring it remains effective in sealing the vessel.

Implementation and Maintenance

Design and Installation:

- Proper Installation: Ensuring the correct installation of TPRDs and seals is crucial. The design of the hydrogen storage vessel should accommodate these components, providing adequate protection and accessibility.

- Regular Inspections: Periodic inspections are necessary to maintain the functionality of TPRDs and seals. The TCATSI 02 007-2020 standard mandates regular checks and maintenance to identify and address any wear or damage.

Conformity to Standards:

- Compliance with TCATSI 02 007-2020: Adhering to the specifications and testing protocols outlined in the standard ensures that hydrogen storage vessels are safe and reliable.

- Batch Testing: Consistent batch testing of TPRDs and seals is essential to verify that each production lot meets the required safety standards.

Ensuring Hydrogen Storage Safety with Advanced TPRDs and Seals

Implementing advanced safety features such as Temperature-Activated Pressure Relief Devices (TPRDs) and high-quality seals is vital for the integrity and safety of hydrogen storage vessels. At VES, we are committed to providing innovative and reliable testing solutions that help manufacturers comply with TCATSI 02 007-2020 standards. By adhering to these stringent requirements and maintaining rigorous testing protocols, we contribute to the safe and sustainable use of hydrogen as a clean energy source.