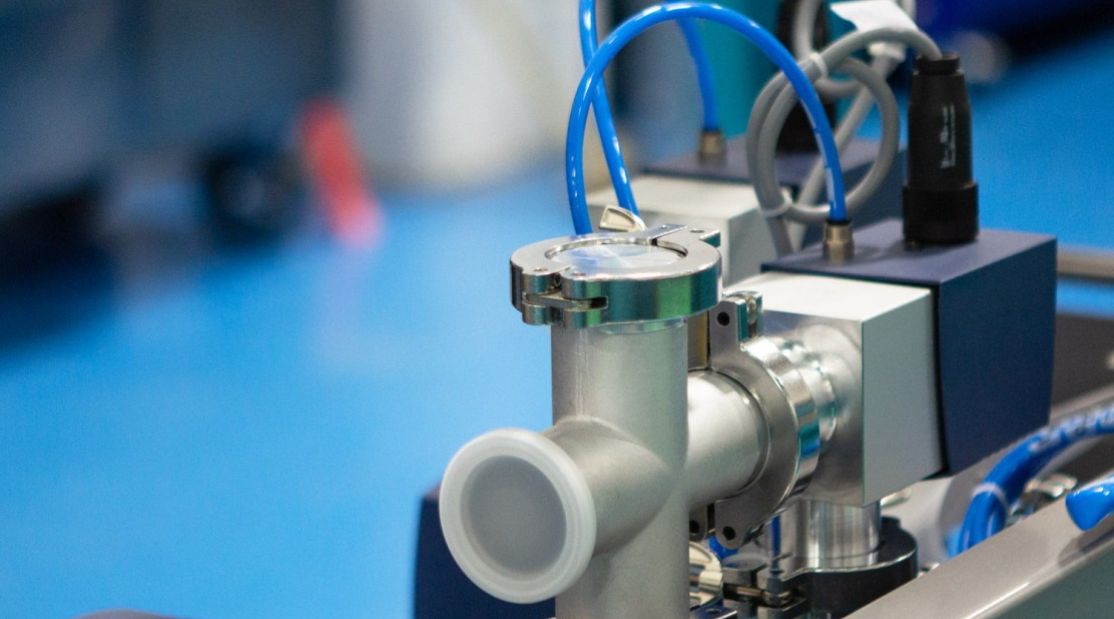

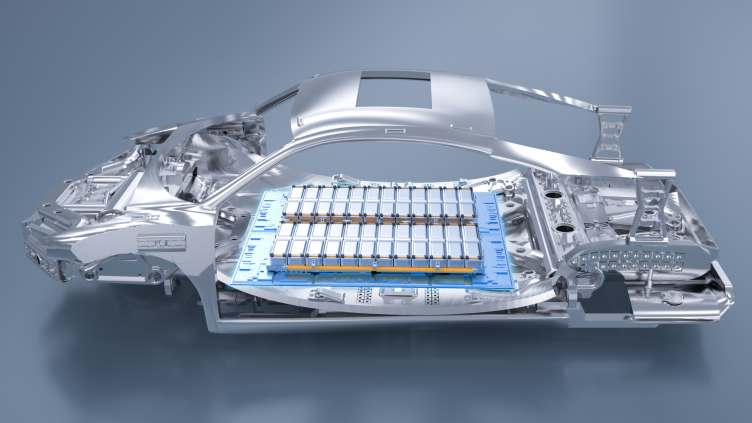

Leak testing is an essential part of the manufacturing process for many industries, including automotive, aerospace, and medical device production. It ensures that products are safe, reliable, and meet quality standards. However, leak testing is not without its challenges, and manufacturers often face issues that can impact the efficiency and accuracy of the process.

In this article, we will explore some of the common challenges in leak testing and provide tips on how to overcome them.

Testing Different Products with Different Requirements

Manufacturers often produce multiple products with different requirements for leak testing. This means that they need to change the testing parameters, such as the pressure and test time, for each product. This can be time-consuming and can lead to errors if the parameters are not set correctly.

To overcome this challenge, manufacturers can use automated leak testing systems that allow them to program and save different testing parameters for each product. This reduces the risk of errors and ensures that the testing process is efficient.

Testing Large or Complex Components

Testing large or complex components can be challenging as it is difficult to identify the exact location of a leak. This can lead to false positives or negatives and can impact the accuracy of the testing process.

To overcome this challenge, manufacturers can use tracer gas leak testing, which uses a gas, such as helium, to detect leaks. The gas is introduced into the component, and a mass spectrometer is used to detect any leaks. This method is highly accurate and can detect leaks in even the most complex components.

Maintaining Consistency in Testing Results

Manufacturers need to ensure that the testing results are consistent and reliable. However, changes in temperature, pressure, or other environmental factors can impact the accuracy of the testing process in methods such as pressure decay and lead to inconsistent results.

To overcome this challenge, manufacturers can use testing systems that are designed to compensate for environmental changes. For example, VES’ OptVol Technology uses a patented system that ensures that the testing results are accurate and consistent, even in changing environmental conditions.

Avoiding False Positives or Negatives

False positives or negatives can be a significant challenge in leak testing, as they can impact the quality of the product and lead to unnecessary repairs or recalls.

To avoid false positives or negatives, manufacturers can use testing systems that are highly accurate and reliable. For example, VES’ helium leak testing systems use highly sensitive mass spectrometers that can detect even the smallest leaks. This reduces the risk of false positives or negatives and ensures that the testing results are reliable.

Balancing Cost and Quality

Manufacturers need to balance the cost of leak testing with the quality of the product. While highly accurate testing systems can be expensive, using cheaper systems can lead to lower quality products and an increased risk of recalls.

To overcome this challenge, manufacturers can use testing systems that are designed to be cost-effective without compromising on quality. For example, VES’ OptVol Technology is highly efficient and cost-effective, with a 92% reduction in power consumption and a 44% reduction in helium consumption. This ensures that manufacturers can achieve high-quality testing results without incurring significant costs.

Leak testing is an essential part of the manufacturing process, but it comes with its challenges. By using automated testing systems, tracer gas leak testing, compensation systems, highly accurate testing systems, and cost-effective testing systems, manufacturers can overcome these challenges and achieve high-quality testing results. As experts in helium leak detection, VES can provide manufacturers with the solutions they need to ensure that their products are safe, reliable, and meet quality standards.