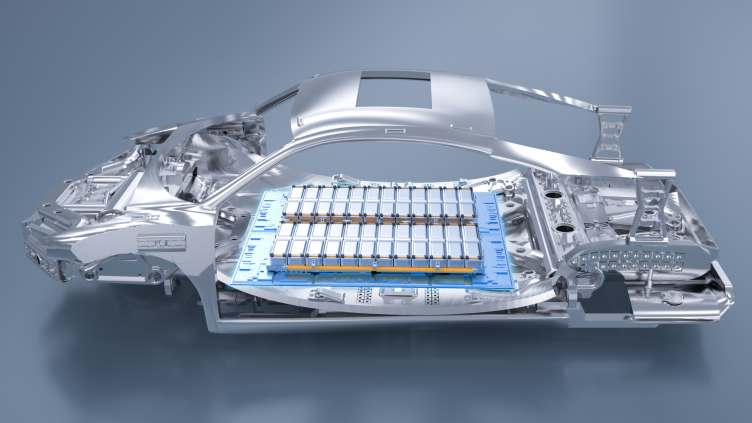

The automotive industry has been undergoing a significant shift in recent years, with the rise of electric vehicles and the increasing use of lithium-ion batteries. While these batteries offer many advantages over traditional combustion engines, they also pose unique challenges, including the risk of battery cell leaks.

Battery cell leaks can have a significant impact on the automotive industry, affecting both the safety and reliability of electric vehicles. In this article, we will explore the impact of battery cell leaks on the automotive industry and the measures that manufacturers can take to prevent these leaks from occurring.

The Dangers of Battery Cell Leaks in Electric Vehicles

One of the most significant dangers of battery cell leaks in electric vehicles is the risk of fire. When the electrolyte in a lithium-ion battery comes into contact with air or water, it can produce flammable gases that can ignite under certain conditions, such as high temperatures or an electrical short circuit. This can cause the battery to catch fire or even explode, posing a significant risk to both the vehicle and its occupants.

Battery cell leaks can also have an impact on the overall efficiency and performance of electric vehicles.

When a battery cell leaks, it can reduce the overall capacity of the battery pack, leading to reduced range and performance. Additionally, if the leak is not detected and repaired, it can cause other cells in the battery pack to fail, leading to a domino effect of reduced performance and potential safety hazards.

Preventing Battery Cell Leaks in Electric Vehicles

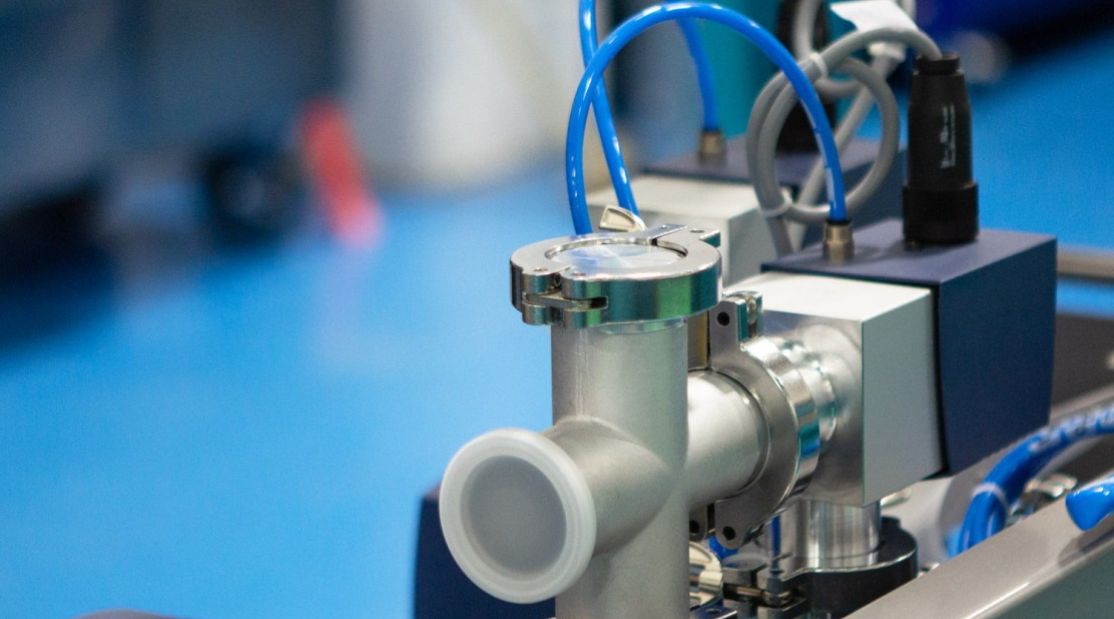

The best way to prevent battery cell leaks in electric vehicles is to implement rigorous quality assurance measures throughout the battery manufacturing process. This includes leak testing each cell and module, as well as conducting comprehensive performance and safety testing before the batteries are installed in vehicles.

In addition to leak testing, there are other measures that manufacturers can take to prevent battery cell leaks in electric vehicles. These include implementing strict manufacturing standards, using high-quality materials, and ensuring that all employees are properly trained in battery cell manufacturing and safety protocols.

However, even with these measures in place, it is vital to have a rigorous quality assurance program in place to ensure that any faults are identified before battery cells reach consumers.