You’ve probably noticed fuel cells are popping up everywhere. Clean transport, backup power, industrial energy systems… things are picking up fast. And while the tech is impressive, there’s one part that’s always essential to get right: leak detection.

It’s not the flashiest part of production, but fuel cells leak detection is one of the most important. Done right, it keeps systems safe, efficient, and performing at their best. Skip it or get it wrong, and you’re dealing with costly reworks, compliance headaches, or worse, a product that fails in the field.

Let’s break down why it matters, what makes it challenging, and how to get it working seamlessly in your process.

Why Fuel Cells Leak Detection Is So Important

Fuel cells convert hydrogen into electricity through a carefully controlled electrochemical reaction. It’s smart, clean tech, but it’s also delicate. These systems are built with layers of components like anodes, cathodes, and membranes that all need to be perfectly sealed.

Even a tiny breach can throw everything off. It might let gas escape, introduce contaminants, or just push the whole unit out of spec. That can lead to performance issues, missed certifications, or total failure in the field.

That’s why fuel cells leak detection is a must-have, not a nice-to-have. Whether you’re building single cells, full modules, or complete stacks, you need to be sure every part is sealed tight and ready to perform.

The Challenges That Come With It

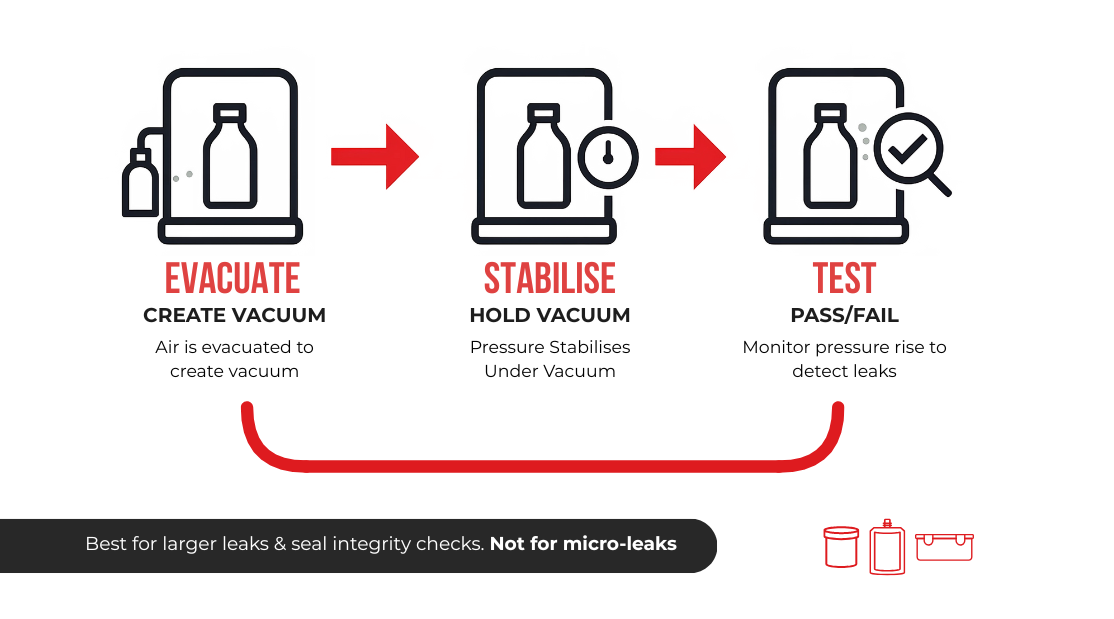

Here’s where it gets tricky. Fuel cells often have complex shapes, thin walls, and materials that don’t always play nicely with traditional testing methods like pressure decay. On top of that, you’re usually working with very small, sensitive parts and leak rates that are incredibly low.

We’re talking about leak rates down to 2 x 10⁻⁵ mbar litres per second. Hitting that target consistently means using a system built specifically for the job, one that’s accurate, fast, and repeatable under real production conditions.

You’ve also got to avoid false positives, which can slow down production or cause you to scrap perfectly good parts. It’s a balancing act between speed and sensitivity, and not every method can handle it.

Tracer Gas Testing That Works

One of the most effective solutions? Tracer gas testing. Helium or hydrogen are the go-to choices here. These gases make it possible to spot even the tiniest leaks without damaging parts or interfering with your environment.

Depending on your setup, either vacuum-based or accumulation-based testing can work best. Vacuum systems are ideal when you need absolute precision in a controlled space. Accumulation methods are better for high-throughput lines where speed still matters.

Both approaches give you consistent, traceable results and that’s a big deal when you’re aiming for compliance or certification. It also means you can prove your process works, which makes life a lot easier when you’re dealing with partners or regulators.

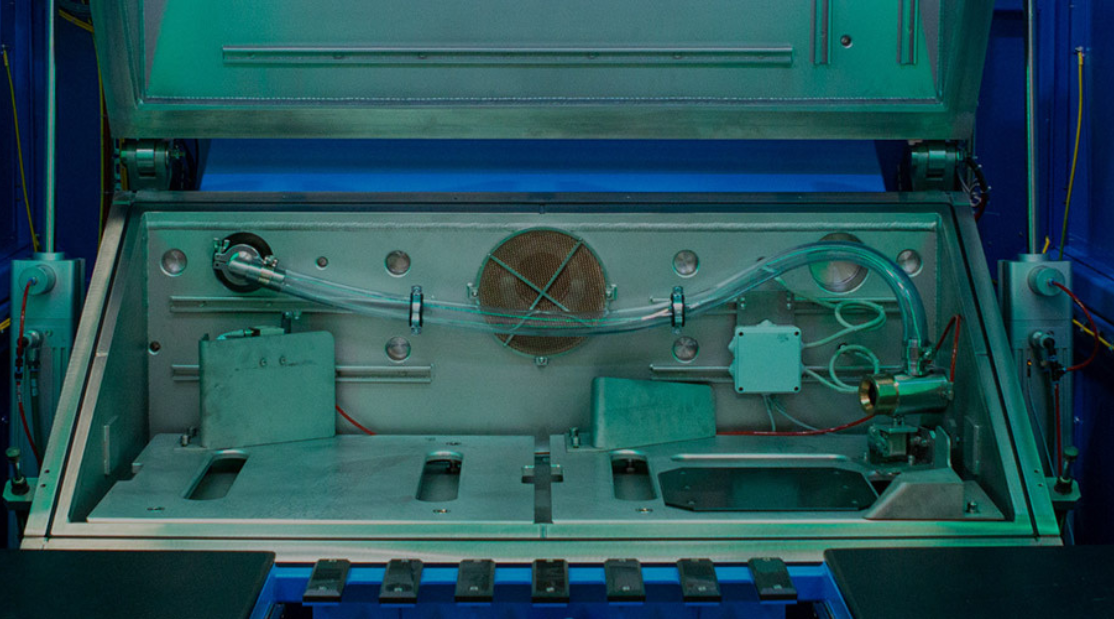

Seamless Integration into Your Line

Modern leak detection doesn’t have to be a bottleneck. Today’s systems are compact, modular, and designed to plug straight into your production line. You can switch between product variants quickly, scale up as needed, and keep everything running smoothly without adding delays.

And if you’re working with helium, recovery systems are available that let you reuse the gas across multiple cycles. That’s a huge cost-save, especially with helium prices rising and a win for sustainability too.

Real-Time Data That Drives Decisions

Leak detection isn’t just about pass or fail anymore. It’s a source of valuable data that can help improve quality, traceability, and process control across your line.

The best systems feed results straight into your manufacturing software, so engineers can track trends, catch issues early, and make confident decisions based on solid data. That level of visibility gives you more control and helps you move faster without cutting corners.

Get It Right from Day One

Choosing a leak detection system isn’t just about ticking a box. It needs to work with your specific process, your components, and your team. That means proper setup, calibration, and support to make sure it delivers.

The good news? With the right tools and approach, you can build a leak detection process that’s fast, accurate, and ready for the demands of fuel cell production.

And once you’ve got it dialled in, everything else from compliance to quality to customer trust gets that much easier.