As industries move toward hydrogen and other clean energy sources, the focus is on creating systems that are safe, reliable, and efficient. Leak testing, though often behind the scenes, is proving to be one of the most essential processes in this transition. At VES, we’re proud to play a role in this change by providing solutions that meet the demands of a sustainable future.

Why Leak Testing Matters

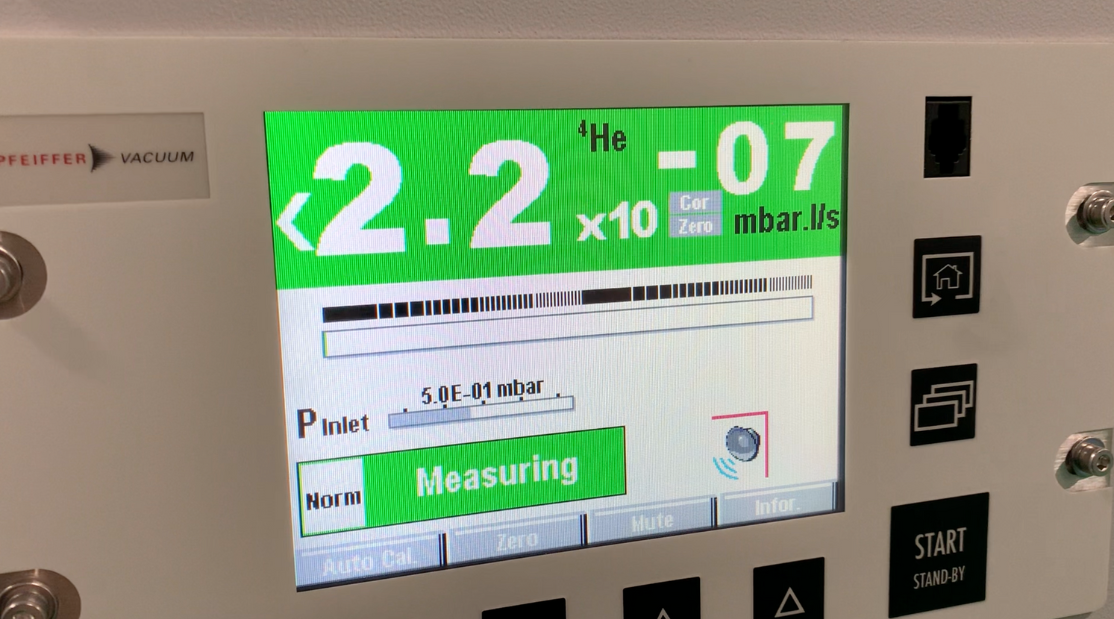

In traditional energy systems, leaks might mean minor inefficiencies or localised hazards. However, in green energy applications, particularly hydrogen storage, leaks can have far-reaching consequences. Hydrogen is stored and transported under extremely high pressure—up to 700 bar in some cases. Even a tiny leak can lead to major safety risks, loss of valuable gas, and, in worst cases, an environmental or economic setback.

Hydrogen’s unique properties make it especially challenging. As the smallest and lightest molecule, it’s difficult to contain. Add its highly flammable nature, and the stakes become even higher. This is why rigorous, precise leak testing isn’t just a technical step—it’s the foundation for making hydrogen a safe and viable energy option.

Supporting a Sustainable Future

Beyond safety, leak testing is a vital part of making green energy systems more efficient and sustainable. One of the key advancements has been the use of nitrogen as an alternative tracer gas to helium. Helium, while effective, is in short supply and expensive. Transitioning to nitrogen not only reduces costs but also addresses global supply concerns.

Leak testing also supports sustainability through the recovery and reuse of testing gases. Manufacturers are increasingly adopting systems that allow the collection and recycling of gases, minimising waste. These innovations contribute to the larger goal of reducing the environmental footprint of green energy technologies.

Scaling for Tomorrow

One of the biggest challenges in the green energy transition is scaling production to meet growing global demand. Whether it’s hydrogen-powered vehicles or large-scale energy storage systems, the ability to produce components efficiently and at scale is essential.

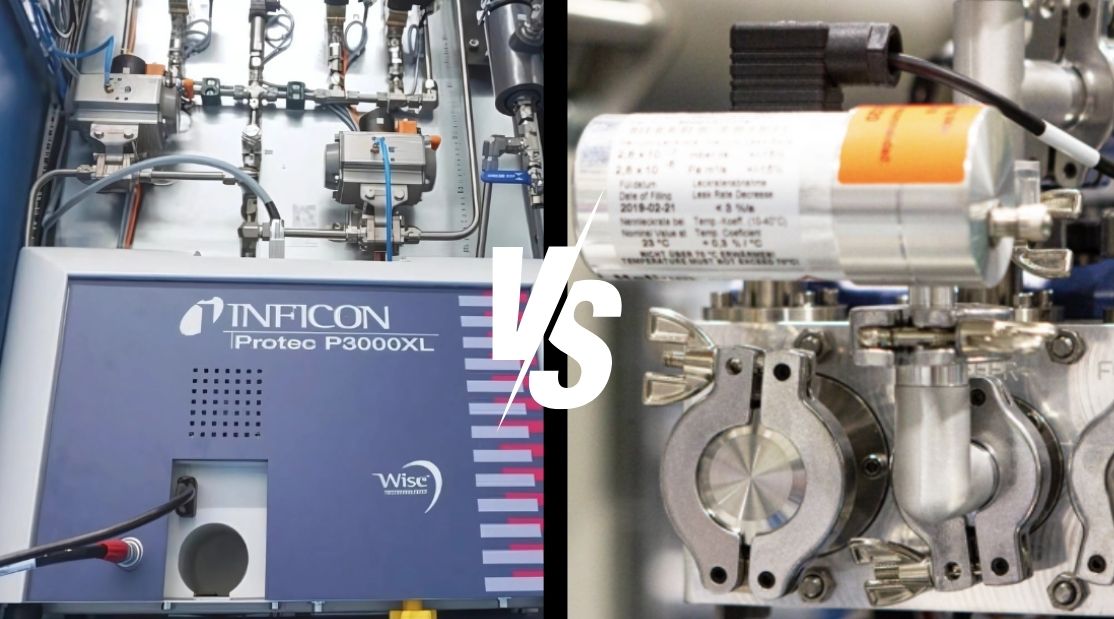

Traditional leak testing methods, designed for small-scale production, struggle to keep up with high-volume manufacturing. Modern systems have stepped in to fill this gap, offering flexible, modular designs that can expand as production ramps up. These systems save time, reduce costs, and make it easier for manufacturers to meet market demands without compromising on quality.

This scalability is particularly important for industries like hydrogen storage, where regulations are becoming stricter and demand is rising. Leak testing is no longer just a quality check—it’s a vital part of the production process.

Building Trust in Green Energy

Leak testing plays a significant role in building trust—both for consumers and industry players. By ensuring that hydrogen systems are leak-free and safe to use, manufacturers can foster confidence in these new technologies. Confidence is what drives adoption, whether it’s a consumer buying a hydrogen-powered car or a government investing in large-scale green energy projects.

As regulatory bodies introduce stricter standards for hydrogen systems, precise leak testing becomes even more necessary. Manufacturers that can meet or exceed these standards will have a clear advantage in the marketplace.

The Path Forward

At VES, we’ve been working closely with manufacturers to develop leak testing solutions that meet the unique demands of green energy. From high-pressure hydrogen tanks to advanced fuel cell systems, our testing processes are designed to ensure safety, reliability, and efficiency.

The transition to green energy isn’t without its challenges, but the possibilities far outweigh the hurdles. Leak testing is an essential part of making this transition successful, ensuring that the systems we rely on are ready to meet the demands of a cleaner, more sustainable future.