Ensuring the safety and integrity of high-pressure hydrogen storage systems is paramount for manufacturers of composite hydrogen pressure vessels. VES specialises in providing innovative and compliant helium leak testing solutions designed to meet the rigorous requirements of standards like TCATSI 02 007-2020. This article will guide you through the application of Tightness, Containment, and Spill Prevention Testing (TCATSI) specifically for high-pressure hydrogen storage systems, detailing the procedures for tightness testing and containment verification, and demonstrating how our New Energies’ system meets global pressure regulations such as PEDG1, KGS, KHK, ASME, SELO, as well as TCATSI 02 007-2020.

Understanding TCATSI 02 007-2020

TCATSI 02 007-2020 is a comprehensive standard that specifies the requirements for fully-wrapped carbon fibre reinforced cylinders with plastic liners used for on-board storage of compressed hydrogen in land vehicles. This standard covers the design, manufacturing, testing, inspection, and installation protection of these cylinders, ensuring they meet the highest safety and performance criteria.

Key Procedures for Tightness Testing

1. Initial Preparation

Before beginning the tightness testing, it’s essential to ensure that all materials and equipment meet the specified standards. The plastic liners should be made of polyethylene or polyamide, with proven compatibility with hydrogen. The cylinders must withstand extreme conditions, including temperatures from -40°C to 85°C, and be resistant to chemical attacks, UV radiation, and mechanical impacts.

2. Hydrostatic Test

The first step in tightness testing is the hydrostatic test, which involves filling the cylinder with water and pressurising it to 1.5 times its nominal working pressure. This test checks for any structural weaknesses or leaks in the cylinder. The TCATSI 02 007-2020 standard specifies that the hydrostatic test pressure should be maintained within a tolerance of ±1 MPa when using gas, and (0~+2) MPa when using liquid.

3. Pressure Cycling Test

Following the hydrostatic test, the cylinder undergoes a pressure cycling test, where it is repeatedly pressurised and depressurised to simulate real-world conditions. This test ensures that the cylinder can withstand the cyclic stresses it will encounter during its service life. The standard requires the cylinders to endure a minimum of 11,000 pressure cycles, reflecting their designed service life of 15 years.

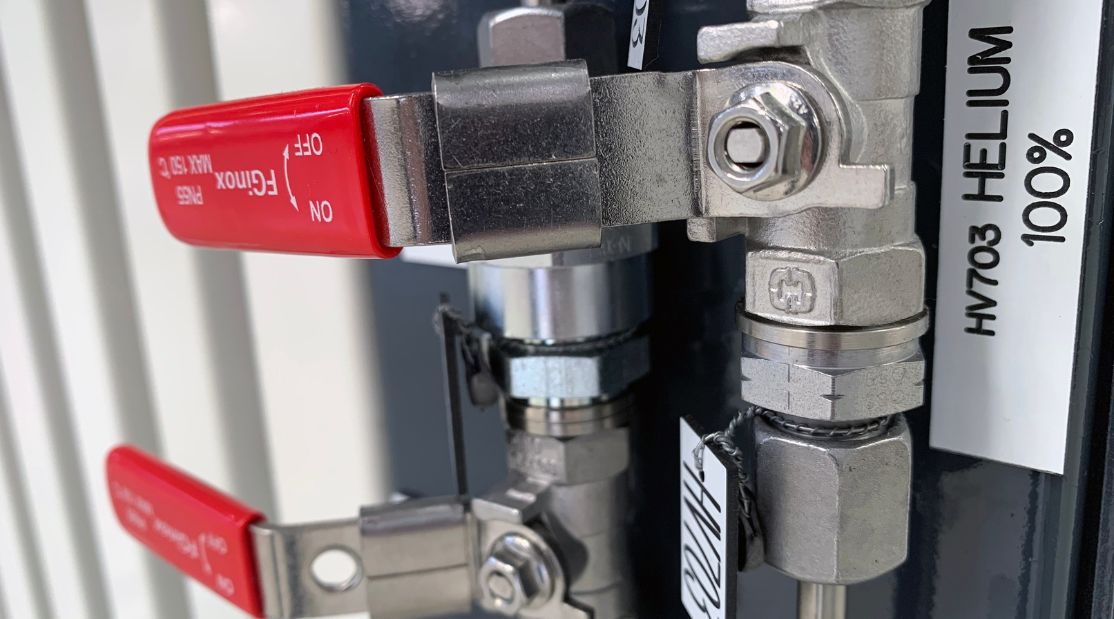

4. Helium Leak Detection

Next up is Helium leak detection. Our leak testing systems are designed to comply with a variety of international standards, including:

- PEDG1 (Pressure Equipment Directive): Ensures compliance with European pressure vessel safety requirements.

- KGS (Korean Gas Safety): Meets South Korean gas safety regulations.

- KHK (KHK Japan): Complies with Japanese pressure vessel standards.

- ASME (American Society of Mechanical Engineers): Adheres to the ASME Boiler and Pressure Vessel Code.

- SELO (Special Equipment Licensing Office): Conforms to Chinese pressure equipment regulations.

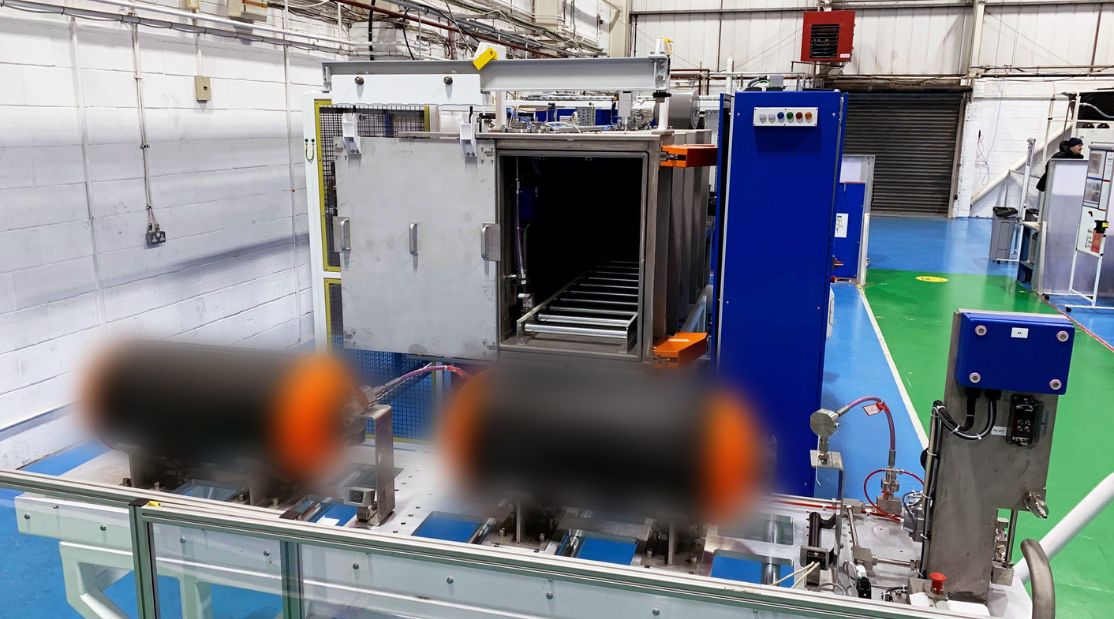

The VES New Energies system offers modular and flexible solutions that can be tailored to meet specific production demands, providing robust safety, ease of implementation, and comprehensive regulatory support. This ensures manufacturers can ship their hydrogen pressure vessels with confidence, knowing they meet all necessary safety and compliance standards.

Containment Verification

Containment verification ensures that the hydrogen remains securely stored within the vessel, preventing any accidental releases that could pose safety risks.

1. Permeation and Leakage Tests

The TCATSI standard outlines specific requirements for permeation and leakage. Permeation refers to the process of hydrogen molecules passing through the cylinder’s material, while leakage involves hydrogen escaping through defects or interfaces. The standard sets strict limits on both permeation and leakage rates to ensure safety and performance.

2. Burst Test

The burst test is conducted to verify the cylinder’s ability to withstand pressures significantly higher than its nominal working pressure. This test involves increasing the pressure inside the cylinder until it bursts, ensuring that it fails safely without posing any danger. According to TCATSI 02 007-2020, the minimum burst pressure should be at least 2.25 times the nominal working pressure.

3. Fire Test

To ensure the cylinders can withstand extreme conditions, a fire test is conducted. This involves exposing the cylinder to high temperatures to simulate a fire scenario and verifying that the safety release devices function correctly to prevent catastrophic failures. The plastic liner material must have a high melting point to ensure the safe release of hydrogen during a fire.

Implementing TCATSI 02 007-2020 for hydrogen storage vessels involves rigorous testing and verification procedures to ensure safety and compliance. We provide turnkey solutions that integrate seamlessly into production lines, delivering precise, reliable leak detection and containment verification.

By adhering to global pressure regulations, VES New Energies can work alongside manufacturers to enable them to confidently produce and distribute high-pressure hydrogen storage systems that meet the highest standards of safety and performance.