Helium has long been the gold standard for leak testing. It’s clean, non-reactive, and highly sensitive, which makes it ideal for detecting even the smallest leaks in pressure vessels, HVAC systems, battery components, and fuel cells. But lately, more and more manufacturers are asking the same question:

Why is helium suddenly such a problem for our budget?

At VES, we hear this concern regularly. Whether you’re running high-volume production or still ramping up, the rising cost of helium and the uncertainty around supply can create real challenges. But the good news is that there are practical steps you can take to bring those costs under control without compromising the quality of your leak testing.

Why Helium Costs Are Getting Out of Hand

It’s not just you. The cost of helium has climbed sharply in recent years. Global shortages, limited sources of extraction, and rising demand in sectors like medical imaging and semiconductors have all pushed prices up.

And if you’re using helium at scale in your production line, it’s easy to lose track of how much you’re consuming until the invoices arrive. Even small increases in price per litre can have a major impact on your bottom line, especially if you’re testing multiple components per minute or running multi-shift operations.

Worse still, helium is often treated as a consumable rather than an asset. Once it’s used, it’s vented, gone for good. But it doesn’t have to be.

Step One: Start Recovering Your Helium

One of the most effective ways to cut helium costs is to stop wasting it. With our recovery system, the helium you use for testing can be captured, purified, and reused, significantly reducing your operating costs over time.

Our units can recapture helium after each test, remove contaminants, and feed it back into your system with minimal loss. Over the course of a year, this can translate into substantial savings, especially in high-volume environments.

It’s not just about cost either. Recovery helps protect your operation from supply shortages and price spikes. If global helium availability tightens, you’ll already have a system in place to stay productive.

Step Two: Use Less Helium Per Test

Another way to reduce costs is to optimise how much helium you’re using in the first place. Many older systems rely on 100% helium for every test cycle, which is not only expensive but often unnecessary.

Our leak test systems can use helium blends, typically mixed with nitrogen or air, that still meet sensitivity requirements but use far less pure helium. These blends are more affordable and can still deliver the precision needed to detect critical leaks.

Step Three: Reassess Your Testing Method

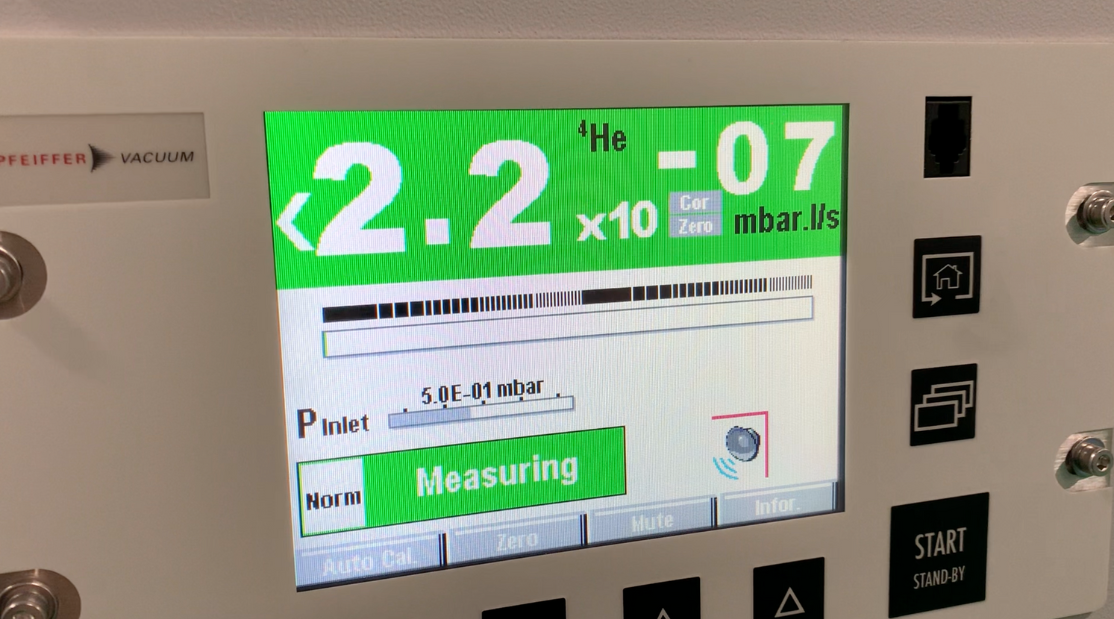

Not all leak test methods are created equal when it comes to helium consumption. If you’re using sniff testing or pressure decay, you might be using more helium than needed or getting less reliable results.

Consider switching to vacuum-based testing or accumulation methods where possible. These approaches are not only more accurate for many applications, but they also tend to be more efficient with gas usage.

The goal isn’t just to cut gas consumption but to create a test process that is stable, repeatable, and cost-effective over the long term.

Step Four: Monitor and Control Your Helium Usage

If you’re not already tracking your helium consumption closely, now is the time to start. Leak test systems with integrated helium flow monitoring or usage reports can help you understand exactly how much gas is being used, where it’s going, and where you can improve.

This kind of visibility makes it easier to justify investments in recovery, switching test methods, or upgrading your system. It also gives your procurement or finance teams the data they need to manage costs more effectively.

Small changes, like tweaking flow rates or adjusting fill times, can add up to real savings when you’re running thousands of tests a day.

Saving Money Doesn’t Mean Lowering Standards

This is the part many manufacturers worry about. If we use less helium or recover it, are we still getting reliable results?

The answer is yes, as long as the system is built to handle it. With the right machine, process, and support, you can maintain full sensitivity and test integrity while cutting your helium usage by more than half. Some of our customers have reduced helium-related costs by over 90% per test part simply by switching to recovery and optimised blends.

That means fewer compromises, more control, and lower operating costs across the board.

Making Helium Work for You

We design leak test systems that help you take back control of helium usage. From advanced gas recovery to low-consumption test cycles and smarter blends, everything we build is aimed at giving you reliable results without the hidden costs. If helium is draining your budget and you’re looking for a better way to test, we’re here to help.