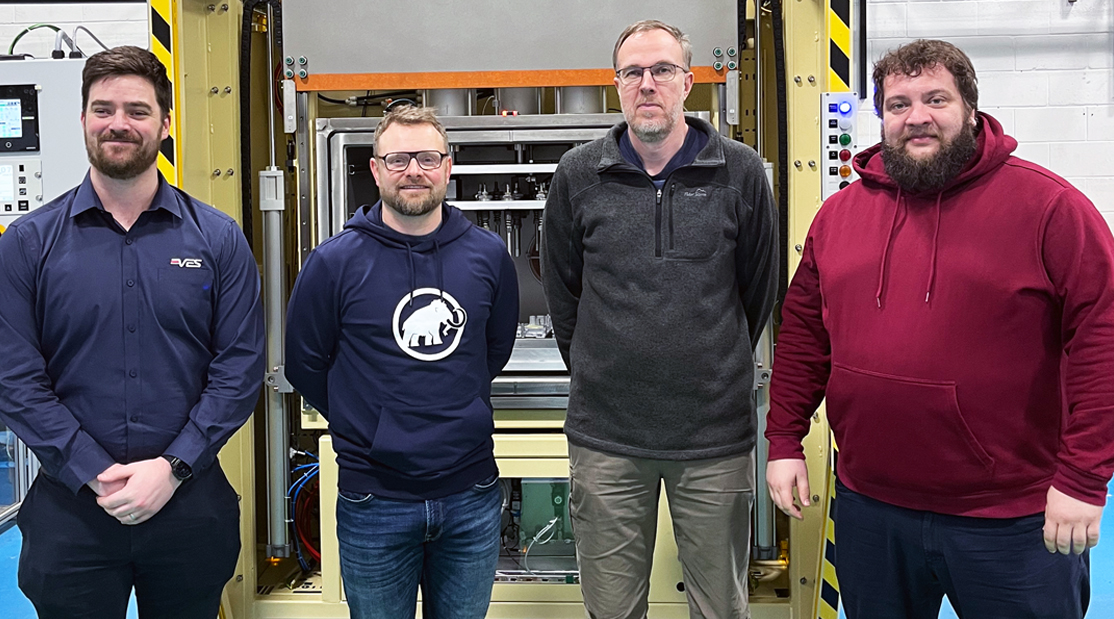

We’re engineering an automated end-of-line leak detection cell to ensure the integrity of hollow fibre membrane separators. These critical components enable precise substance separation for a wide range of industrial applications.

The automated system will optimise their leak testing process. Operators will manually load each membrane separator onto an infeed trolley, where a handling robot will then scan and precisely place it into the helium leak test chamber. Automated connections will establish a secure seal, the vacuum chamber door will close, and the leak test will initiate.

For assistance with our one-stop, single sourced, automated end-of-line leak detection solutions designed to reduce production timescales and operating costs – please contact our sales engineers by email at sales@vac-eng.com