When we talk about vehicle reliability, most people picture sleek designs or roaring engines. But behind all that is something less glamorous but equally vital, leak integrity. Whether it’s keeping hydrogen from escaping a high-pressure tank or making sure your EV battery doesn’t slowly degrade, automotive leak testing equipment is the quiet hero ensuring cars run safely, efficiently, and for the long haul.

As cars become cleaner and more high-tech, the pressure (pun intended) is on. These systems can’t afford leaks, not even the tiniest ones. Let’s dive into how modern manufacturers are tackling this invisible challenge.

Why Tiny Leaks Are a Big Deal

Some of the most damaging leaks are too small to see, yet they can still wreak havoc:

- Hydrogen Systems: Hydrogen is tricky. It’s the tiniest molecule and super flammable. So even the slightest leak can mean big safety risks and fuel loss. These systems operate under serious pressure (up to 900 bar!), so leak detection must be precise, like detecting-a-few-molecules precise.

- Battery Packs: If moisture sneaks into a battery, it can trigger a chain reaction of failures, not to mention fire risks.

- Airsprings: A leaky airspring means a wobbly ride. No one wants their EV sagging on one side.

Older methods like dunking parts in water or using basic air pressure just don’t cut it anymore. That’s why the industry is turning to smarter, more sensitive tech, such as modern automotive leak testing equipment designed for precision and efficiency.

How Leak Testing Actually Works Today

A. Tracer Gas Testing: The Gold Standard

Let’s talk about helium. It’s perfect for leak detection, non-reactive, tiny, and easy to track.

Here are some of the most effective ways to use it:

- Helium Mass Spectrometry: Detects leak rates as low as 1 x 10⁻⁹ mbar·l/s. Super sensitive. Super reliable. Used for everything from fuel systems to medical devices.

- Vacuum Chamber Testing: Stick the part in a vacuum chamber, introduce helium, and watch for any escaping gas. It’s a 360-degree scan.

- Accumulation Testing: Useful for big or weirdly shaped parts. Helium builds up in a chamber and a sensor measures how much escaped.

- Sniff Testing: A technician uses a handheld device to literally sniff out leaks around the component.

- Spray Testing: Spray helium over a part and see if any gets inside, great for checking welds and seams.

- Forming Gas (Hydrogen-Nitrogen blend): A cheaper, greener alternative to helium. With just 5% hydrogen, it’s safe and still sensitive.

B. Pressure-Based Testing: For Simpler Jobs

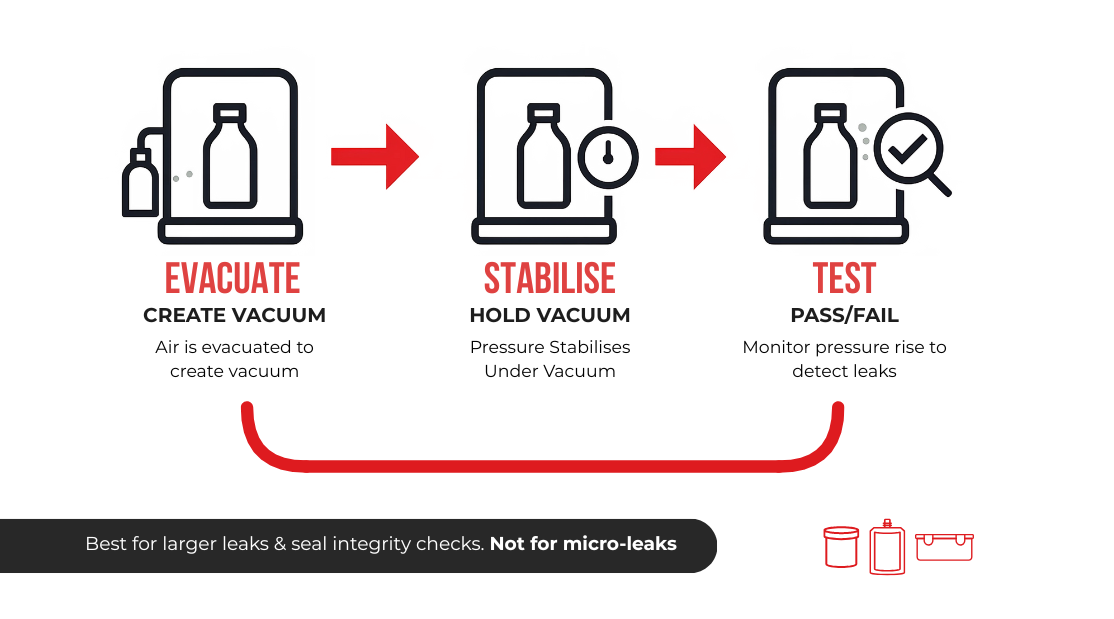

- Pressure Decay: Pressurise the part, wait, and watch for pressure drops. Simple but not the most sensitive.

- Vacuum Decay: Evacuate the part and see if the pressure rises. Slightly better than pressure decay, but still limited in sensitivity.

These are good for catching big leaks or as a pre-screen before more accurate testing.

Efficiency Matters: Using Less Gas, Saving More Money

Helium Shortages Are Real

Helium isn’t endless. It’s mostly a byproduct of natural gas, so supply is shaky and prices fluctuate wildly. Just venting used helium? That’s like burning money.

Smarter Helium Strategies

- Helium Recovery Systems: Systems like PURE can reclaim and purify helium to 90–99% purity, slashing costs by up to 90%.

- Use Less, Test Smart: Tweak things like gas concentration and cycle time. Use only what’s needed.

- OptVol Tech: Reduces energy use by up to 92%, cuts helium use by 44%, and takes up less space. Especially handy for fuel cell testing.

Automation + Data = Leak Testing 2.0

Consistency Without Compromise

Machines don’t get tired. Automated systems ensure every test is done the same way, every time—minimizing human error.

Seamless Factory Integration

Modern test systems slot right into existing lines, complete with rotary tables, conveyors, and even cobots (collaborative robots). That means higher throughput and less manual labour.

Let the Data Speak

- Real-Time Feedback: Instantly see what’s working and what’s not.

- Traceability: Every test is logged with part numbers, operator IDs, and timestamps. Perfect for audits.

- Predictive Maintenance: Spot subtle shifts in performance before they cause downtime.

Meeting the Standards, Every Time

Regulations aren’t optional. Here’s what’s being followed worldwide:

- Europe: PED & PE(S)R

- South Korea: KGS

- Japan: KHK

- US: ASME BPVC

- China: SELO

- Hydrogen Standards:

- R134: Covers everything from tank components to fire testing.

- TCATSI 02 007-2020: Focuses on safe, sealed, high-pressure hydrogen cylinders.

CPK: The Quality Benchmark

A CPK > 1.67? That’s the gold standard. It means the process consistently hits the mark with minimal variation.

Documentation = Confidence

Test plans, calibration records, results logs—it’s all tracked, traceable, and ready for inspection. A well-documented test process isn’t just about compliance, it’s about confidence.

Planning for Growth: Scaling Up Without Slowing Down

As hydrogen mobility and EV demand grow, leak testing has to scale with it.

Avoid Bottlenecks

Systems built for small batches can’t keep up with high-volume production. Delays, errors, and helium costs explode.

Think Ahead

- Modular Systems: Easy to expand as demand grows.

- Turnkey Solutions: Everything works together, hardware, software, and automation.

Be Infrastructure Ready

More testing means more gas, more power, more training. Make sure your facility and your team can handle it.

Wrapping It Up: Leak-Free is the Future

Leak testing might not be glamorous, but it’s essential—especially with today’s high-pressure, high-tech vehicle systems. From fuel cells to batteries, automotive leak testing equipment ensures safety, efficiency, and peace of mind.

The takeaway? If you’re in automotive design, engineering, or manufacturing, it’s time to revisit your leak testing strategy. Smarter tools, better data, and automated systems can make all the difference, not just for today’s production, but tomorrow’s innovation.