Investing in a leak test system is likely going to be a CapEx decision. Whether it is part of a new production line or a replacement for an ageing setup, the system you choose will play a central role in your operation. It will be relied on every day to deliver accurate, repeatable results and to integrate smoothly into your existing processes. More than that, it needs to support your team, your compliance goals, and your production targets.

We have worked with manufacturers at every stage of this journey. Some arrive with a clear idea of what they need. Others are still exploring what is possible. In both cases, asking the right questions early on leads to stronger decisions and better outcomes. These four are a good place to start.

1. What are you testing and how might that change?

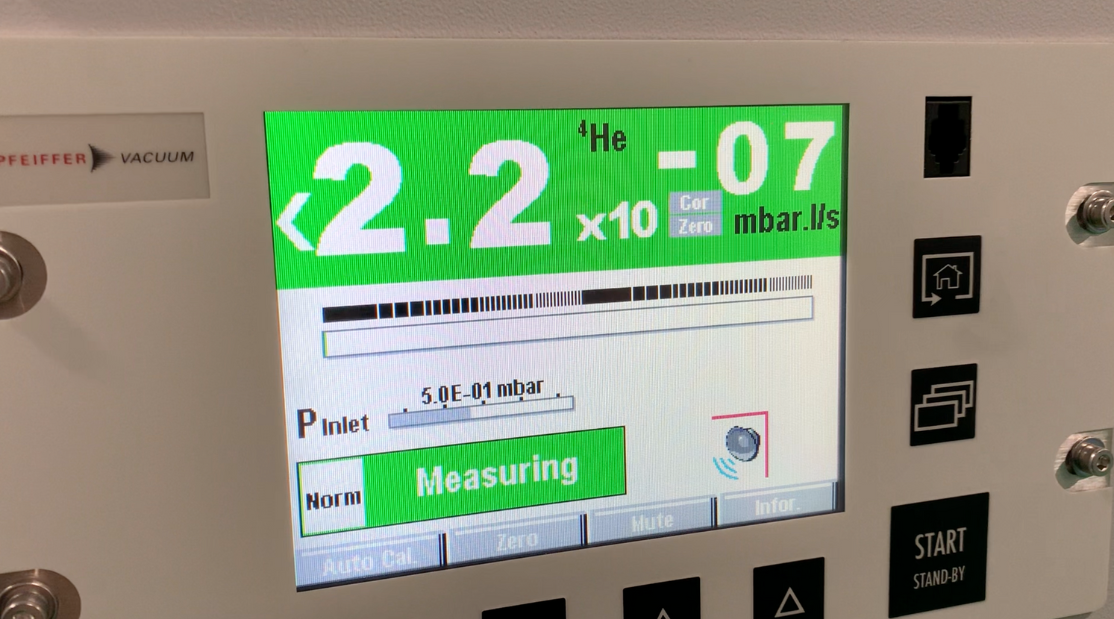

Begin with the product. Are you testing high-pressure hydrogen tanks, battery modules, HVAC components, or something else entirely? What are the pressure requirements? What leak rate is acceptable? Are there specific standards or regulations that must be met?

Just as important as your current needs are the changes that may come later. Are you expecting to add new product variants? Will your volumes grow? Could your target market require you to comply with different standards in the future?

The best leak test systems are designed with flexibility in mind. Look for systems that offer configurable tooling, adjustable test parameters, and software that can adapt as your needs evolve. This way, you are not locked into a solution that only serves you today.

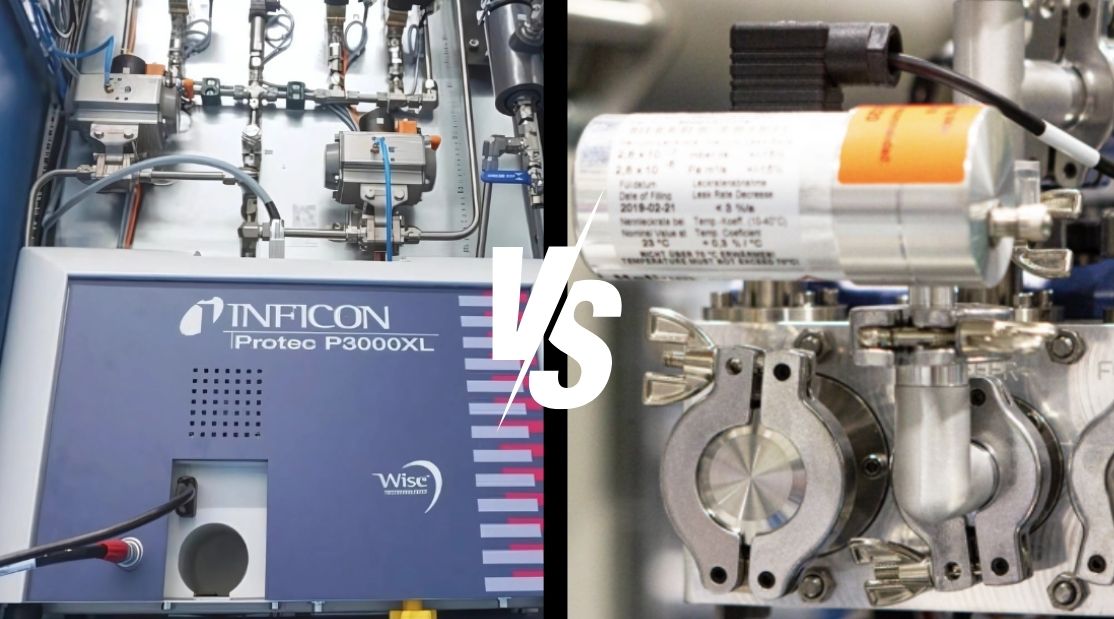

2. How much automation do you really need?

There is a wide spectrum of automation available. Some manufacturers benefit from fully automated systems that handle everything from part loading to result logging. Others prefer a semi-automated approach that gives operators more control. What works best depends on your production environment, your staffing levels, and the complexity of your testing process.

Consider the entire workflow. Do you need automatic clamping or part identification? Will the system need to route pass and fail parts differently? Is it important to log test data for every part, and if so, how should that data be stored and accessed?

Automation can be a huge benefit, but only if it serves a clear purpose. Make sure each automated feature supports a goal, whether that is improving consistency, increasing throughput, or reducing operator involvement.

3. What kind of support will you need after installation?

A leak test system is a long-term investment, and its value depends on how well it performs over time. Maintenance and support are key to keeping performance consistent and downtime to a minimum.

Before you commit, ask how the system will be supported. Is your team expected to handle routine servicing, or will you have access to on-site support? How quickly can spare parts be delivered? Are service engineers available when needed, and is remote support an option?

The answers will help you decide whether the system fits your internal capabilities. A reliable support plan is just as important as the hardware itself, especially when unplanned downtime can disrupt production.

4. What does success look like for your team?

Finally, take a step back and define success. What are you hoping this system will deliver? For some companies, it is all about precision and meeting tight leak rate requirements. For others, it is speed, flexibility, or cost efficiency. Some are preparing for audits and need full traceability, while others are aiming to cut helium usage and reduce environmental impact.

When you are clear about what matters most to your business, it becomes easier to evaluate different options. Every feature, every capability, should support the outcomes that are most important to you.

A smarter way to begin

Choosing a leak test system is not just a technical decision. It is about finding the right fit for your process, your team, and your future plans. At VES, we believe that asking better questions upfront leads to fewer compromises later on. If you are just starting your research or need help reviewing your current setup, we are here to support you with practical guidance based on years of real-world experience.