As the world transitions to sustainable energy sources, hydrogen has become a key component in the green energy movement. However, storing hydrogen at high pressures poses substantial challenges, especially in maintaining the integrity and safety of storage systems. Robust leak testing is vital for the reliability and safety of high-pressure hydrogen storage systems. VES New Energies offers a solution that meets the stringent R134 standard and provides the capability to test pressures up to 875 bar.

The Importance of Leak Testing in Hydrogen Storage

Hydrogen, as a highly flammable gas, poses unique safety challenges. The integrity of hydrogen storage systems is essential to prevent leaks that could lead to catastrophic failures. Leak testing ensures that storage vessels can withstand the high pressures required to store hydrogen safely and efficiently. According to the Economic Commission for Europe Regulation No. 134, leak testing is essential for the approval of motor vehicles and their components with regard to the safety-related performance of hydrogen-fuelled vehicles (HFCVs).

High-pressure hydrogen storage systems must be tested rigorously to ensure they do not leak. Leaks can lead to explosions or fires, particularly in enclosed or semi-enclosed spaces. Therefore, testing these systems under the maximum allowable working pressure (MAWP) and maximum fuelling pressure (MFP) is necessary. Regulation No. 134 specifies that the MAWP is the highest gauge pressure to which a storage system is permitted to operate under normal conditions, while the MFP is the maximum pressure applied during fuelling, typically 125% of the nominal working pressure (NWP).

Key Features and Benefits of Compliant Systems

- High-Pressure Testing Capability

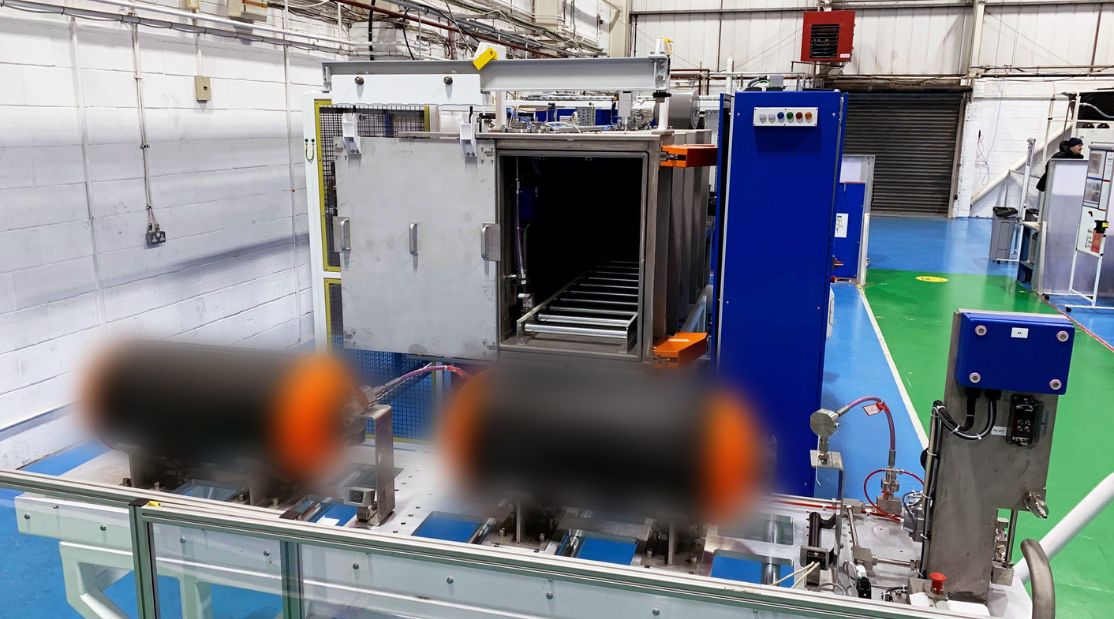

A compliant leak testing system must be capable of testing pressures up to 875 bar. This high-pressure testing ensures that hydrogen storage vessels can safely contain hydrogen at the pressures required for various applications, including automotive and industrial uses. Such capabilities are essential for validating the structural integrity and safety of storage systems under real-world conditions. VES New Energies’ system excels in this area, providing robust performance at extremely high pressures, which is necessary for ensuring the safety and reliability of hydrogen storage solutions. - Modular and Flexible Design

The modular design of advanced leak testing systems allows for customisation to meet specific production needs. This flexibility is particularly important as the hydrogen industry evolves and production demands change. Manufacturers can add modules as needed, ensuring that the system can grow with their requirements without the need for significant additional investments. This adaptability helps manufacturers optimise their operations and manage costs effectively. - Turnkey Solutions

Comprehensive turnkey solutions streamline the leak testing process by integrating seamlessly into production lines. From loading to unloading, these systems handle all aspects of the leak testing process, simplifying operations and reducing the need for multiple suppliers. This integration ensures efficient workflows and consistent testing standards across the entire production line. - Compliance with Global Standards

Leak testing systems that meet both R134 and TCATSI standards ensure global compliance. This certification provides manufacturers with the confidence that their products meet international safety and performance standards, facilitating market entry and acceptance. Compliance with these standards is crucial for accessing global markets and meeting regulatory requirements in different regions. - Advanced Leak Detection Methods

Using advanced gases and proven methodologies, modern leak testing systems offer highly accurate and traceable leak detection. This precision is essential in ensuring the safety and reliability of hydrogen storage vessels, minimising the risk of leaks and enhancing overall safety. Accurate leak detection also helps in maintaining the performance and longevity of hydrogen storage systems.

The Significance of the R134 Standard

The R134 standard, established by the Economic Commission for Europe, outlines the requirements for the safety-related performance of hydrogen-fuelled vehicles. This standard is comprehensive, covering various aspects of hydrogen storage systems, including design, testing, and operational procedures. Complying with this standard ensures that hydrogen storage systems are robust and reliable, capable of withstanding the demanding conditions they will encounter in real-world applications.

Advanced Leak Detection Methods

Robust leak testing is essential for the safe and reliable operation of high-pressure hydrogen storage systems. By ensuring the integrity and safety of these vessels, manufacturers can prevent potentially catastrophic failures and support the broader adoption of hydrogen as a sustainable energy source. VES New Energies offers a solution that meets the stringent R134 standard, providing precision and reliability in leak detection, and playing a critical role in the global shift towards sustainable energy.

Contact us today to learn more about how we can help you ensure the safety and compliance of your hydrogen storage solutions.