Helium has long been the go-to tracer gas for leak testing, and for good reason. It’s inert, safe to use, and incredibly sensitive, able to detect even the smallest leaks that other methods might miss. But as helium becomes more expensive and less readily available, manufacturers are facing a tough challenge: how to reduce helium usage without compromising the accuracy and reliability of their tests.

The good news is that saving helium doesn’t have to mean sacrificing performance. With the right approach, it’s entirely possible to maintain high standards in leak detection while using far less helium than before.

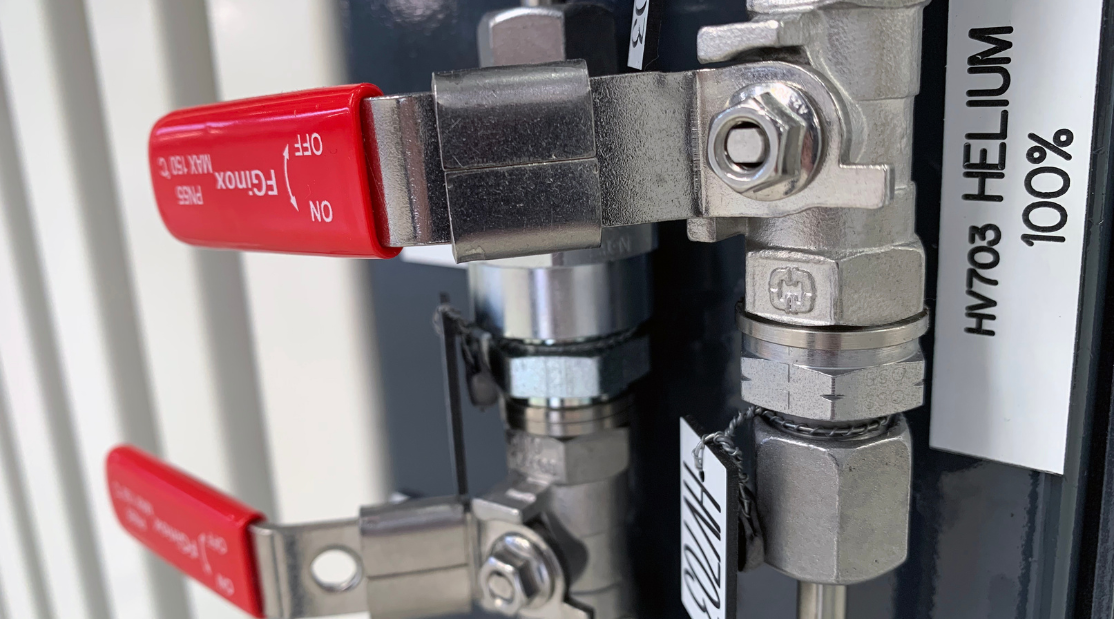

Rethinking Helium Concentration

One of the simplest ways to cut helium usage is by switching from 100 percent helium to a helium nitrogen mix. For many applications, using a blend like five percent helium in nitrogen still provides the sensitivity needed to detect acceptable leak rates, especially when systems are calibrated to work with lower concentrations.

This adjustment might require a bit of fine-tuning, particularly around sensor settings and background noise management, but it’s a proven method that can significantly reduce consumption. And when you consider how much helium is used in a busy production environment, the savings add up quickly.

Capturing What You Already Have

Another highly effective strategy is helium recovery. Rather than letting the gas escape into the atmosphere after each test, recovery systems collect it, purify it, and feed it back into the test cycle. It’s a smart, sustainable solution, especially in facilities where helium is used continuously.

Modern recovery units can handle both pure helium and mixed gases, and they’re capable of restoring helium to high levels of purity. That means you’re not just saving helium, you’re reusing it efficiently without affecting the sensitivity of your tests.

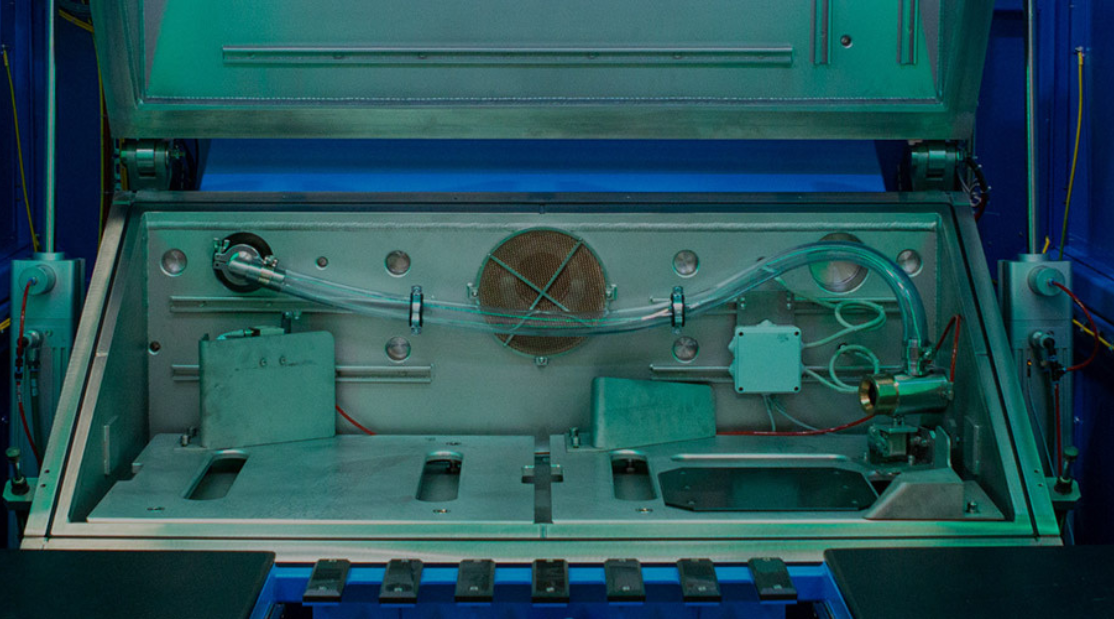

Designing for Efficiency

Sometimes, the biggest savings come from the design of the test system itself. Equipment that’s built with efficiency in mind can make a massive difference. Smaller, well-sealed enclosures, for instance, require less helium to fill. And systems with smart valve timing and minimal dead space help ensure helium is only used when and where it’s needed.

Even reducing the length of tubing or improving how gas is routed through the system can impact how much helium is used per cycle. It’s often these small design details that create the biggest improvements in overall efficiency.

Getting the Team on Board

It’s also important to remember the human element. In manual testing methods like spray or sniff testing, the operator plays a huge role in how much helium gets used. Without clear guidance, it’s easy to overapply or waste gas without realising it.

Training and standardised procedures are key. When operators know exactly how much helium to use, where to apply it, and how to do it consistently, efficiency improves dramatically. And in some cases, semi-automated systems can take over the most repetitive tasks, ensuring uniform results and reducing variability.

Letting the Data Lead the Way

Tracking and analysing how helium is used across the production line gives you the visibility needed to make informed decisions. Look at test cycle times, gas usage per part, and overall consumption trends. If something looks off like a sudden spike in helium use or inconsistent test results it’s a sign that something in the process might need attention.

Using data in this way not only helps you save helium, it also strengthens the overall reliability of your testing operation. It becomes easier to spot inefficiencies, predict maintenance needs, and make targeted improvements where they’ll have the most impact.

Helium may still be the benchmark for high-sensitivity leak testing, but that doesn’t mean it has to be used wastefully. With a bit of planning, smart system design, and attention to detail, it’s entirely possible to bring down helium consumption without compromising the quality of your results.

VES works with manufacturers every day to make this balance a reality. Whether you’re just starting to think about helium savings or looking to optimise an existing setup, we’re here to help you find the most effective path forward.