How do you determine the most appropriate leak test method for your manufacturing needs? At VES, we know that choosing the right method is essential for ensuring the integrity and performance of your products. With so many methods available, it can be challenging to decide which one is the best fit for your specific application. In this article, we’ll explore key considerations that manufacturers should keep in mind when selecting a leak test method, drawing on our extensive experience and expertise in the field.

The Basics of Leak Testing

Leak testing is a non-destructive testing method used to detect and quantify leakage in sealed systems and components. The goal is to ensure that the product meets specified leak-tightness requirements, thereby guaranteeing its reliability and safety. Several methods are employed in the industry, each with its own advantages and limitations. The main methods include:

- Ultrasonic measurement

- Bubble test

- Pressure decay

- Vacuum decay or pressure rise test

- Helium sniff

- Helium spray

- Helium accumulation

- Helium leak detection through vacuum systems

Key Considerations for Selecting a Leak Test Method

- Sensitivity Requirements

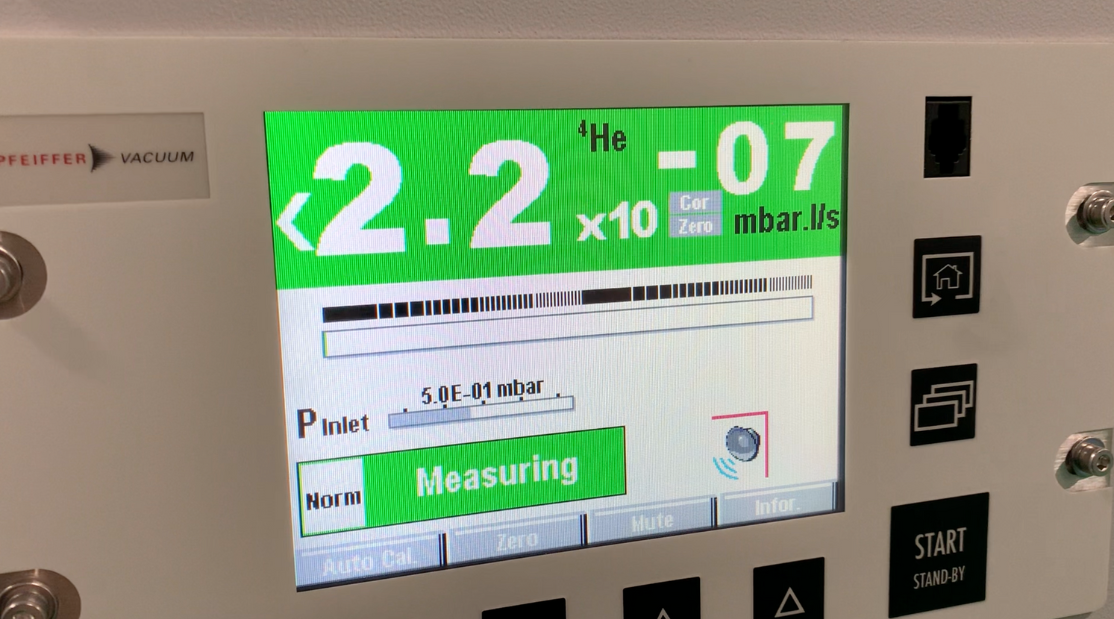

The sensitivity of a leak test method is a major factor to consider. Sensitivity refers to the smallest leak rate that the test can reliably detect. For instance, helium leak detection through vacuum systems offers very high sensitivity (down to 10^-8 mbar·litre/sec), making it ideal for applications where detecting even the smallest leaks is essential. On the other hand, methods like the bubble test have lower sensitivity and may not be suitable for fine leak detection.

- Type of Product and Leak Location

The physical characteristics of the product and the location of potential leaks also influence the choice of the leak test method. For example, ultrasonic measurement is suitable for detecting large leaks but is less effective for complex systems with multiple leak points or high background noise. Helium sniffing and spraying methods are effective for pinpointing the exact location of leaks, but they are operator-dependent and less suitable for automated processes.

- Environmental Conditions

Environmental factors such as temperature and humidity can affect the accuracy and reliability of certain leak test methods. Pressure decay tests are particularly susceptible to temperature changes, which can cause false readings. In contrast, vacuum decay tests are less affected by temperature variations, making them more reliable under fluctuating environmental conditions.

- Production Throughput

The required production throughput will significantly impact the choice of a leak test method. Automated systems like helium accumulation or vacuum systems can provide high throughput and repeatable results, making them suitable for large-scale manufacturing. Manual methods, such as the bubble test and helium sniffing, are more labour-intensive and may result in lower throughput and higher operational costs.

- Test Cycle Time

Test cycle time is another important consideration, especially for high-volume production lines. Methods that require long stabilisation times, such as pressure decay tests, may not be suitable for applications with strict time constraints. Helium-based methods, while providing high sensitivity, may also require longer test cycles. Balancing sensitivity and cycle time is crucial for optimising production efficiency.

- Safety Concerns

Safety is always a priority in manufacturing environments. Certain leak test methods, such as helium sniffing, can pose safety risks if the component is charged at high pressures. It is essential to choose a method that ensures the safety of operators and minimises potential hazards. Helium vacuum systems, while more expensive, offer high sensitivity and can be automated to reduce operator involvement and enhance safety.

- Cost Considerations

Budget constraints will inevitably influence the choice of a leak test method. While some methods like the bubble test and pressure decay are relatively inexpensive, they may not provide the required sensitivity or throughput for all applications. Helium-based methods and vacuum systems, although more costly, offer higher sensitivity and can be more cost-effective in the long run due to their reliability and potential for automation.

- Specific Application Requirements

Each application may have unique requirements that influence the choice of a leak test method. For example, products that operate under high pressures may benefit from vacuum decay tests, which apply pressure in the opposite direction to simulate operating conditions. Similarly, brazed products, which can be tested immediately after exiting the furnace using helium accumulation methods, benefit from the method’s insensitivity to temperature variations.

Choosing the Correct Method

Selecting the best leak test method requires a careful evaluation of various factors, including sensitivity requirements, product characteristics, environmental conditions, production throughput, test cycle time, safety concerns, and budget constraints. At VES, we leverage our extensive expertise to help manufacturers choose the most appropriate leak test method for their specific needs. Our goal is to provide reliable and efficient solutions that enhance product quality and performance while meeting sustainability goals. Contact us today to learn more about our comprehensive range of leak testing services and how we can support your manufacturing processes.