One of the biggest questions manufacturers face, do I upgrade my existing leak detection system or replace it entirely. It’s a decision that has both short-term and long-term consequences, for cost, reliability, safety, and compliance. And while there’s no one-size-fits-all answer, there are clear factors that can help point you in the right direction.

Leak testing systems play an essential role in maintaining product integrity, especially in high-pressure applications like hydrogen tanks or battery modules. But even well-built systems reach a point where improvements are needed. The challenge is knowing when an upgrade is enough and when a full replacement is the better investment.

Understanding the Starting Point

The first step is a simple one: assess how your current system is performing. Are you still meeting your cycle time targets? Have your test failures increased? Is the system still fit for the products you’re testing today or the ones you’ll be testing next year?

These questions can highlight where the real pressure points are. Often, the issue isn’t the system itself, but how well it aligns with today’s requirements.

When Retrofitting Makes Sense

Retrofitting can be a smart move when the core mechanics of your system are still in good condition. A focused upgrade can restore performance, extend equipment life, and avoid the cost and downtime of a full replacement.

Here are a few situations where retrofitting is the better option:

You’re seeing minor inefficiencies or drift.

Replacing key components such as valves, sensors, or controllers can bring the system back to its original speed and accuracy.

You need to adapt to small product changes.

New tooling, modified fixturing, or updated test recipes can often be integrated without changing the main system.

Helium usage is becoming costly.

Adding a helium recovery system or transitioning to forming gas can lower costs without altering your test architecture.

You’re trying to minimise downtime.

Retrofitting can often be done in stages or during planned shutdowns, helping you stay operational while upgrading.

These types of changes can have a big impact without requiring a full restart. Many companies find they get several more years of reliable service with the right upgrades.

When It’s Time to Replace

In other cases, holding on to ageing equipment starts to cost more than it saves. If your system is struggling to keep pace with production demands, or if support and parts availability are becoming a challenge, a new system might be the better long-term decision.

Here are signs that replacement should be seriously considered:

Throughput is no longer meeting your targets.

If your system can’t keep up with higher volumes or faster line speeds, replacing it may be the only way to avoid bottlenecks.

The equipment is no longer supported.

Outdated controls, obsolete parts, or discontinued components can make servicing the system costly and inconsistent.

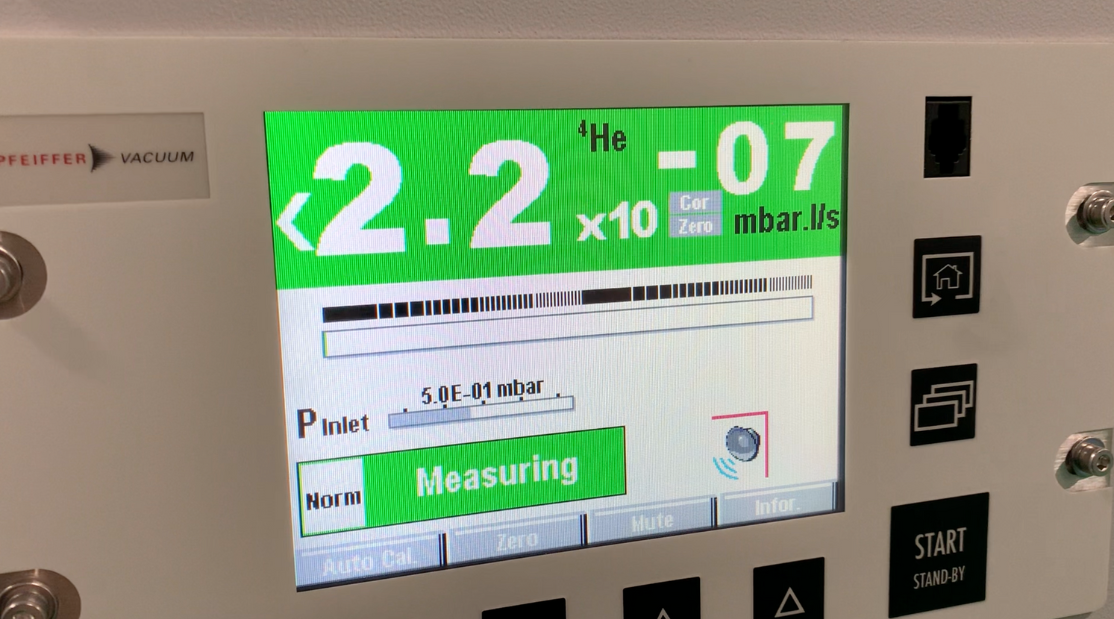

Test results are no longer reliable.

Increased false fails, leaks missed during testing, or inconsistent pressure control are all indicators that the system may no longer be trustworthy.

Regulatory compliance is becoming harder.

As standards evolve, your current system may not be able to meet new leak rate requirements or documentation expectations.

Product types have changed dramatically.

A system built for fuel tanks may not be suitable for 900 bar hydrogen vessels. In these cases, a new approach and new technology is often required.

New systems can also offer benefits that weren’t available when your current equipment was installed: better automation, smarter data capture, reduced footprint, or modular expansion.

How to Decide

The best approach is to compare the total cost of both options. Factor in not just the upfront cost of replacement, but also the cost of ongoing maintenance, potential downtime, and the impact of slower or inconsistent testing.

You’ll also want to look ahead. Will your product range expand? Will compliance become more demanding? Will automation or energy savings be more important next year than they are today?

A detailed equipment audit is often the best way to weigh your options. From there, the decision becomes less about guesswork and more about strategy.

Small Adjustments, Big Impact

Whether you’re considering an upgrade or thinking about a new system altogether, the goal remains the same: reliable, repeatable, and efficient testing that meets your current and future needs. VES supports customers with both retrofit and replacement solutions, helping you make the most informed choice for your production line. If you’re evaluating your next steps, our team is ready to help you explore every option.