It’s easy to get caught up in the daily pace of production, focusing on cycle times, meeting throughput targets, and keeping parts moving. But in the middle of all that activity, the routine safety checks can sometimes be overlooked. The reality is, they are essential. The environments we work in involve high pressure, flammable gases, and sensitive components, which means there is very little room for error.

Some of the most serious issues we’ve encountered over the years haven’t come from major failures, but from small details that were missed. A worn seal, a stuck valve, or a faulty vent can all lead to larger problems. That’s why it’s so important to take the time to make sure the fundamental safety checks are completed properly and consistently.

1. Check the Condition of Seals and Clamps

This should be one of the first checks carried out at the start of every shift. Seals and clamps are often under constant stress, and even the slightest wear or deformation can compromise both test accuracy and operator safety. When testing under pressure, a poor seal is more than just a potential test fail, it can be the point of a dangerous release.

Make it standard practice to inspect all sealing surfaces for signs of wear, hardening, cracking, or misalignment. Pay close attention to quick-change tooling and fixtures, especially if your line handles multiple product variants throughout the day. If something looks questionable, change it. It’s a low-cost precaution that can prevent high-cost incidents.

2. Confirm Emergency Stop Functions and Pressure Isolation

Emergency stops and pressure isolation valves are the last line of defence when something goes wrong. The problem is that they’re rarely used and because of that, they’re rarely tested. Make a habit of verifying that all emergency stop buttons, pressure vent valves, and interlocks are fully functional. This includes checking that pressing the E-stop actually vents the system and halts all test activity.

Operators should know exactly where these controls are, what they do, and when to use them. It’s not enough to assume the system is safe just because it was last week. Confirm it, regularly.

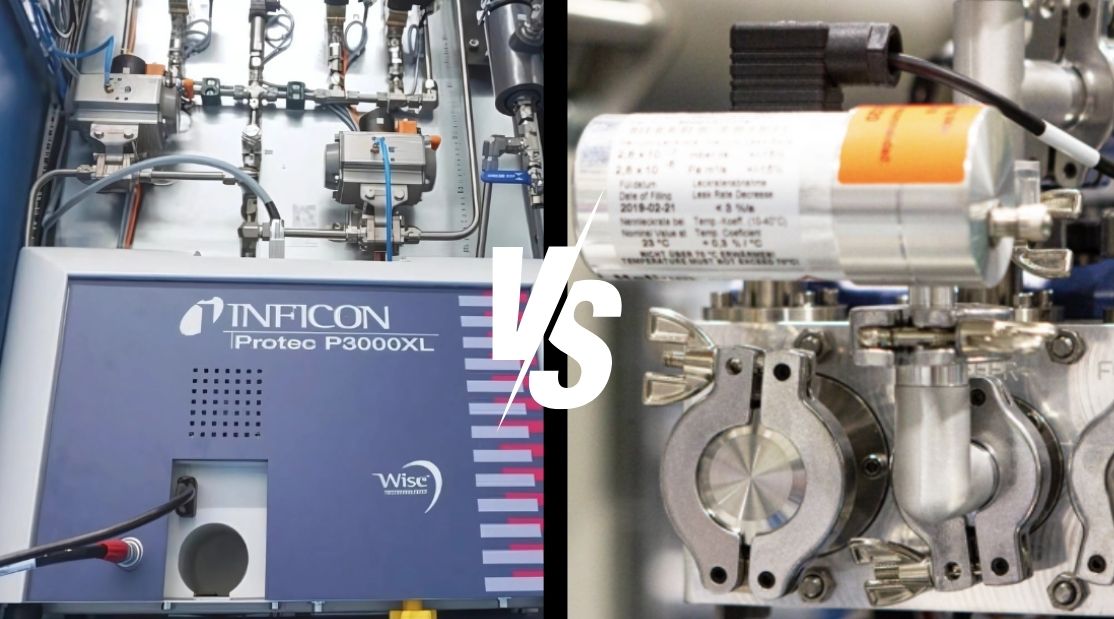

3. Inspect Gas Supply Connections and Venting Lines

Test systems using helium, hydrogen, or forming gas rely on a network of supply lines, regulators, and valves to deliver and control gas flow. These components are often tucked away and easy to overlook, but they’re critical to maintaining a safe working environment.

Look for cracked hoses, loose fittings, or signs of wear on regulator connections. Ensure all supply lines are properly rated for the pressure they’re handling, and that there is no evidence of leaks. Gas leaks can be quiet and odourless, particularly with hydrogen, so detection systems must be in working order and calibrated regularly.

Equally important is the venting system. If a test gas cannot vent quickly and cleanly at the end of the cycle, pressure can build up unexpectedly. Check that vent lines are clear, correctly routed, and securely connected, especially after maintenance or part changes.

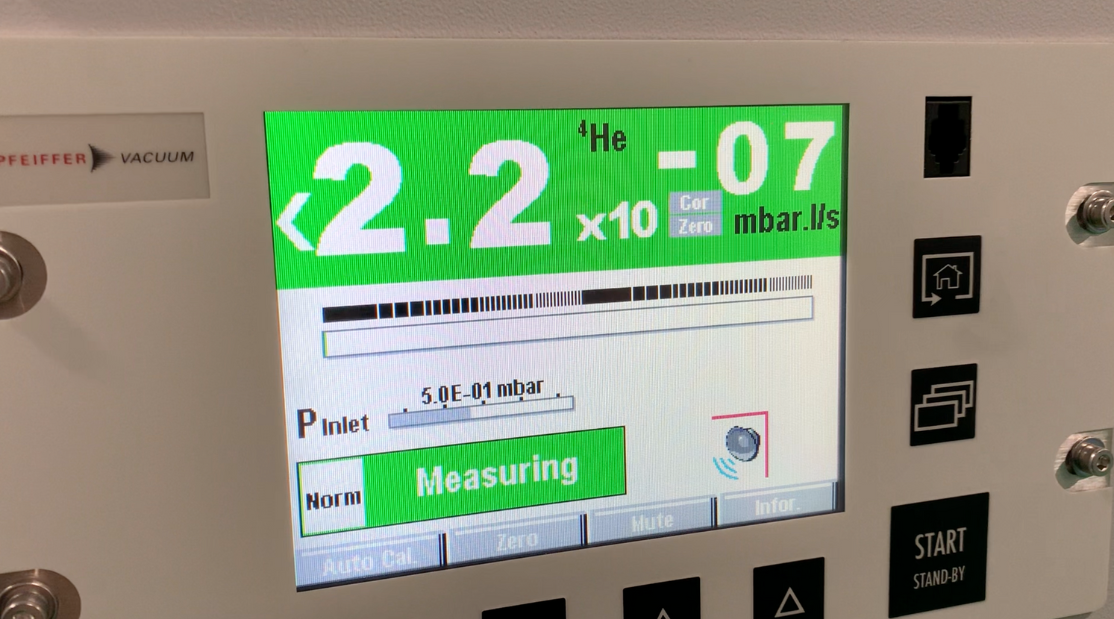

4. Review Pressure Build-Up and Stabilisation Behaviour

Many systems will give you cycle data showing how pressure builds and holds during each test. Take advantage of this. A slow rise or unstable hold can be an early sign of valve fatigue, sensor drift, or internal leaks. If the pressure curve looks different from the baseline or takes longer to stabilise, don’t ignore it.

Set threshold alarms if your system allows it, and schedule a weekly review of the data. This type of preventative check helps catch issues before they affect both safety and test reliability.

5. Keep the Test Area Clear and Operators Prepared

Finally, a clean and well-organised test area is an important safety measure in itself. Tripping hazards, tangled cables, and poor access to emergency controls all increase the risk of an incident. Make sure that operators have a clear path to walk, room to work, and easy access to protective gear.

Training should be refreshed regularly. Don’t wait until someone new joins the team. Use team meetings to revisit safety basics, share lessons learned, and reinforce the importance of reporting anything that doesn’t look or feel right.

Small Checks That Make a Big Difference

None of these safety checks are particularly time-consuming. But the impact of skipping them, even just once can be serious. The goal is to create habits that are automatic, not reactive. When safety becomes part of the daily routine, it protects not just people, but production, reputation, and peace of mind.

At VES, we’ve designed our systems to be safe, reliable, and serviceable, but no machine is safer than the people operating it. If you’d like help developing a tailored safety checklist for your specific application, or want support training your team on best practices, we’re here to support you.