What makes helium sniff testing the preferred choice for leak detection in so many industries today? At VES, we’ve witnessed how manufacturing standards have evolved, with companies now demanding greater precision and reliability from their processes. As traditional leak detection methods struggle to keep up, helium sniff testing has stepped in to fill the gap, offering unmatched accuracy and versatility. It’s not just a technological upgrade—it’s a necessity for manufacturers striving to meet the demands of modern production.

The Basics of Helium Sniff Testing

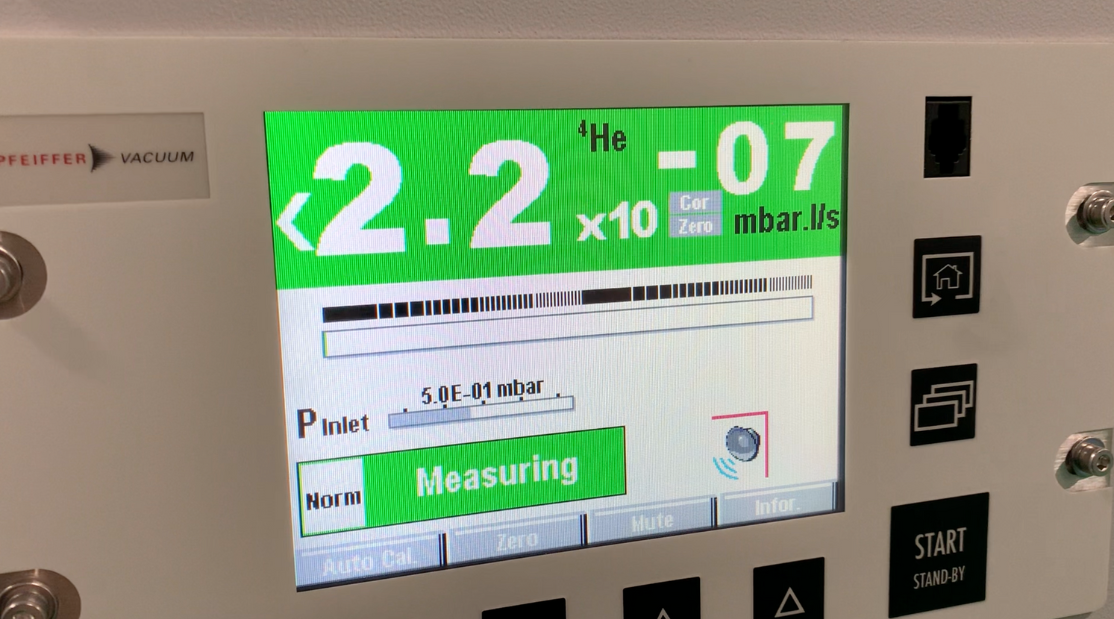

Helium sniff testing is a process used to detect leaks in sealed systems or components. It involves pressurising the part with a helium-rich gas and using a sensitive sniffing probe to detect any helium escaping through potential leak points. Unlike other methods, sniff testing pinpoints the exact location of a leak, making it ideal for applications where precision is critical.

The helium molecules, being incredibly small and light, can escape through the tiniest defects, making this process highly effective for detecting even microscopic leaks. The result? A level of sensitivity that other methods, like air pressure or bubble testing, simply can’t match.

Why Manufacturers are Making the Switch

As industries face increasing demands for quality and safety, helium sniff testing offers a range of advantages that traditional methods can’t compete with.

- Pinpoint Precision

In sectors like automotive, aerospace, and electronics, even the smallest leak can lead to catastrophic failures. Helium sniff testing allows manufacturers to locate and measure leaks with exceptional accuracy, ensuring components meet exacting standards. For example, in the production of fuel systems or HVAC components, this precision is essential to maintaining product integrity. - Enhanced Product Reliability

Modern consumers expect products to last longer and perform better. Helium sniff testing helps ensure the reliability of components by detecting flaws before they become larger issues. This proactive approach reduces warranty claims, enhances customer satisfaction, and protects brand reputation. - Versatility Across Applications

From small electronics to large industrial systems, helium sniff testing is adaptable to a wide range of applications. It’s particularly valuable in scenarios where other methods might struggle, such as testing complex geometries, intricate seals, or hard-to-access areas. - Sustainability and Resource Management

As businesses place more emphasis on sustainability, helium sniff testing provides an edge. By incorporating helium recovery systems, manufacturers can minimise waste, lower costs, and reduce their environmental impact.

Industries Leading the Charge

Several industries have already embraced helium sniff testing as a core part of their production process:

- Automotive: Detecting leaks in fuel systems, air conditioning units, and engine components ensures vehicle safety and performance.

- Aerospace: With safety as a non-negotiable priority, sniff testing is used for hydraulic systems, fuel lines, and pressurized cabins.

- Electronics: Hermetically sealed devices rely on sniff testing to maintain airtight integrity, protecting delicate components from external factors.

- HVAC: Sniff testing ensures leak-free performance in refrigeration and air conditioning systems, preventing costly inefficiencies.

The Challenges and How to Overcome Them

While helium sniff testing offers unmatched benefits, it’s not without its challenges. The process can be time-consuming for large components with many potential leak points, and the initial investment in equipment may deter smaller manufacturers. However, advances in sniffing technology and recovery systems are making the process faster, more affordable, and easier to implement across different scales of operation.

For businesses on the fence, the long-term savings and improved product quality often outweigh the upfront costs.

The Future of Helium Sniff Testing

As manufacturing continues to evolve, helium sniff testing is poised to play an even greater role. Advances in sensor technology, automation, and recovery systems are making the process faster and more efficient, further cementing its place as the standard for leak detection.

The push for sustainability will also drive adoption. With manufacturers under increasing pressure to minimise waste and reduce emissions, helium sniff testing aligns perfectly with these goals. By ensuring products are leak-free, companies can improve energy efficiency and reduce the environmental impact of their operations.

Innovating for the Future

At VES, we’ve spent decades developing and perfecting leak detection solutions for industries worldwide. Helium sniff testing has emerged as one of the most effective and reliable methods for ensuring product quality and safety. Its precision, adaptability, and alignment with modern manufacturing priorities make it an invaluable tool for companies looking to stay ahead of the curve.