What if the key to a sustainable transportation future lies in hydrogen? As the world accelerates its shift toward clean and sustainable energy, hydrogen is becoming a necessary component in the mobility sector. The hydrogen mobility market is poised for substantial growth, driven by technological advancements and strong regulatory support for green energy initiatives. With this surge in demand, there is a pressing need for advanced hydrogen storage solutions that ensure safety and compliance with stringent regulations. VES New Energies is leading this transformation, offering modular and scalable leak-testing systems that are designed to future-proof hydrogen storage production and meet the industry’s needs.

The Hydrogen Mobility Market: A Growing Force

The global hydrogen mobility market is expected to expand rapidly over the next decade. According to industry forecasts, the market for hydrogen fuel cell vehicles (HFCVs) is projected to grow significantly, driven by factors such as the global push for decarbonisation, advancements in hydrogen fuel cell technology, and government incentives for green energy solutions. Countries like Japan, South Korea, and Germany are leading the way with substantial investments in hydrogen infrastructure and research, creating a robust market for hydrogen-powered vehicles.

The adoption of hydrogen fuel cells in various modes of transport—ranging from passenger cars to heavy-duty trucks, buses, and even trains and ships—is set to transform the transportation landscape. This shift is not only beneficial for the environment but also offers energy security and diversification of energy sources. However, this growth also necessitates the development of efficient and reliable hydrogen storage solutions.

Hydrogen Storage Technology: Meeting the Challenge

As the demand for hydrogen fuel cell vehicles grows, so does the need for effective hydrogen storage solutions. Hydrogen, being the lightest and smallest molecule, poses unique challenges in terms of storage and leak detection. Ensuring the safety and integrity of hydrogen storage systems is paramount, particularly under high-pressure conditions.

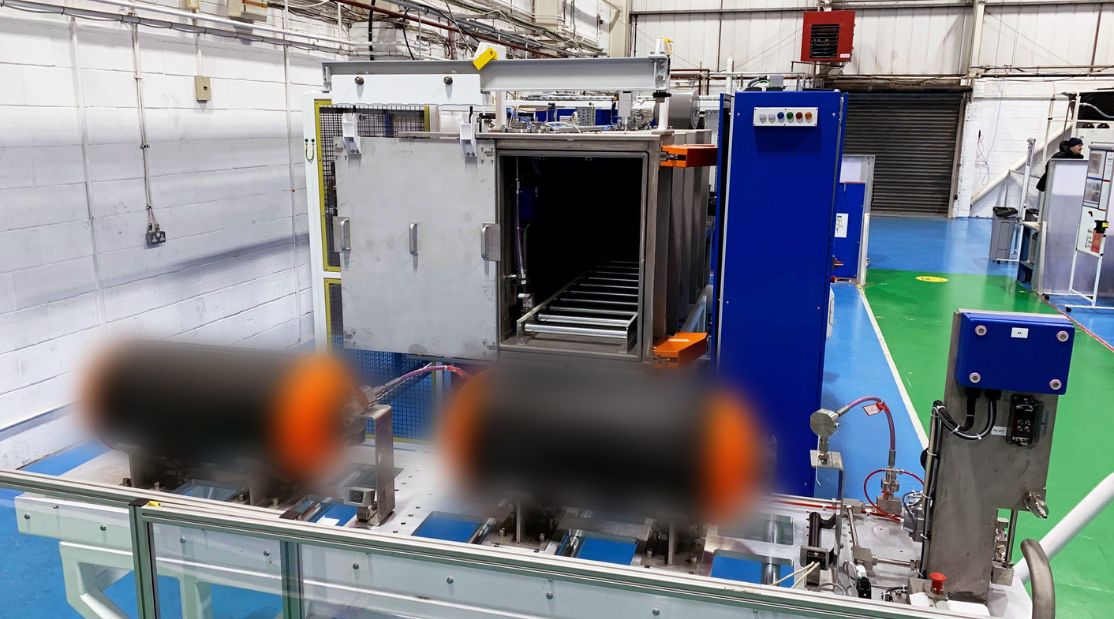

We have developed leak-testing systems that cater to these needs. Our systems are designed to comply with international standards such as the R134 and TCATSI 02 007-2020, ensuring that hydrogen storage solutions meet stringent safety and performance criteria.

Key Features of VES New Energies Leak Testing Systems:

- Modular and Scalable Design: Our leak-testing systems are modular and scalable, allowing manufacturers to customise and expand their testing capabilities as production demands grow. This flexibility is required in an industry where production volumes can vary significantly.

- High Precision and Compliance: Our systems use advanced gases like forming gas, helium blend, or nitrogen for precise leak detection. They are verified to international lab standards and meet automotive standards, providing robust safety and compliance with regulations such as PEDG1, KGS, KHK, ASME, and SELO.

- Turnkey Solutions: Our systems are turnkey, offering a comprehensive solution from loading to unloading. This end-to-end approach simplifies the implementation process and ensures seamless integration into existing production lines.

- Advanced Leak Detection Methods: Our systems employ proven methodologies for leak detection, including pressure decay, vacuum chamber, and accumulation testing. These methods provide accurate, repeatable, and reliable results, ensuring the integrity and safety of hydrogen storage systems.

Preparing for Increased Demand

The ability to scale production efficiently is critical as the hydrogen mobility market expands. VES New Energies’ systems are designed to accommodate increasing production volumes without compromising on safety or performance. Our modular approach allows manufacturers to add modules as needed, ensuring that they can meet future production demands without significant additional investment.

Future-Proofing Production:

- Flexibility in Production Requirements: The modular design of our systems means that they can be customised to meet specific production needs. This flexibility reduces the need for multiple systems or significant reconfiguration, optimising costs and lead times.

- Scalability for Future Growth: Our systems are ready to accept additional modules, ensuring they remain relevant and effective as production scales up. This future-proofing capability provides long-term value and minimises the need for significant future investments.

- Comprehensive Regulatory Support: We provide expert guidance on compliance with diverse regional and international standards, simplifying certification processes and supporting market entry and acceptance.

Paving the Way for Hydrogen Mobility

The hydrogen mobility market is set for a transformative decade, with increasing demand for hydrogen fuel cell vehicles driving the need for advanced hydrogen storage solutions. We are committed to supporting this growth with our innovative, precise, and compliant leak-testing systems. Our modular and scalable designs ensure that manufacturers can meet rising production demands while maintaining the highest standards of safety and compliance.