If you manufacture components for HVAC systems like condensers, evaporators, or manifolds, you already know that reliability and performance are non-negotiable. What’s often underestimated, though, is the role of HVAC Refrigerant Leak Detection in delivering both.

Even the smallest leaks can lead to major issues. From warranty claims and field failures to lost trust and missed compliance marks, undetected leaks can cost more than just time. That’s why more manufacturers are putting leak detection at the heart of their quality process.

Why Small Leaks Matter More Than Ever

Leaks usually aren’t dramatic. They don’t make noise, and they’re rarely visible. But they quietly compromise system performance, increase energy use, and shorten the lifespan of key components. Left unchecked, they become someone else’s problem once the part is installed.

And with newer refrigerants operating at higher pressures and coming under stricter environmental regulation, the need for tight, traceable quality control has never been greater.

Identifying and stopping leaks during production is the smartest way to avoid customer callbacks, failed audits, and costly rework.

Why Traditional Methods Fall Short

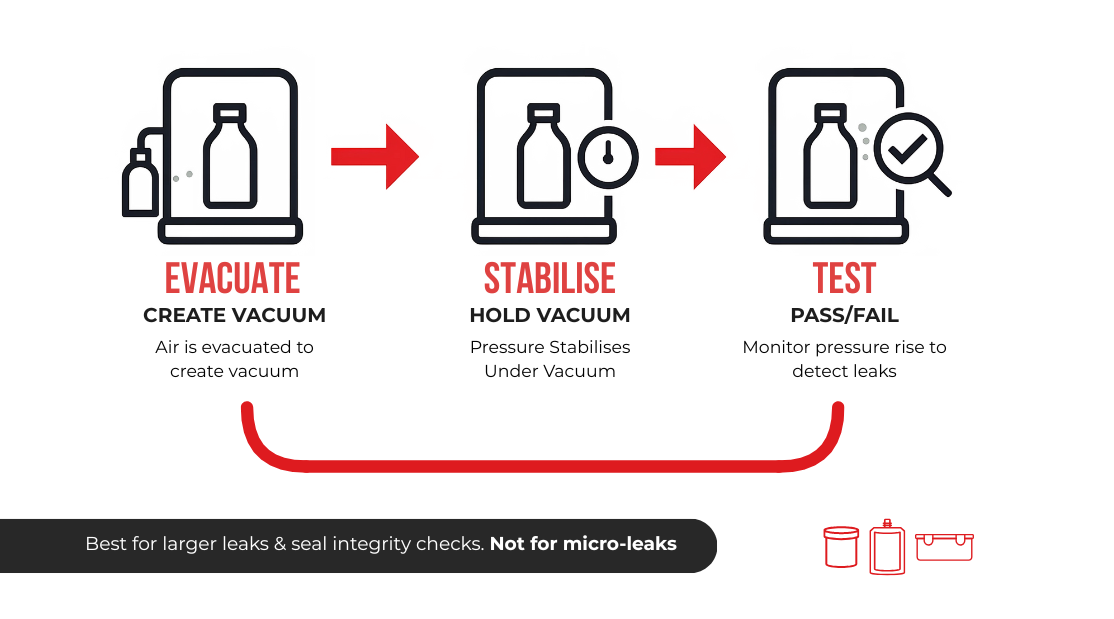

Techniques like pressure decay or bubble testing still have their place, but they’re increasingly falling behind the demands of modern HVAC production. They can be slow, sensitive to environmental factors, and not accurate enough for parts that require high reliability.

Manufacturers today need leak detection solutions that can keep up with production speeds, detect micro-leaks, and deliver results that stand up to regulatory scrutiny.

What Modern Leak Detection Looks Like

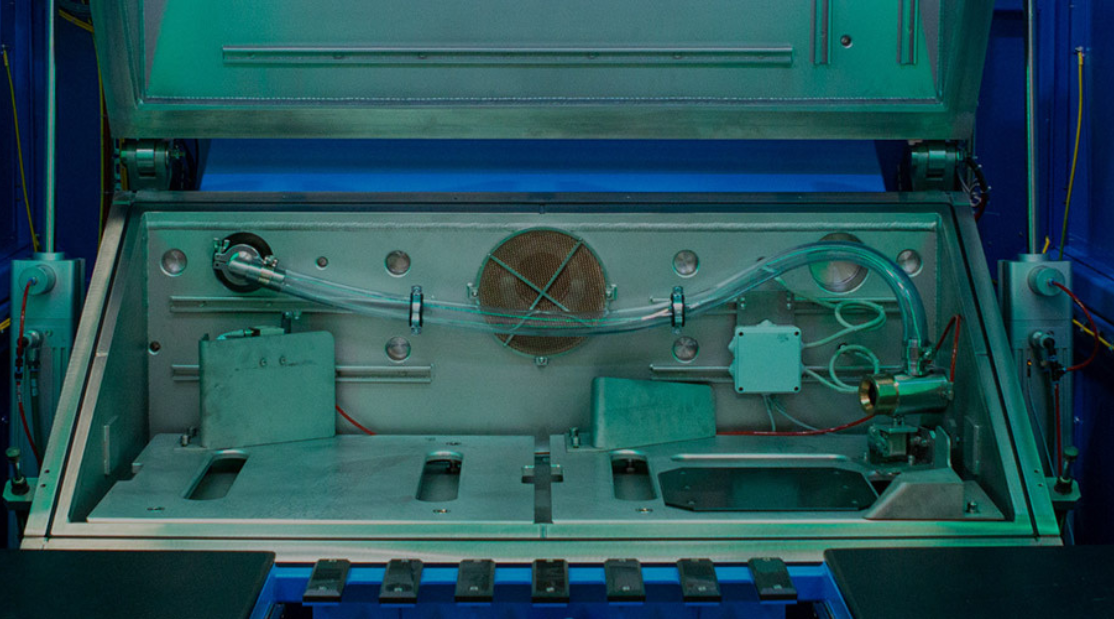

Helium leak testing has become the gold standard for a reason. At VES, we’ve been engineering leak detection systems specifically for the manufacturing environment. Our machines are fast, accurate, and reliable. They can test parts in seconds, integrate directly into production lines, and detect small leaks.

Whether you’re using vacuum or sniffing methods, our systems are built to deliver clean, consistent results with minimal downtime and low helium consumption. They are designed to work as part of your line, not slow it down.

Keeping Up with Changing Regulations

As refrigerants change, so do the rules around them. Alternatives like R744, R1234yf, and other low-GWP options come with tighter leak thresholds. Compliance with standards such as EN 378 or the EU F-Gas Regulation isn’t optional.

That’s where smart HVAC Refrigerant Leak Detection makes all the difference. With built-in data logging, traceability, and CE-marked systems, you can prove your processes are sound and stay ahead of both current and future regulations.

Why Leak Detection Deserves More Attention

Leak detection is no longer just a tick-box on a checklist. It’s a core part of delivering reliable, regulation-ready components. With the right approach to HVAC Refrigerant Leak Detection, you protect your brand, reduce your costs, and build better systems from the ground up.

If you’re ready to modernise your leak testing setup, we’re here to help.