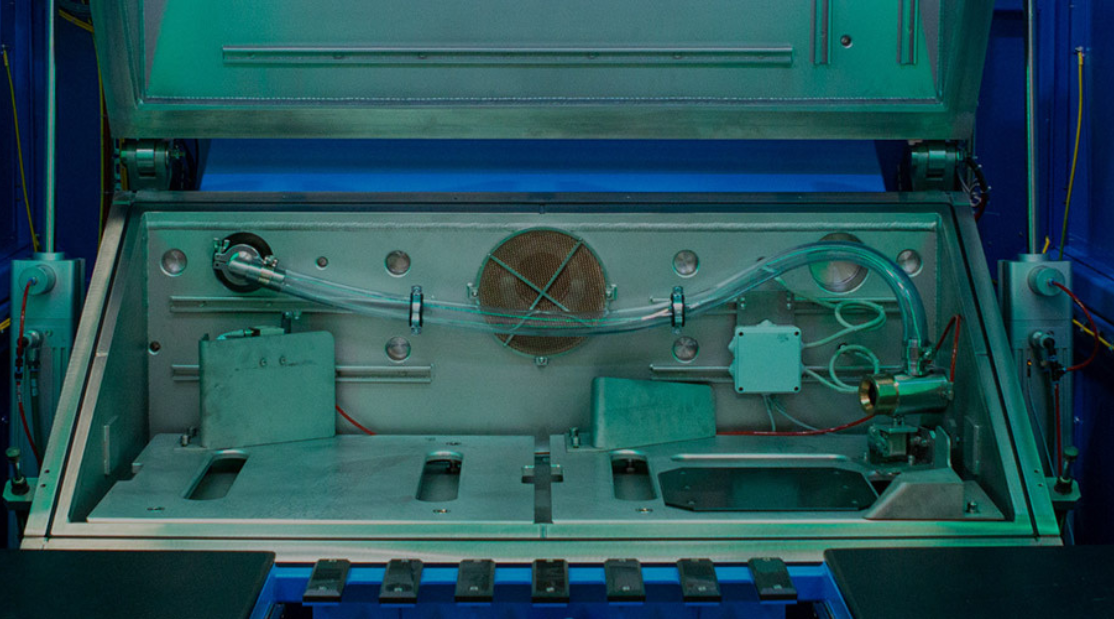

Peter, one of our experienced electrical engineers has been with VES for over 8 years, pictured here wiring the various vacuum pumps required for a double chamber automated helium leak detection system.

The all-important vacuum pumps required a detailed vacuum pump down analysis to select the correct configuration for the leak test system, which is being built for a leading global manufacturer of high-performance sealing systems, fluid transfer systems along with fuel and brake delivery solutions for the automotive industry.

They want to expand their plastic hose production capabilities and require a state-of-the-art automated helium leak detection test line, seamlessly integrating upstream and downstream processes.

A critical requirement is the collection, analysis and presentation of test data to ensure full traceability across the production line. Also, given the variety of hose configurations, lengths and internal volumes, each hose configuration requires its own precise leak test cycle and takt time.

Four dedicated automation stations will be integrated into the leak test system, handling critical tasks such as loading, lifting, moving, marking and rotating the various-sized hose assemblies, ensuring precise positioning and secure connections without manual intervention.

This project demonstrates our commitment to delivering a single-sourced automated leak detection solution, tailored to the specific needs of our customers.

For assistance with our one-stop, single sourced, fully automated end-of-line leak detection solutions designed to reduce production timescales and operating costs – please contact our sales engineers by email at sales@vac-eng.com