The world of leak detection is constantly evolving, with new technologies and methodologies emerging to address the ever-increasing demands for precision, efficiency, and sustainability. Helium leak testing is no exception. As a leading innovator in the field, we’re here to explore the exciting trends that are shaping the future of helium leak testing.

- Rise of Automation and Integration

Manual leak testing, while effective, can be time-consuming and prone to human error. The future lies in automation and integration. We’re witnessing a surge in automated leak testing systems that offer significant advantages. These systems can perform repetitive tasks with exceptional accuracy and consistency, freeing up valuable human resources for more complex tasks. Additionally, seamless integration with production lines allows for real-time leak detection and immediate corrective action, minimising product defects and production delays. Our strategic alliance with ALPHR technology, part of the same group of companies, has given rise to VES automation. Together, we deliver automated leak testing systems designed to meet the diverse needs of modern production environments.

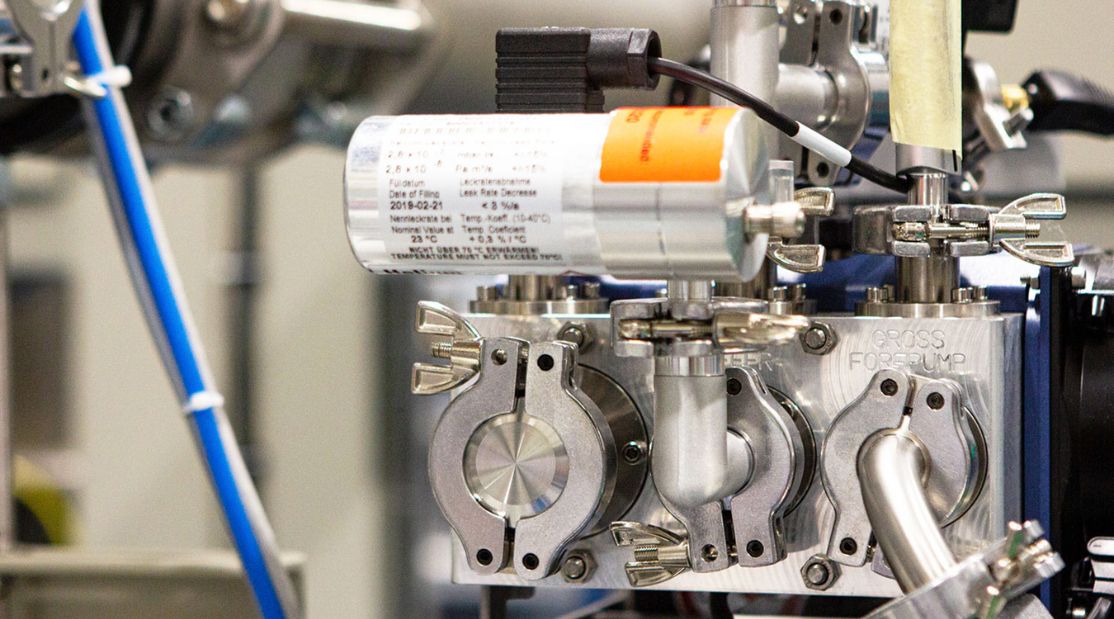

- Advancements in Sensor Technology

The sensitivity and speed of leak detection are directly linked to the capabilities of the mass spectrometer designed to detect minute traces of helium gas. Recent advancements are pushing the boundaries of what’s possible. For example, our engineering teams are continually developing more sensitive and robust helium leak detectors, enabling the detection of even the most minute leaks faster and with greater accuracy. This holds immense potential for industries with stringent leak detection requirements, such as aerospace, medical devices, and semiconductors.

- Focus on Sustainable Practices

Helium is a finite resource, and concerns regarding its long-term availability are prompting a strong focus on sustainable leak testing practices. At VES, we specialise in delivering quality solutions based on our customers’ needs, while prioritising sustainable development. Our strategic framework emphasises People, Environment, and Products & Customers. In line with this framework, we’re developing alternative tracer gases like hydrogen and nitrogen, which offer promising results. Although helium remains the gold standard, we are innovating our systems to minimise its use per test, thus promoting sustainability.

- The Power of the Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is revolutionising various industries, and leak detection is no different. VES Connect, our innovative cloud monitoring service, leverages the power of IIoT by seamlessly integrating leak-testing equipment into a network. This allows for real-time data collection and analysis, offering valuable insights into leak trends, identifying potential equipment issues, and enabling predictive maintenance. With VES Connect, this proactive approach minimises downtime and optimises the leak detection process.

- Artificial Intelligence (AI) for Enhanced Leak Detection

The power of Artificial Intelligence (AI) is finding its way into leak detection. AI algorithms can analyse vast amounts of data collected during leak tests, identifying patterns and anomalies that might be missed by traditional methods. This allows for early detection of potential leaks and even enables the prediction of future leak occurrences, leading to a more preventative approach to leak management.

Commitment to Innovation

At VES, we are at the forefront of these exciting advancements. We are committed to continuous innovation, developing excellent leak-testing solutions that cater to the evolving needs of our customers. From advanced automation to integration with IIoT and AI-powered leak analysis, we strive to provide our customers with the most efficient, reliable, and sustainable helium leak testing solutions available. As the future of leak detection unfolds, VES remains your trusted partner, ensuring the integrity and quality of your products.